Preparation method of silicon and silicon doped nanosheet

A technology of nanosheets and doping elements, which is applied in the field of preparation of silicon and its doped nanosheets, can solve the problems of limiting the practical application of silicon nanosheets, impure products, complex processes, etc., and achieve no harmful substances and low cost , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The high-purity silicon block is used as the anode, and the tungsten rod is used as the cathode, and the distance between the two electrodes is adjusted to 30mm. Vacuum the reaction chamber to about 10 -2 Pa, filled with argon and hydrogen at a ratio of 2:1 to reach 2×10 4 Pa and 1×10 4 Pa. Turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the two electrodes and stabilize the arc, evaporate the bulk target, form atomic clusters and gather them into nanosheets and deposit them on the wall of the reaction chamber, and collect the powder through passivation process.

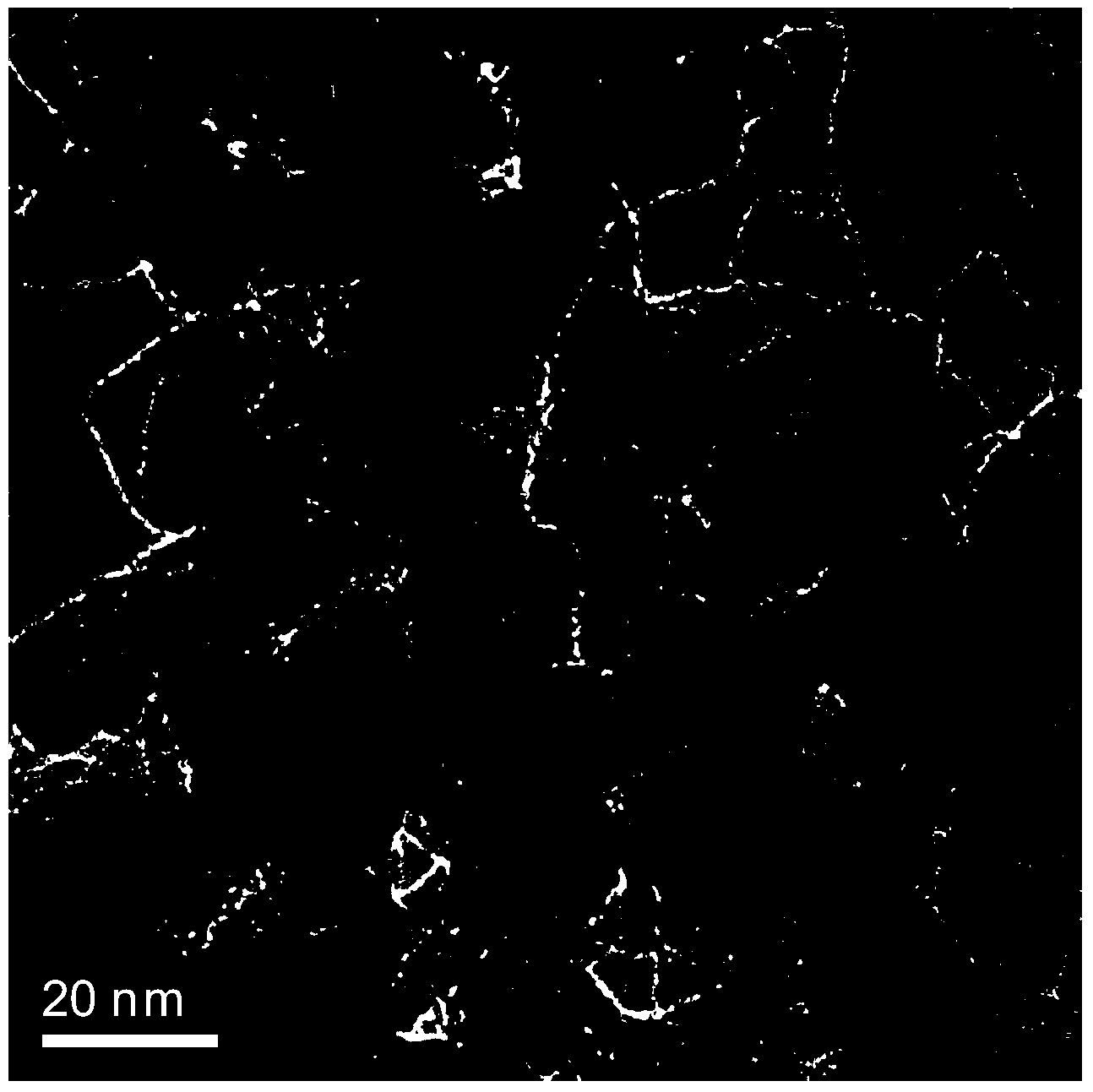

[0023] The TEM image of silicon nanosheets obtained in Example 1 is as follows figure 1 Shown, appear as nanosheets.

