Preparation method of lithium ion battery silicon-carbon composite cathode material

A technology of lithium ion battery and negative electrode material, applied in the field of electrochemical power supply, can solve the problems of unstable motor cycle performance, easy agglomeration of nano-silicon materials, battery failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

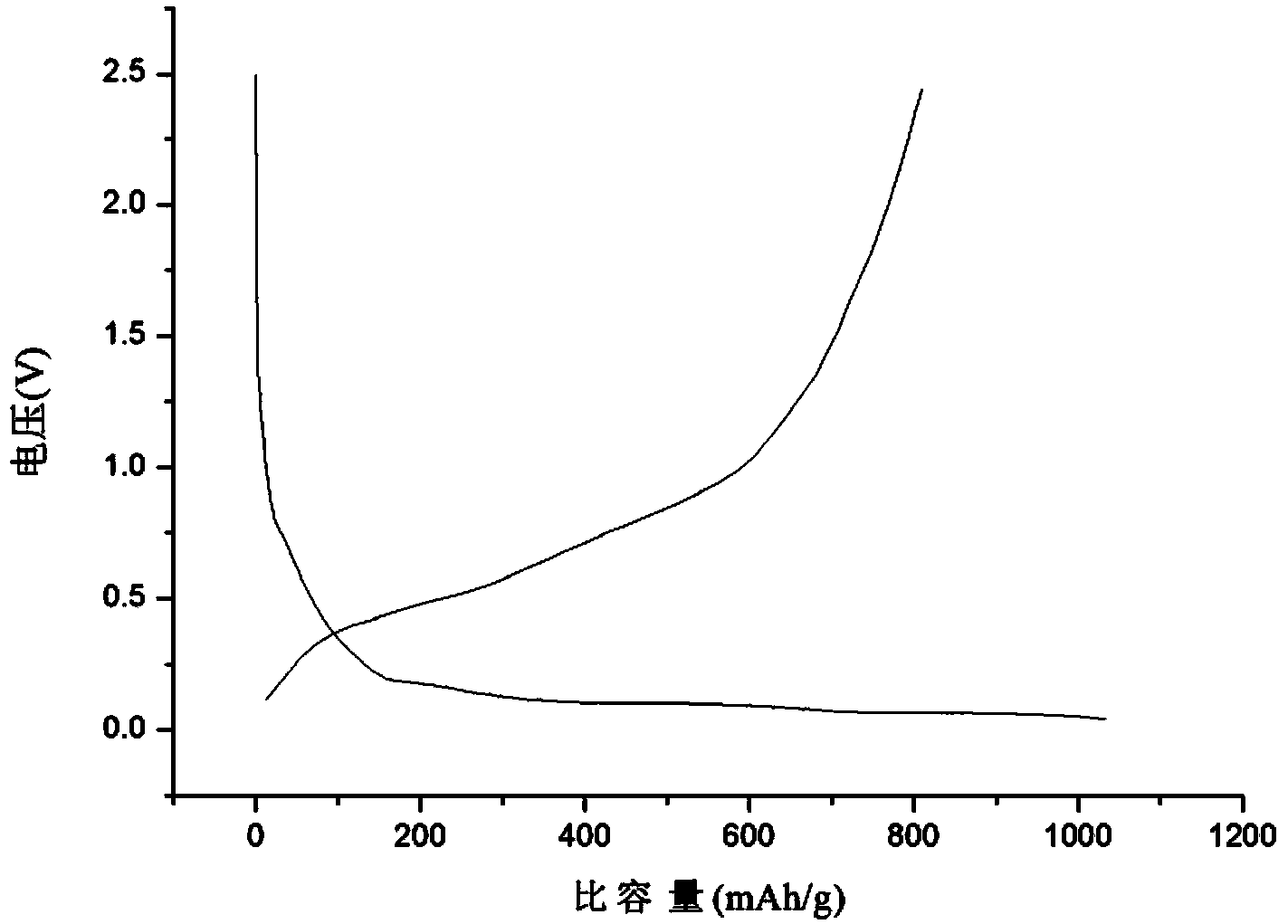

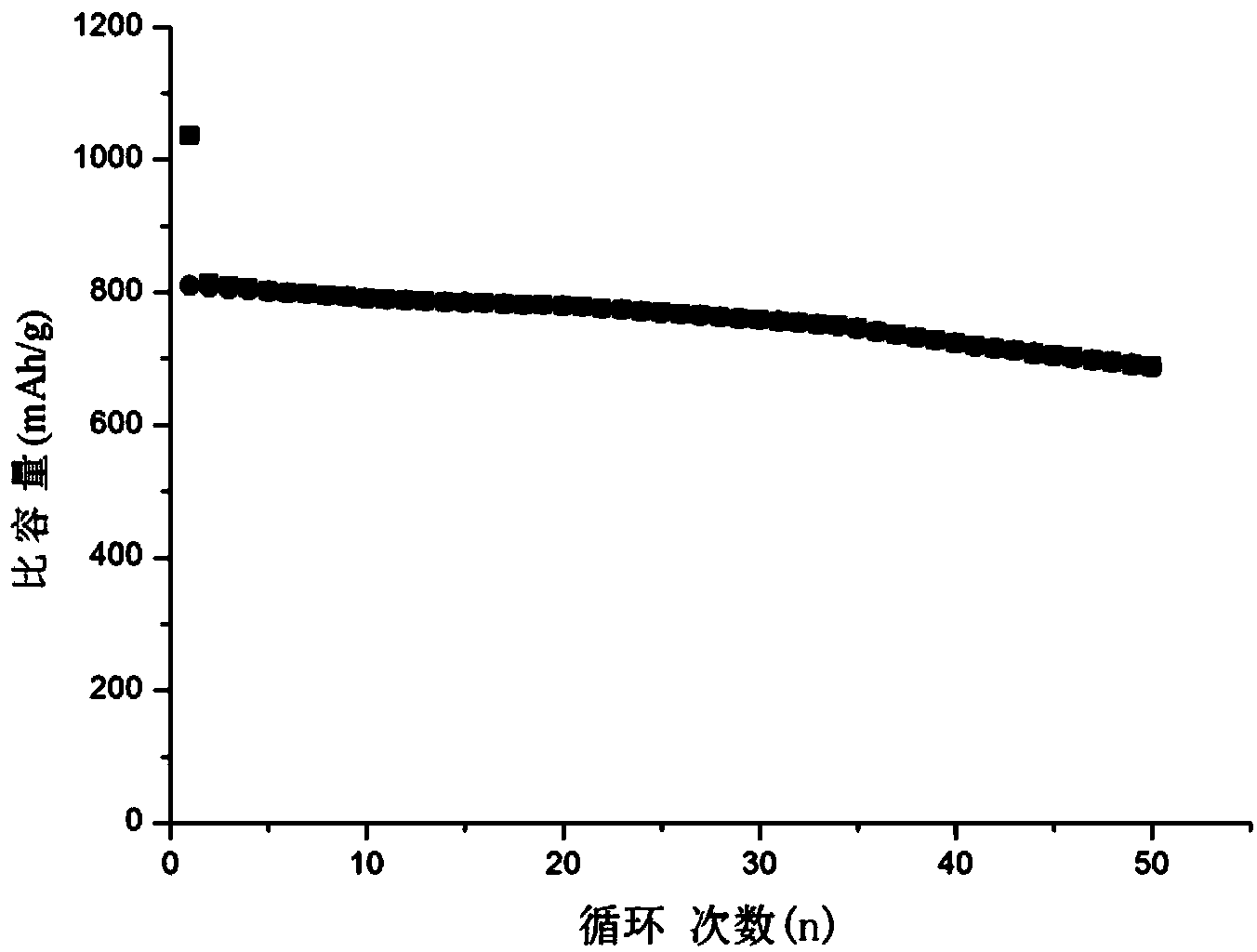

[0020] Measure 45ml of tetraethyl orthosilicate and dissolve in 12ml of absolute ethanol, then add 15ml of deionized water, stir evenly to form a transparent solution, add dropwise oxalic acid, adjust the pH value of the solution to 4; add 22.4g of mesophase carbon microspheres (D50 12um), high-speed magnetic stirring at 50°C for 2.5h, slowly adding 10% ammonia water until the gel is complete; dry the gel in an oven at 105°C to obtain a silica / graphite composite material. Put the obtained silica / graphite composite material in a tube furnace, feed a mixture of propylene gas and argon gas (5% vol propylene) at 750°C for 3.5 hours, then change to argon, and raise the temperature to 1100°C , keep warm for 5h, and cool with the furnace to obtain silicon / graphite / amorphous carbon composite negative electrode material. The prepared composite material, acetylene black, and PVdF were made into a slurry according to the mass ratio of 80:10:10, and evenly coated on the copper foil (14um)...

Embodiment 2

[0022] Measure 45ml tetraethyl orthosilicate and dissolve in 12ml absolute ethanol, then add 15ml deionized water, stir well to form a transparent solution, add dropwise oxalic acid, adjust the pH value of the solution to 4; add 13.1g natural graphite (D50 is 8um) , high-speed magnetic stirring