Polymer-ionic liquid compounded clay stabilizer and synthesis method thereof

A technology of composite clay and synthesis method, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of reducing the relative permeability of oil and gas phase, cannot produce multi-point adsorption, cannot be widely used, etc., and achieves inhibition of hydration. Swelling, good viscosity retention, water solubility enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF 4 Synthesis

[0021] (1) Add 0.03g DMAAPA, 6.97g AM, and 3.00g AA into a 250mL three-necked flask to form an aqueous solution with a total mass concentration of monomers of 20%, adjust the pH to 7 with NaOH (2M), and inject N 2 20min; Add initiator ammonium persulfate-sodium bisulfite then, its mol ratio is 1:1, and initiator add-on is 0.3% of total monomer mass, continues to pass into N 2 10-20min, and react at a temperature of 45°C for 8h; finally wash three times with absolute ethanol, pulverize, and dry to obtain the ternary polymer AA / AM / DMAAPA.

[0022](2) Get newly steamed 1-methylimidazole and bromoethane each 0.05mol to be dissolved in 50mL n-heptane, join in the three-necked flask successively, under N 2 Under a protective atmosphere, heat to 80°C and stir to reflux. After 18 hours, remove the reaction device and cool to room temperature. The light yellow viscous liquid in the lower layer was tak...

Embodiment 2

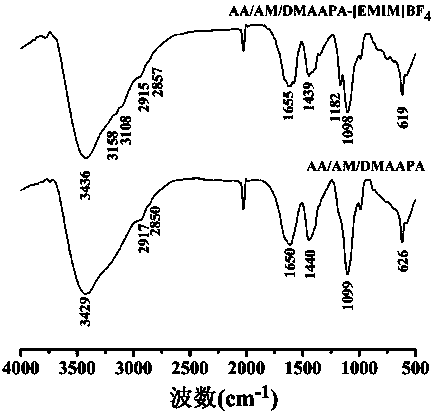

[0024] Example 2: Polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF 4 Infrared Spectroscopy Characterization of

[0025] The polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF synthesized by Example 1 4 The infrared spectrum is shown in 1. Comparison of polymer AA / AM / DMAAPA and polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF from the figure 4 , it can be seen that at 3300cm -1 There are strong amino stretching vibration absorption peaks on the left and right, 2915cm -1 、2850cm -1 There are vibration absorption peaks of methylene on the left and right, 1650cm -1 Left and right are the absorption peaks of carbonyl, 1100cm -1 is the stretching vibration absorption peak of the phosphorus-oxygen double bond; but by comparison, it can be seen that the polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF 4 at 3158cm -1 、3108cm -1 Double peaks appear at , which is caused by the stretching vibration absorption of the ethyl group on the imidazole ring, 1182cm -1 is the absor...

Embodiment 3

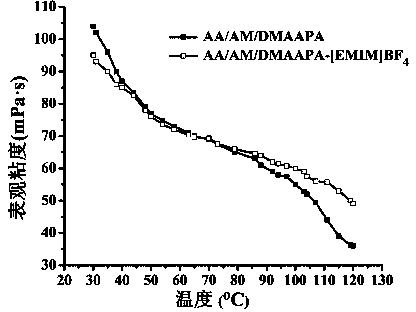

[0026] Example 3: Polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF 4 Temperature resistance investigation

[0027] The temperature resistance of the samples synthesized in Example 1 was investigated. The prepared polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF 4 Prepare an aqueous solution of 1100 mg / L, measure the apparent viscosity change of the polymer aqueous solution at a temperature of 30-120 °C, and compare it with the aqueous solution of the terpolymer AA / AM / DMAAPA with a mass concentration of 1000 mg / L. The data Such as figure 2 shown. From figure 2 It can be found that the apparent viscosity of the polymer-ionic liquid complex aqueous solution and the terpolymer aqueous solution gradually decreases with the increase of temperature. When the temperature increased to 120 °C, the polymer-ionic liquid complex AA / AM / DMAAPA-[EMIM]BF 4 The apparent viscosity of the terpolymer AA / AM / DMAAPA is 36.1mPa·s, and the viscosity retention rate reaches 51.8%, and the vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com