Reserve sow mixed feed capable of increasing production performance of sow and preparation method

A technology for production performance and gilts, applied in animal feed, animal feed, applications, etc., can solve problems affecting the potential of gilts, obesity of gilts, abnormal estrus, etc., and achieve increased hypothalamus-pituitary-ovary Luteinizing function, reducing the incidence of constipation, and increasing the number of live litters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

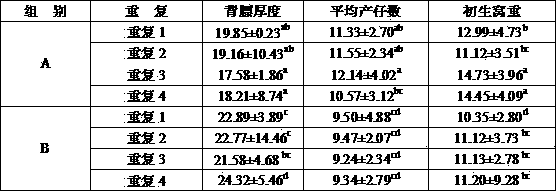

Image

Examples

Embodiment 1

[0040] 650 parts of corn, 165 parts of dehulled soybean meal, 20 parts of imported steam white fish meal, 15 parts of puffed soybean meal, 20 parts of fermented soybean meal, 40 parts of sub-meal, 30 parts of imported DDGS, 6 parts of first grade soybean oil, 10 parts of stone powder, calcium hydrogen phosphate 14 parts, 4 parts salt, 1 part baking soda, 4 parts coated sustained-release acidulant, 1 part L-lysine hydrochloride, 0.5 part DL-methionine, 0.6 part L-threonine, 35% mass concentration 0.2 parts of xylo-oligosaccharides, 1 part of sodium glutamate, 1 part of Scutellaria baicalensis, 1 part of Cuscuta, 3.5 parts of Pulsatilla, 1 part of Coptis, 2 parts of Phellodendron chinense, 3.5 parts of Qin bark, 1 part of choline chloride with a mass concentration of 60% , 5000U / g high temperature resistant phytase 0.4 parts, compound enzyme (trade name Saihesu) 0.2 parts, mold release agent 0.5 parts, gilt composite premix 5 parts.

[0041] The sow composite premix contains VA3000...

Embodiment 2

[0056] 640 parts of corn, 160 parts of dehulled soybean meal, 20 parts of imported steam white fish meal, 25 parts of puffed soybean meal, 20 parts of fermented soybean meal, 40 parts of sub-meal, 31 parts of imported DDGS, 8 parts of first-grade soybean oil, 10.5 parts of stone powder, hydrogen phosphate 13.4 parts of calcium, 4.2 parts of salt, 1 part of baking soda, 4 parts of coated sustained-release acidulant, 2 parts of L-lysine hydrochloride, 0.5 parts of DL-methionine, 0.6 parts of L-threonine, 35 parts by mass % Xylooligosaccharides 0.2 part, sodium glutamate 1 part, Scutellaria baicalensis 1 part, Cuscuta 1 part, Pulsatilla 3.5 parts, Coptis 1 part, Phellodendron chinensis 2 parts, Qin bark 3.5 parts, 60% mass concentration of choline chloride 1 Parts, 5000U / g high temperature resistant phytase 0.4 parts, compound enzyme (trade name Saihesu) 0.2 parts, mold release agent 0.5 parts, gilt composite premix 5 parts.

[0057] The rest is implemented as in Examp...

Embodiment 3

[0059] 640 parts of corn, 165 parts of dehulled soybean meal, 19 parts of imported steam white fish meal, 23 parts of puffed soybean meal, 21 parts of fermented soybean meal, 38 parts of sub-meal, 30-35 parts of imported DDGS, 8 parts of first-grade soybean oil, 10.5 parts of stone powder, phosphoric acid 14.7 parts of calcium hydrogen, 4.5 parts of table salt, 1 part of baking soda, 4 parts of coated sustained-release acidulant, 1.3 parts of L-lysine hydrochloride, 0.3 parts of DL-methionine, 0.6 parts of L-threonine, mass concentration 0.22 parts of 35% xylo-oligosaccharides, 1 part of sodium glutamate, 1 part of Scutellaria baicalensis, 1 part of Cuscuta, 3.5 parts of Pulsatilla, 1 part of Coptis, 2 parts of Phellodendron chinense, 3.5 parts of Qin Bark, 60% of Choline Chloride 1 part, 5000U / g high temperature resistant phytase 0.4 part, compound enzyme (trade name Saihesu) 0.1 part, mold release agent 0.5 part, gilt compound premix 5 parts.

[0060] The rest is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com