Injectable medicated particle-inlaid porous composite microsphere preparation and preparation method thereof

A technology of porous composite microspheres and porous microspheres, applied in the field of medicine, can solve the problems of sudden release of growth factors or chemical drugs, difficulty in controlling the pore structure, and poor mechanical strength of the gel, so as to reduce systemic side effects and avoid sudden release , Improve the effect of repairing curative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

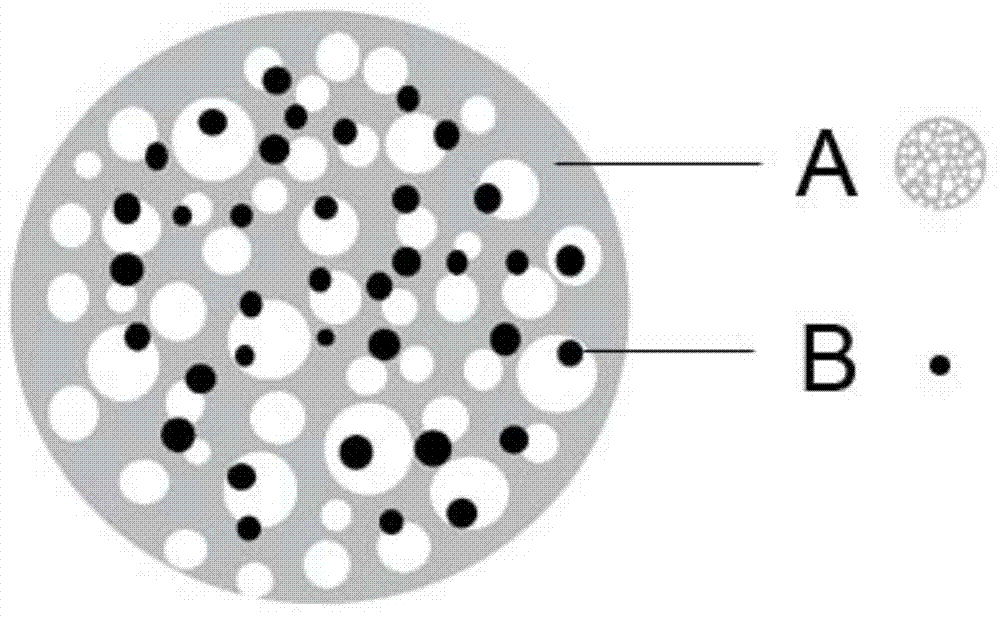

[0067] Example 1: Preparation of PLGA porous composite microspheres containing model drug bovine serum albumin (Bovine serum albumin, BSA) chitosan microspheres

[0068] A, prepare chitosan microspheres containing BSA:

[0069] According to literature reports (Kim SE, Park JH, Cho YW, Chung H, Jeong SY, Lee EB, et al. Porous chitosan scaffold containing microspheres loaded with transforming growth factor-beta1: implications for cartilage tissue engineering. Journal of controlled release: official journal of the Controlled Release Society.2003;91:365-74), prepared by the following method: weigh 120mg chitosan (molecular weight 100000, Zhejiang Jinke Biochemical Co., Ltd.), add 3mL 2% (V / V) acetic acid aqueous solution After vortexing to dissolve, add 1 mL of 0.5% (W / V) model drug bovine serum albumin (Amresco, USA) aqueous solution, mix well and drop into 90 mL of n-octanol (containing 4% Span 80, V / V), after stirring at 1200 rpm for 30 minutes, 10 mL of 5% (W / V) sodium tripol...

