Method for preparing molecular sieve by utilizing potassium feldspar

A molecular sieve and potassium feldspar technology, applied in the field of molecular sieve preparation, can solve problems such as high process difficulty, poor product quality stability, and difficult to grasp the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

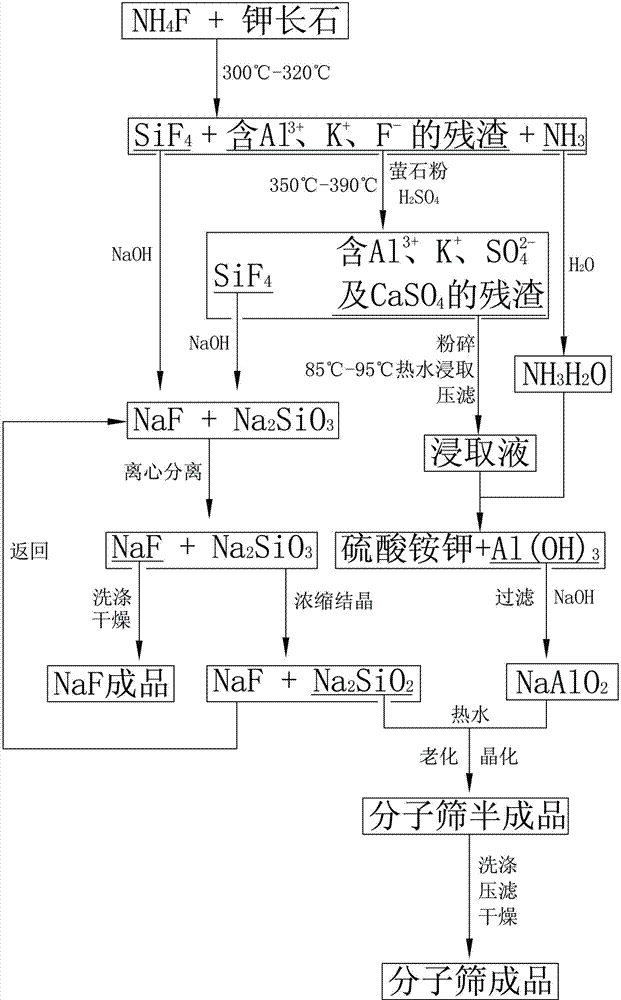

[0026] Such as figure 1 Shown, a kind of method utilizing potassium feldspar to produce molecular sieve, preparation process comprises the following steps:

[0027] Step 1: When the temperature of the converter reaches 350°C, mix 60Kg of potassium feldspar and NH 4 F (30-40) Kg is mixed evenly, and added to the converter silo in batches, and the mixing screw and star feeder are opened in turn to feed, potassium feldspar powder and NH 4 F reacts in the converter to form SiF 4 gas and containing Al 3+ 、K + and F - residue. Among them, before the reaction, potassium feldspar and NH 4 The mass ratio of F is 1:(0.4-0.6), the reaction temperature is 300°C-320°C, and the reaction time is 0.5-2 hours. After half an hour of reaction, the discharge screw is turned on, and the reacted slag is discharged from the furnace tail.

[0028] Step 2: When the temperature of the converter reaches 370°C, add fluorite powder, open the sulfuric acid feeding ball valve two minutes after the f...

Embodiment 2

[0037] The difference between Example 2 and Example 1 is that the purification in step 4 includes successive centrifugation and concentrated crystallization.

[0038] The centrifugal separation is in a three-leg centrifuge from Na 2 SiO 3 Part of the NaF crystal is separated from the solution, and then the separated NaF crystal is washed and dried to obtain a finished NaF crystal. The finished NaF crystal is an important raw material for industrial products, which improves the economic benefits generated by the decomposition of potassium feldspar.

[0039] The condensed crystal is obtained from the centrifuged Na 2 SiO 3 The NaF crystal crude product is separated from the solution. Since the concentrated and crystallized NaF crystal crude product is not as pure as the centrifuged NaF crystal finished product, the NaF crystal crude product is re-added to the product of step 3, and participates in step 4 again. ; Na through the concentrated crystallization 2 SiO 3 The solu...

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 2 is that the product in step 1 also includes ammonia gas, which is absorbed by cold water to form ammonia water, which is used to participate in the reaction in step 6. After centrifugation, the NaF crystals washed in water contain NaF, which can be used to prepare NaOH solution, and the NaOH solution can be used to participate in the reactions of step 3 and step 7. It can be seen from the above two points that the present invention recycles waste gas and waste water, participates in the production process, and improves the utilization rate of products in the potassium feldspar decomposition process while saving energy and reducing emissions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com