Method for implementing rapid start of short-cut nitrification and denitrification to treat wastewater by preposed pre-oxidation

A short-range nitrification, quick-start technology, applied in oxidized water/sewage treatment and other directions, can solve the problems of secondary pollution, weak system impact resistance, large aeration tank, etc., to reduce toxicity, improve biodegradability, and improve biochemical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

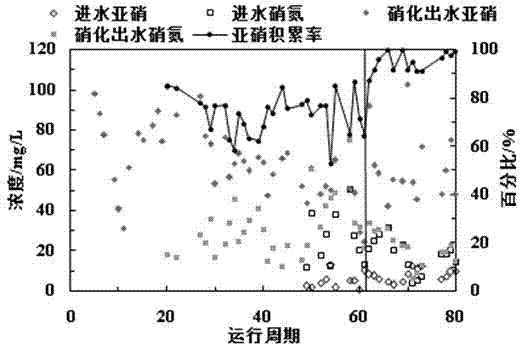

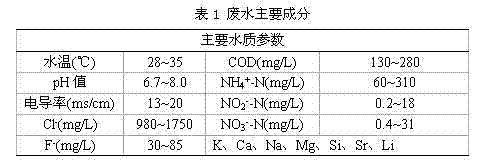

[0034] The inoculation sludge is the return sludge of the catalyst production wastewater treatment unit of a petrochemical company's refinery sewage treatment plant. The inoculation volume is 0.8L. The sludge concentration in the reactor after inoculation is 3257mg / L. Run the reactor. Catalyst wastewater is high-ammonia-nitrogen, low-carbon wastewater, and contains a large amount of salt, macromolecular organic matter and reducing substances that are difficult to be utilized by biology. The water quality is complex and difficult to treat. The main water quality indicators are shown in Table 1. The operation effect is as follows figure 2 As shown, domestic sewage is municipal sewage in the plant area.

[0035]

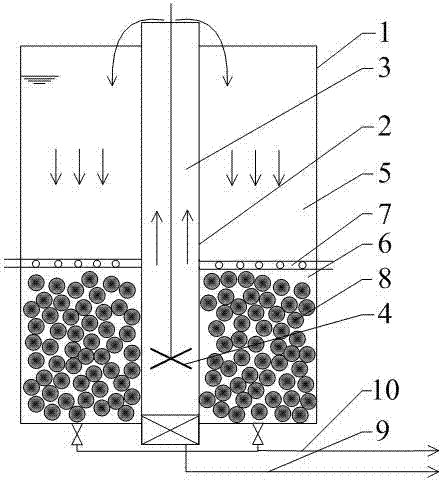

[0036] In the process of wastewater treatment, the wastewater enters the pre-oxidation zone of the reactor through the inlet pipe of the reactor, and acetic acid and domestic sewage are added to the wastewater to moderately oxidize it. The acetic acid and domestic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com