High-temperature resistance metal ceramic solar energy selective absorbing coating and preparing method

A cermet and absorption coating technology, which is applied in metal material coating process, solar thermal power generation, metal layered products, etc. The effect of stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

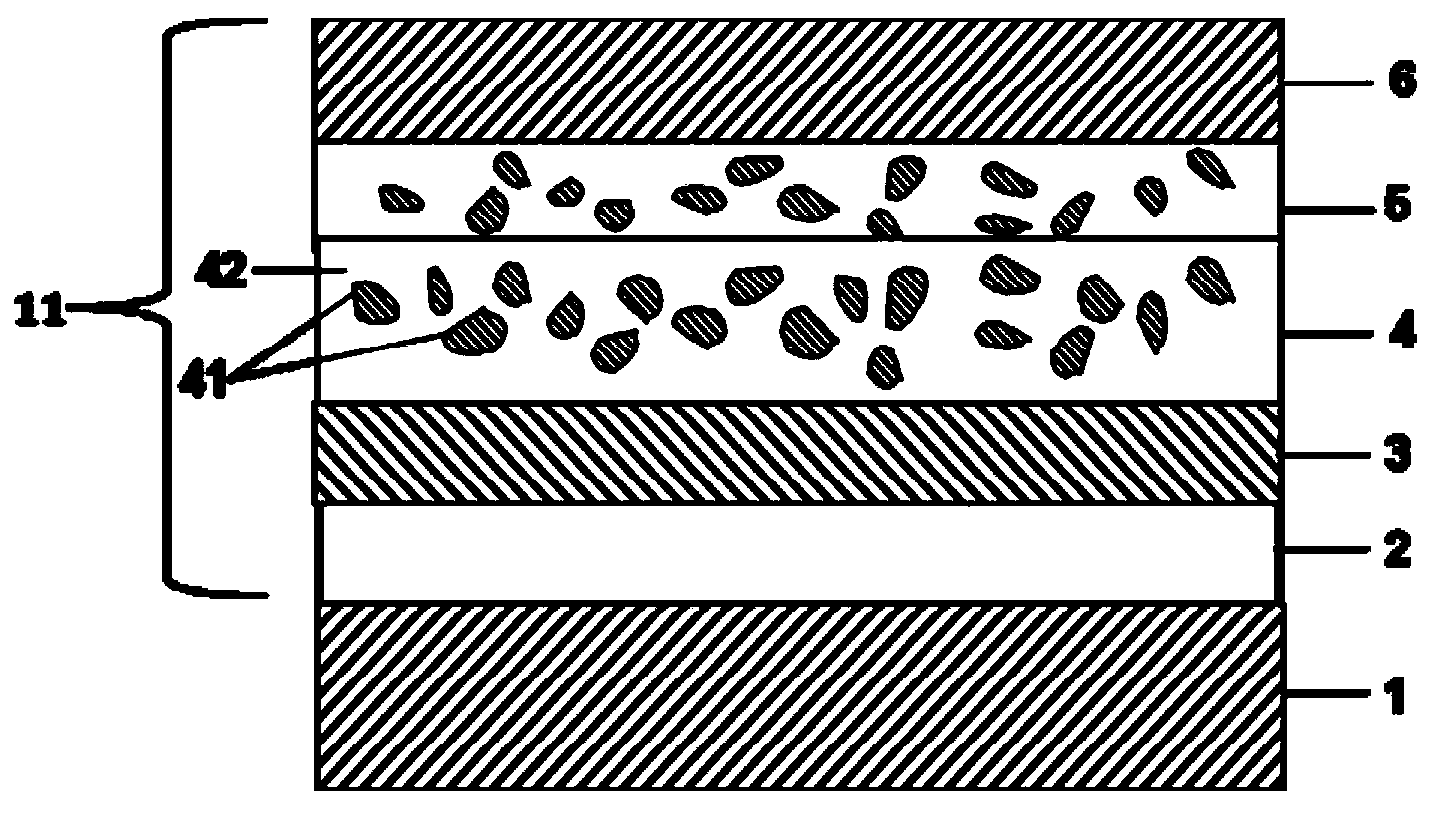

Method used

Image

Examples

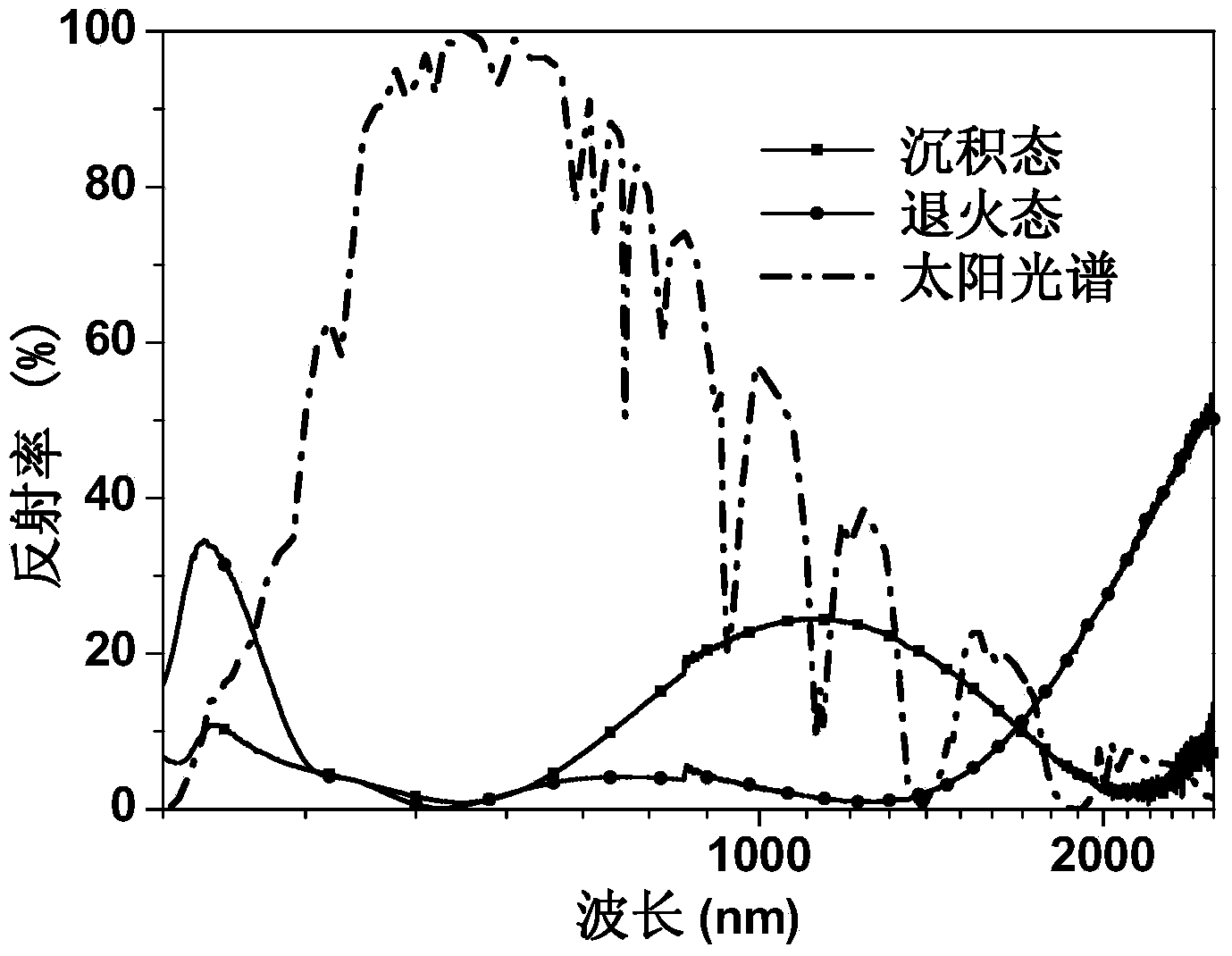

Embodiment 1

[0035] Place the quartz wafer and (100) single crystal silicon wafer to be plated in the deposition chamber, pre-evacuate, and the background vacuum is 4×10 -4 Pa, heat the quartz sheet and (100) single crystal silicon sheet to make the temperature 150oC, and at the same time pass Ar gas to raise the pressure of the vacuum chamber to 0.45Pa, keep it warm for 50min for desorption, and remove the impurities physically adsorbed on the surface of the substrate. It is beneficial to improve the bonding force between the film and the substrate; then close the introduction of Ar gas, and re-pump the deposition chamber to 1.8×10 -4 Pa, and re-introduce Ar gas to increase the pressure of the deposition chamber to 0.45Pa again; turn on the substrate RF bias, set its power to ~120W and glow, sputter for 15min, and further clean the substrate surface; turn off the cleaning bias At the same time, turn on the driving power of the Ag target and the Al target, adjust its power to 60W, and pre-...