Embodiment 2

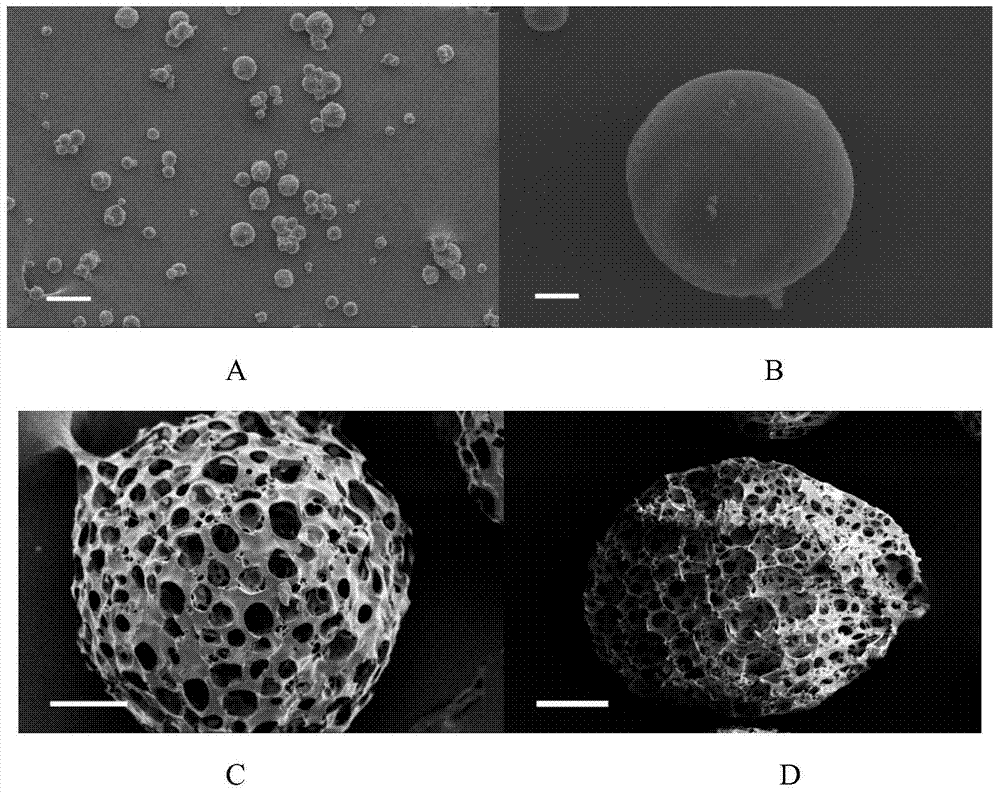

[0072] Example 2: Morphological observation of PLGA porous composite microspheres embedded with BSA-containing chitosan microspheres

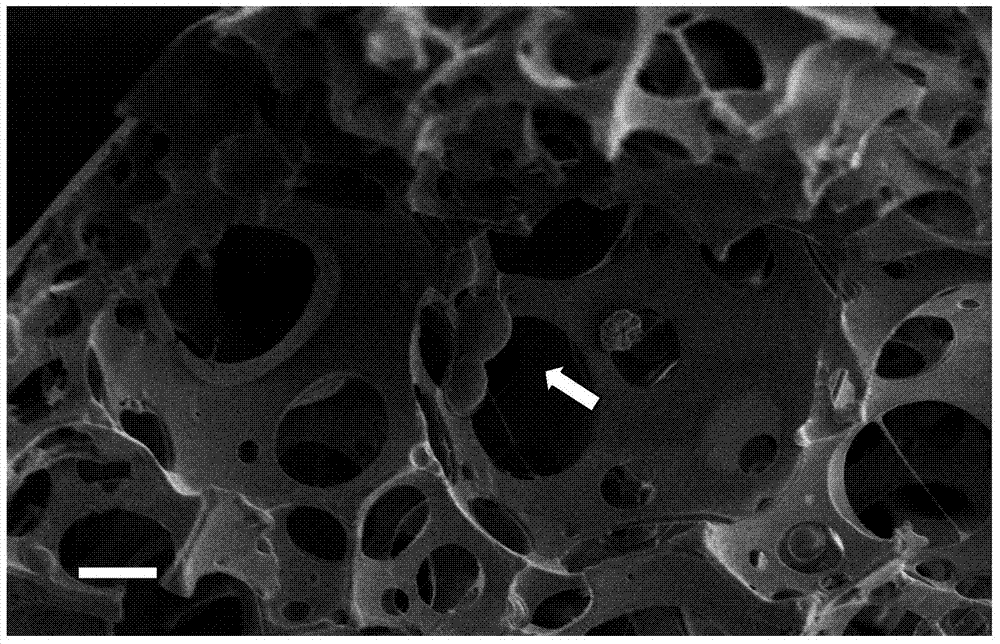

[0073] Get the BSA chitosan microspheres prepared in a certain amount of embodiment 1 and the PLGA porous microspheres containing BSA chitosan microspheres, place on the sample plate that is glued with double-sided adhesive tape, after gold plating, scan electron microscope ( ZESSMA10, Germany) was observed to obtain chitosan microspheres ( figure 2 A, B, the scales are 50 μm and 5 μm respectively) and PLGA porous composite microspheres containing BSA chitosan microspheres ( figure 2 C, D, scale 100 μm) Morphology and distribution of chitosan microspheres in porous microspheres ( figure 2 , scale bar 10 μm).

[0074] The shape of chitosan microspheres is round and the surface is smooth, as shown in Figure 2A and B. The shape of PLGA porous microspheres is round, and a large number of pores are randomly distributed on the surface, such as ...

Embodiment 3

[0075] Embodiment 3: the particle size determination of the PLGA porous composite microspheres embedded with BSA chitosan microspheres

[0076] The PLGA porous composite microspheres embedded with BSA chitosan microspheres prepared by Example 1 are dispersed in deionized water, and their particle diameters are measured with Malvern Masersizer2000 ( Figure 4 A). Randomly select 3 microspheres from the scanning electron microscope photos of porous microspheres, measure their surface pore size (negligible if the pore size is less than 5 μm), and take the average value. The pore size distribution diagram is as follows: Figure 4 Shown in B. Measure the particle diameter of the microspheres on the scanning electron microscope photo containing BSA chitosan microspheres, get the average value ( Figure 4 C).

[0077] Such as Figure 4 As shown in A, the average particle size of the PLGA porous composite microspheres embedded with BSA-containing chitosan microspheres is 353.32±35...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com