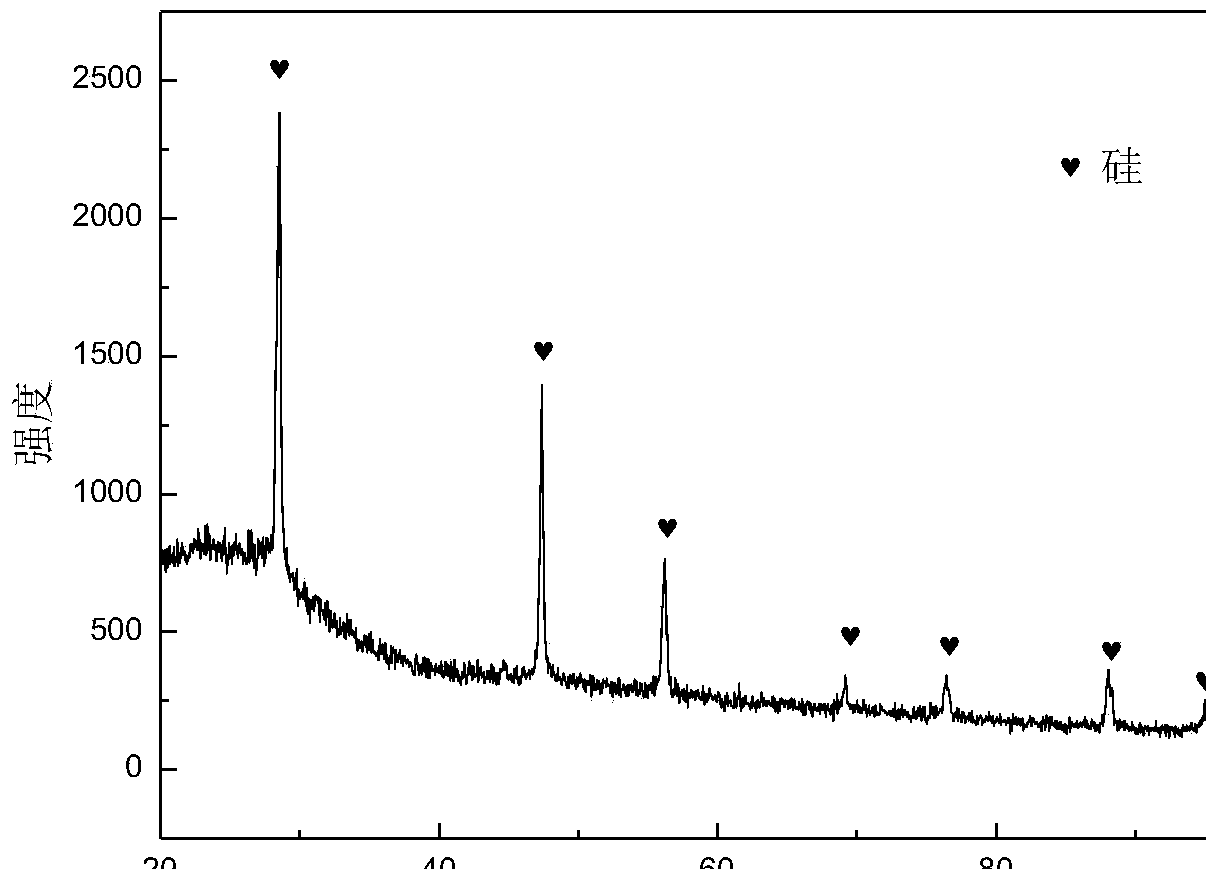

[0024] The obtained silicon nanosheet XRD pattern of embodiment 1 is as follows figure 2 As shown, it is shown as single-phase silicon.

[0025] The silicon nanosheets obtained in Example 1 have a thickness of about 1.5 n...

Embodiment 2

[0027] The high-purity silicon block is used as the anode, and the tungsten rod is used as the cathode, and the distance between the two electrodes is adjusted to 30mm. Vacuum the reaction chamber to about 10 -2 Pa, filled with helium and hydrogen at a ratio of 2:1 to reach 2×10 4 Pa and 1×10 4 Pa. Turn on the cooling water system, turn on the power and start the arc, adjust the current and the distance between the two electrodes and stabilize the arc, evaporate the bulk target, form atomic clusters and gather them into nanosheets and deposit them on the wall of the reaction chamber, and collect the powder through passivation process. Compared with the silicon nanosheets prepared in Example 1, the silicon nanosheets prepared in Example 2 are narrower and have a ribbon-like morphology.