Embodiment 2

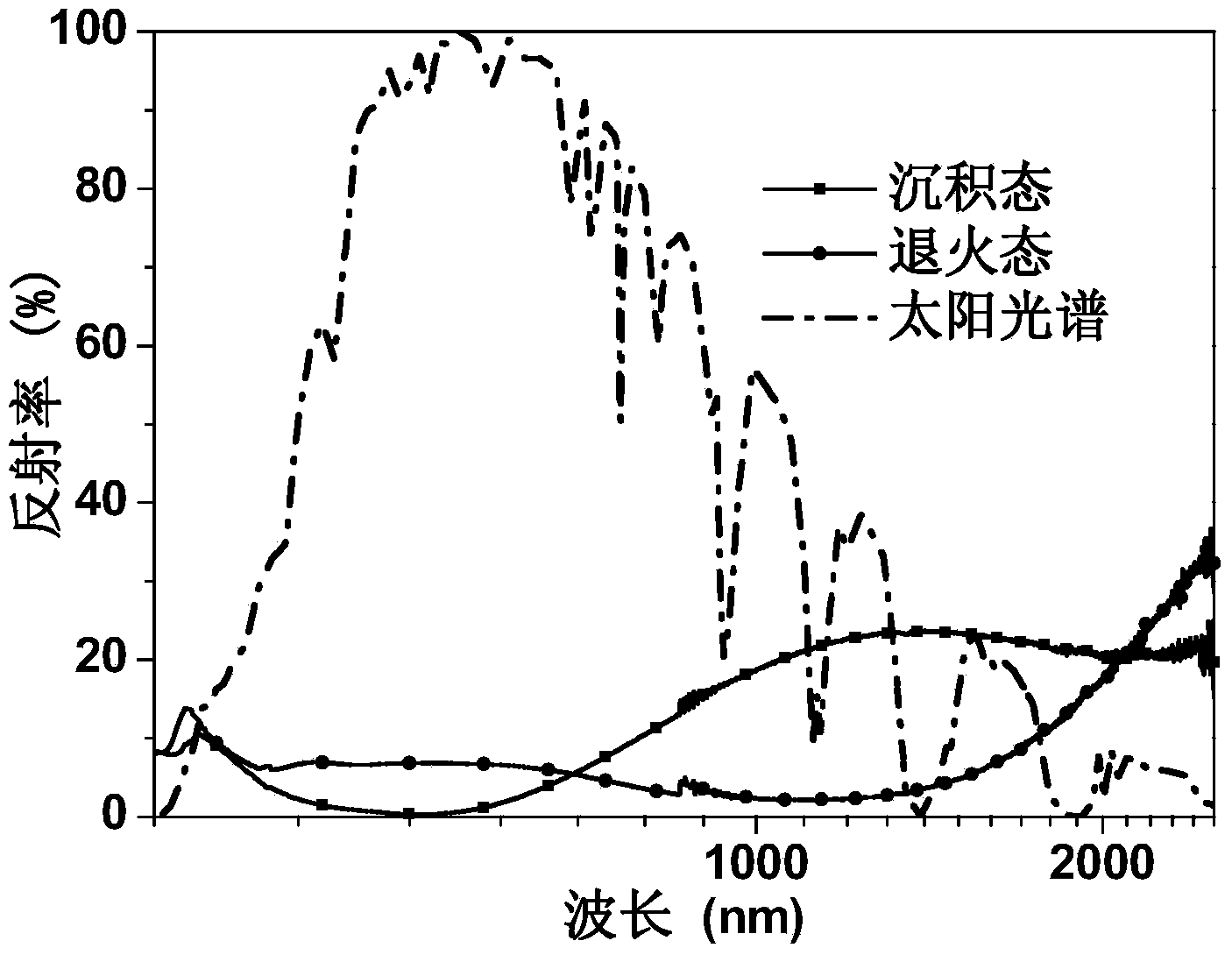

[0038] Place the quartz sheet and thermally oxidized stainless steel sheet to be plated in the deposition chamber, pre-evacuate, and the background vacuum is 4.3×10 -4 Pa, heat the quartz sheet and the thermally oxidized stainless steel sheet to 150oC, and at the same time pass in Ar gas to increase the pressure of the vacuum chamber to 0.45Pa, keep it warm for 50min for desorption, remove the impurities physically adsorbed on the surface of the substrate, and facilitate the promotion of the film The binding force between the substrate and the substrate; then the Ar gas is closed, and the deposition chamber is re-pumped to 2×10 -4 Pa, and re-introduce Ar gas to increase the pressure of the deposition chamber to 0.45Pa again; turn on the substrate RF bias, set its power to ~120W and glow, sputter for 15min, and further clean the substrate surface; turn off the cleaning bias At the same time, turn on the driving power of the Ag target and the Al target, adjust the power to 60W, ...

Embodiment 3

[0041] Place the quartz sheet and ordinary soda-lime glass sheet to be plated in the deposition chamber, pre-evacuate, and the background vacuum is 3.7×10 -4 Pa, heat the quartz sheet and (100) single crystal silicon sheet to make the temperature 150oC, and at the same time pass Ar gas to raise the pressure of the vacuum chamber to 0.45Pa, keep it warm for 50min for desorption, and remove the impurities physically adsorbed on the surface of the substrate. It is beneficial to improve the bonding force between the film and the substrate; then close the introduction of Ar gas, and re-pump the deposition chamber to 1.6×10 -4 Pa, and re-introduce Ar gas to increase the pressure of the deposition chamber to 0.45Pa again; turn on the substrate RF bias, set its power to ~120W and glow, sputter for 15min, and further clean the substrate surface; turn off the cleaning bias At the same time, turn on the driving power of the Ag target and the Ti target, adjust the power to 60W, and pre-sp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap