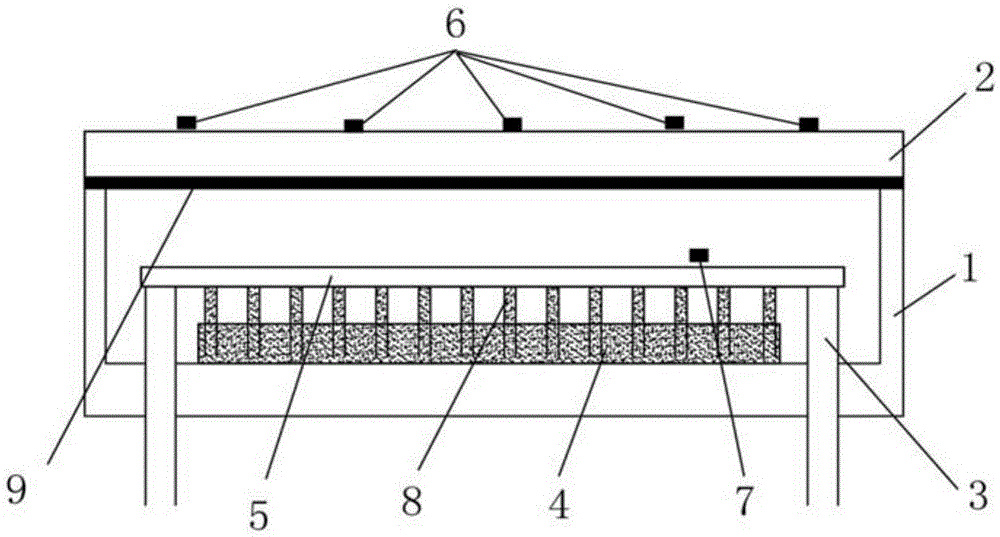

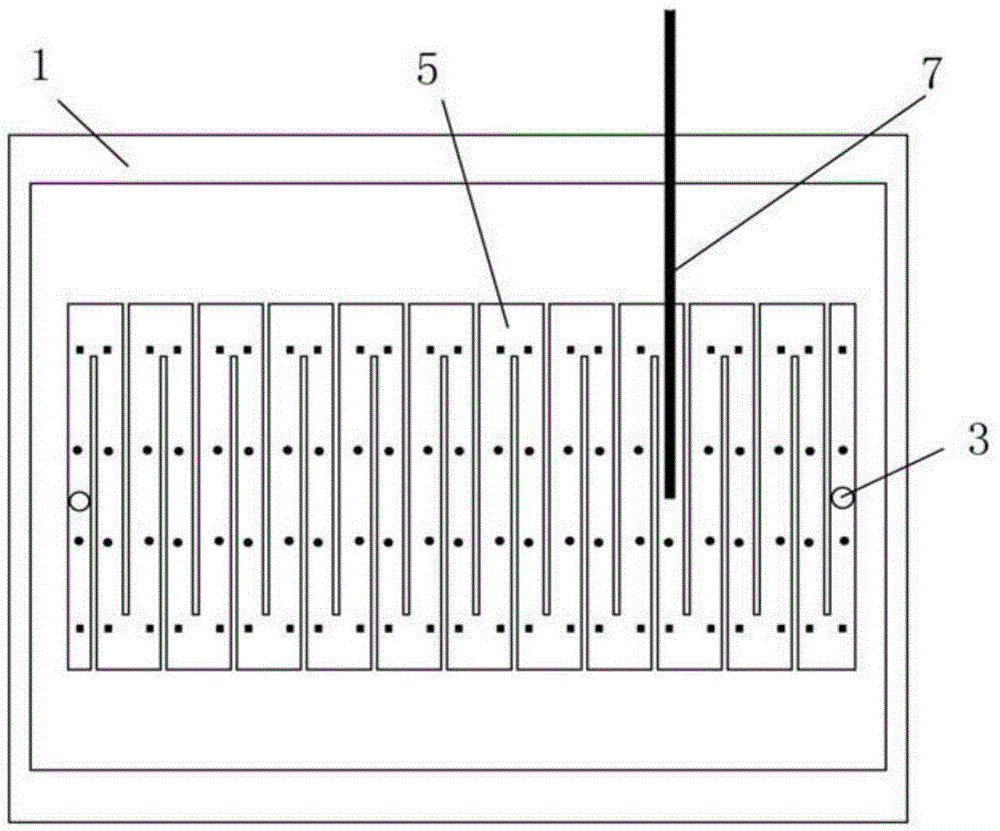

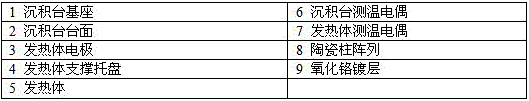

A high-temperature heating deposition platform for chemical vapor deposition

A technology of chemical vapor deposition and high-temperature heating, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of unsatisfactory stability, and achieve the characteristics of not easy to oxidize and corrode, rapid temperature rise, and uniform heating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Silicon nitride thin films were grown on flat glass substrates using chemical vapor deposition (CVD). The flat glass substrate is placed on the high-temperature heating deposition table, the heater electrode is turned on, and the substrate is heated to 700°C and maintained. Ammonia gas and silane gas are fed in at a ratio of 15:1 to grow a silicon nitride film. After working for 100 hours, the temperature of the nickel-chromium alloy heating body measured by the thermocouple of the heating element is less than 900°C.

Embodiment 2

[0041]Boron-doped carbon coatings were grown on iron substrates using chemical vapor deposition (CVD). The iron substrate is placed on the high-temperature heating deposition table, the heating element electrode is turned on, and the substrate is heated to 1000°C and maintained. Boron trichloride, methane and hydrogen are passed in at a ratio of 1:2:30 to grow a boron-doped carbon coating. After working for 100 hours, the temperature of the nickel-chromium alloy heating body measured by the thermocouple of the heating element is less than 1150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com