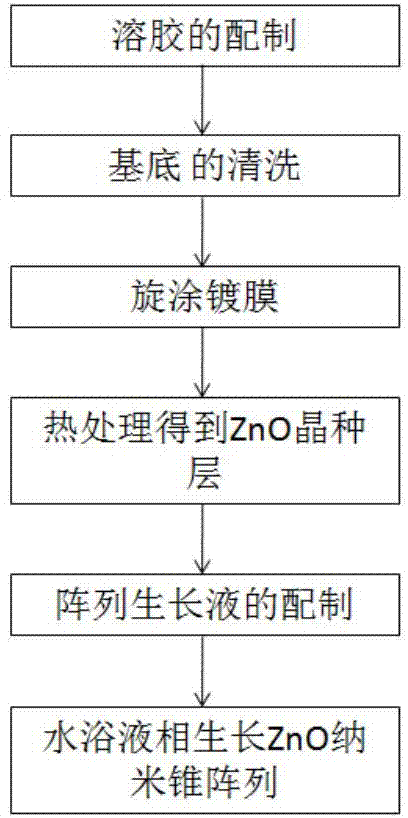

Preparation method of height-oriented ZnO nanocone array structure material

A technology of array structure and nano-cones, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high reaction temperature and insufficient uniformity, and achieve good repeatability and uniform thickness , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] ③Preparation of seed layer: Prepare a layer of ZnO colloidal film on the cleaned substrate (such as Cu sheet or FTO glass) by spin-coating method; after annealing at 350°C for 10 minutes, a uniform and dense layer is formed on the surface of the substrate. Nanoscale ZnO seed layer.

[0038] ④ Preparation of array growth solution: use KOH and Zn(NO 3 ) 2 The preparation concentration is 0.10~0.25mol L -1 Zn(OH) 4 2- aqueous solution, and the pH value of the solution is controlled between 10 and 12, and fully magnetically stirred to obtain a clear solution, which is the required array growth solution.

[0039] ⑤ Preparation of the array: Pour the array growth solution into the reaction container, and then suspend the substrate with the seed layer prepared downward in the array growth solution (such as Figure 8 shown), then seal the reaction vessel, place it in an electric heating constant temperature water bath, keep it warm for 1-12 hours in a water bath at 20-50°C...

Embodiment 1

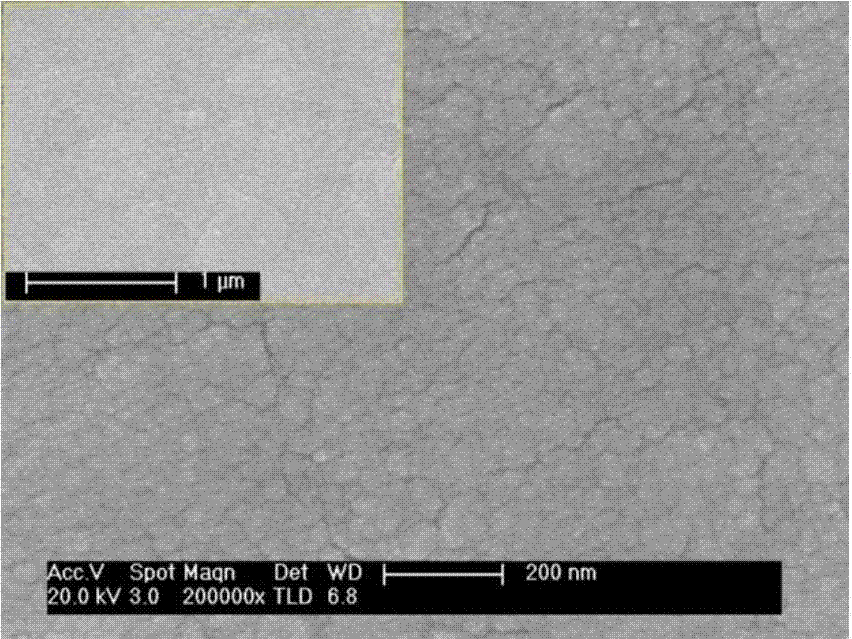

[0041] Embodiment 1: Preparation of base seed crystal layer

[0042] Using the pre-prepared colloid above, a layer of ZnO colloid film was prepared on the Cu substrate by using a KW-4A desktop colloidal machine for spin coating; annealing at 350°C for 10 minutes in an argon atmosphere formed a layer of ZnO colloid on the surface of the substrate. Uniform and dense nano-scale ZnO seed crystal layer, such as image 3 shown.