at 53°C for 2h, slowly adding 10% ammonia water until the gel was completed; the gel was dried in an oven at 105°C to obtain a silica / graphite composite material. Put the obtained silica / graphite composite material in a tube furnace, feed the mixed gas of propylene and argon (5% propylene) at 750°C for 3.5 hours, then change to argon, and raise the temperature to 1150°C , keep warm for 4h, and cool with the furnace to obtain silicon / graphite / amorphous carbon composite negative electrode material. The prepared composite material, acetylene black, and PVdF were made into a slurry according to the mass ratio of 80:10:10, and evenly coated on the copper foil (14um). After drying, it was pun...

Embodiment 3

[0024] Dissolve 45ml of tetraethyl orthosilicate in 12ml of absolute ethanol, then add 15ml of deionized water, stir well to form a transparent solution, add dropwise oxalic acid, adjust the pH value of the solution to 4; add 8.4g of mesophase carbon microspheres (D50 8um), high-speed magnetic stirring at 55°C for 1h, slowly adding 10% ammonia water until the gel was completed; the gel was dried in an oven at 105°C to obtain a silica / graphite composite material. The obtained silica / graphite composite material was placed in a tube furnace, and a mixture of propylene gas and argon gas (5% vol propylene) was introduced at 750°C for 6 hours, and then argon was changed, and the temperature was raised to 1150°C. Keeping the temperature for 6 hours and cooling with the furnace to obtain the silicon / graphite / amorphous carbon composite negative electrode material. The prepared composite material, acetylene black, and PVdF were made into a slurry according to the mass ratio of 80:10:10,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com