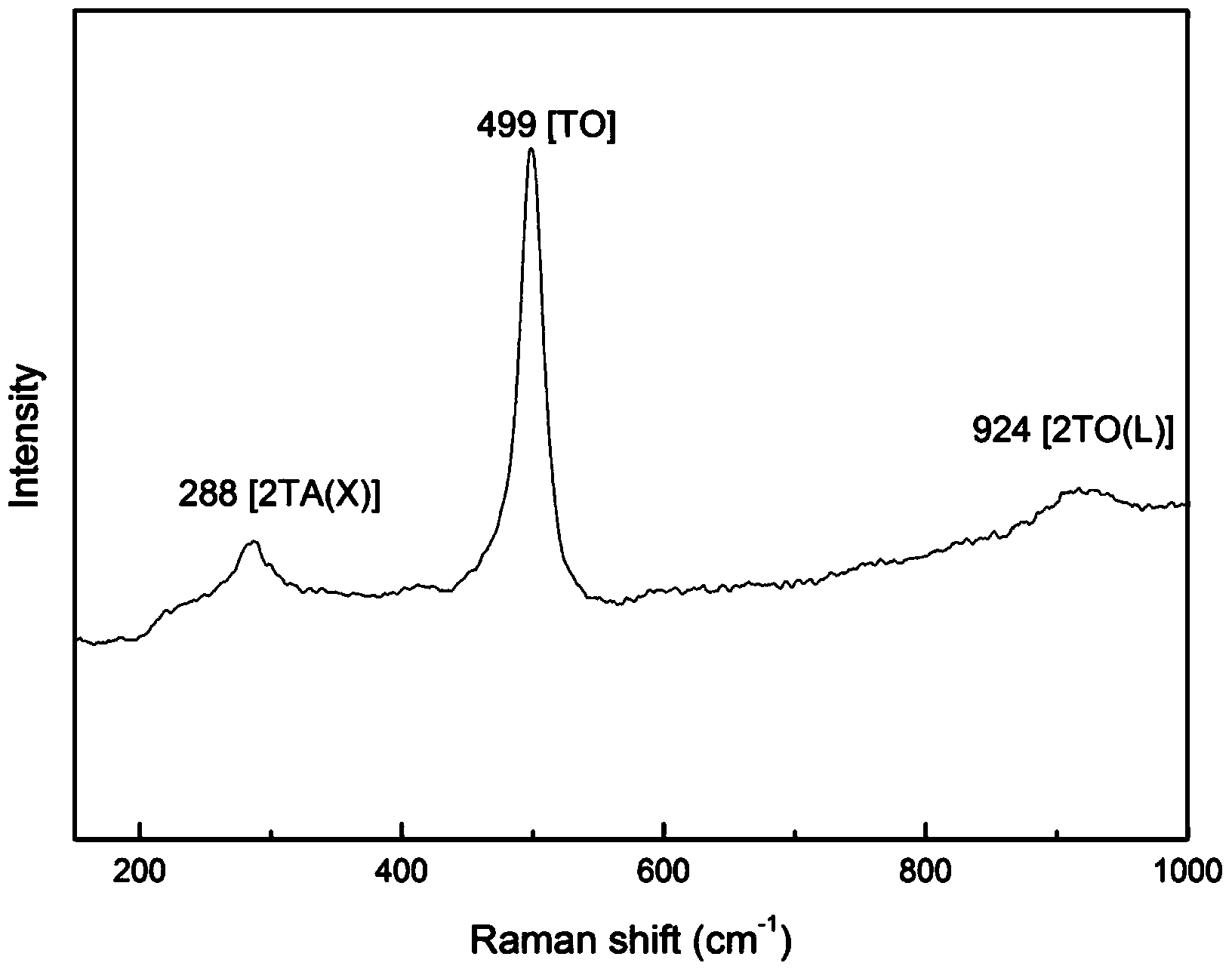

[0028] The obtained silicon nanosheet Raman collection of illustrative plates of embodiment 2 is as image 3 , showing the second-order vibration characteristic peaks of the two-dimensional...

Embodiment 3

[0030] Mix and grind the silicon nanosheets prepared in Example 1, conductive agent and sodium carboxymethyl cellulose with a mass ratio of 45:45:10, add an appropriate amount of deionized water dropwise, and stir to obtain a viscous slurry, which is coated on the pre- On the pressed copper foil, dry in vacuum at 120°C for 10h. Then transfer the electrode sheet to a glove box filled with argon (Ar2 <0.1ppm), the lithium sheet is used as the counter electrode, the electrolyte is 1M LiTFSI, the separator is Ceglard2400 microporous polypropylene membrane, and the CR2025 button half-cell is assembled. CHI660D-1 electrochemical workstation (Shanghai Chenhua Instrument Co., Ltd.) was used to conduct cyclic voltammetry test with a scanning speed of 0.0001V / S and a voltage range of 0.01-2.5V. Using Land CT2001A (Wuhan Landian Electronics Co., Ltd.) for cycle performance test, the voltage range is 0.01-1.2V.

[0031] The lithium-ion battery cycle performance curve that embodiment 3 ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com