Embodiment 2

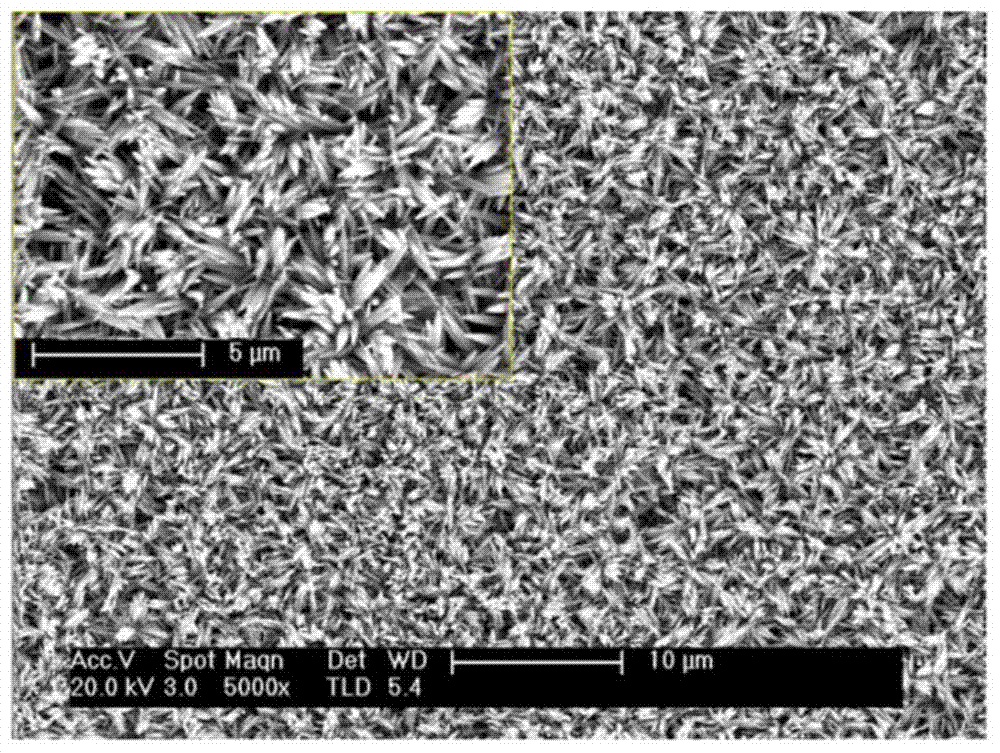

[0043] Embodiment 2: Cu substrate grows ZnO nano cone array at 35 ℃

[0044] Adopt the substrate placing method described in the present invention, in by KOH and Zn(NO 3 ) 2 Prepared 0.25mol·L with pH=12 -1 Zn(OH) 4 2- In the reaction system, the ZnO array thin films prepared after growing in a water bath at 35°C for 4h, 8h, and 12h with the Cu sheet prepared with a seed layer as the substrate, the morphologies are as follows: Figure 4 , Figure 5 , Image 6 shown. The FESEM results of the sample show that ZnO is cone-shaped and nanoscale, showing a high degree of preferred orientation; the overall array is good. Sample XRD grown for 12h ( Figure 7 ) results show that the obtained array composition is the ZnO phase with hexagonal wurtzite structure, and the spectrum is completely consistent with the diffraction data of the standard card (PDF#36-1451). Compared with the standard spectrum of ZnO powder, the (002) diffraction peak has a relative The higher intensity in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com