A kind of preparation method of bczt-based lead-free piezoelectric ceramics

A technology based on lead-free piezoelectric and ceramics, applied in the direction of piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of unstable work, lower Curie temperature of the system, health and survival Environmental hazards and other issues, to achieve the effect of low reactivity, not easy to oxidize and corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

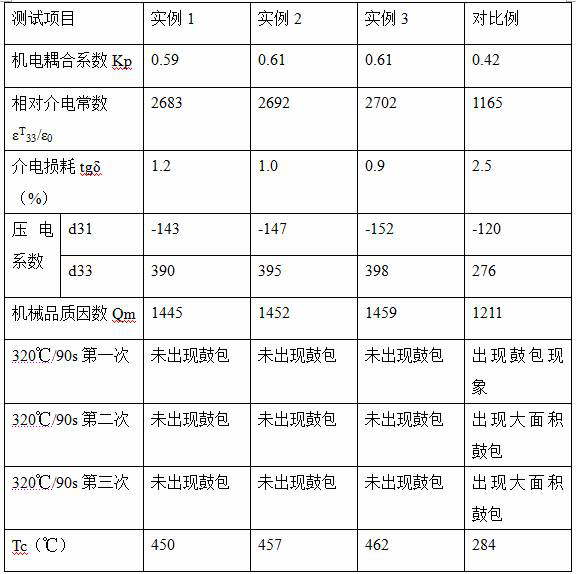

Image

Examples

Embodiment Construction

[0024]According to the weight of the weight, 3 to 4 copies of citric acid were dissolved in 10 to 12 parts of ethylene glycol, heated to 80 to 90 ° C, resulting in a mixture, and then 0.5 ~ 1.0 parts of titanate titanate 5 ~ After dilution of waterless ethanol, the mixture was stirred and stirred for 2.0 to 2.5 h, and the composite liquid was obtained, and the composite liquid was cooled to 40 to 50 ° C, and 13 to 15 parts by mass of mass fraction was continued to 25%. The strontium acetate solution, stirring reaction to 1.0 to 1.5 h, sequentially added 3 to 4 parts of mass fraction of 10% nitrate solution, 0.5 ~ 0.8 parts mass fraction of 20% nitrate solution, mix and mix the BCZT-based polymer The body; in a blast dryer of the BCZT-based polymer is placed in a blast dryer set at a set temperature of 100 to 120 ° C, drying 7 to 8 h to obtain BCZT-based gel, a BCZT in a muffle in a temperature of 450 to 500 ° C The base gel coking treatment is 4 to 5 hours to obtain a black foam, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com