Method and device for removing trihalomethanes in drinking water by plasma

A trihalomethane and plasma technology, applied in the field of water treatment, can solve the problems of low removal efficiency, air pollution, long treatment time, etc., and achieve the effects of easy industrial amplification, broad application prospects and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

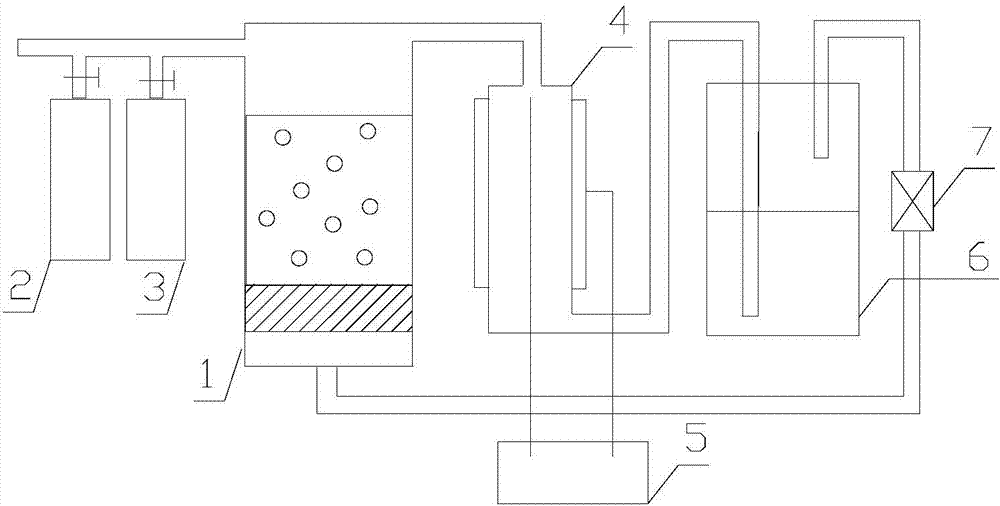

Embodiment 1

[0031] Add 10L of drinking water to the reactor 1 with a total volume of 15L; open the oxygen cylinder 2 and the argon cylinder 3, and charge 10L of gas into the reactor 1, the pressure in the reactor 1 is 1 atmosphere, and the balance of oxygen and argon The volume ratio is 1.0%; the gas circulation pump 7 is turned on, so that the trihalomethanes in the water are brought into the gas discharge tube 4; the high-frequency power supply 5 is turned on, the gas is broken down, and plasma is formed in the gas discharge tube 4, and the influent is treated. deal with. The experimental conditions are as follows: the material of the gas discharge tube 4 is quartz, the tube diameter is 20mm, the length is 20cm, the discharge gap is 1.5mm, the inner electrode is copper tube, the outer electrode is aluminum foil, the power frequency is 1000Hz, the power is 50W, the gas flow rate is 25ml / s, alkali The concentration of sodium hydroxide in the liquid tank is 2.0mol / L, and the volume is 200m...

Embodiment 2

[0035] Add 8.0L of drinking water to Reactor 1 with a total volume of 10L; open the cylinders of oxygen and argon, and fill 2.0L of gas into Reactor 1, the pressure in Reactor 1 is 1 atmosphere, and the volume of oxygen and argon The ratio is 0.5%; turn on the gas circulation pump, so that trihalomethanes in the water are brought into the discharge tube; turn on the high-frequency power supply, the gas is broken down, and plasma is formed in the discharge tube to treat the influent water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com