Preparation method of tissue suitable type composite material dental implant

A dental implant and composite material technology, applied in the field of biomedical composite material preparation, to achieve high biological activity, firm tissue integration, and short implant healing period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a tissue-compatible composite dental implant, comprising the following steps:

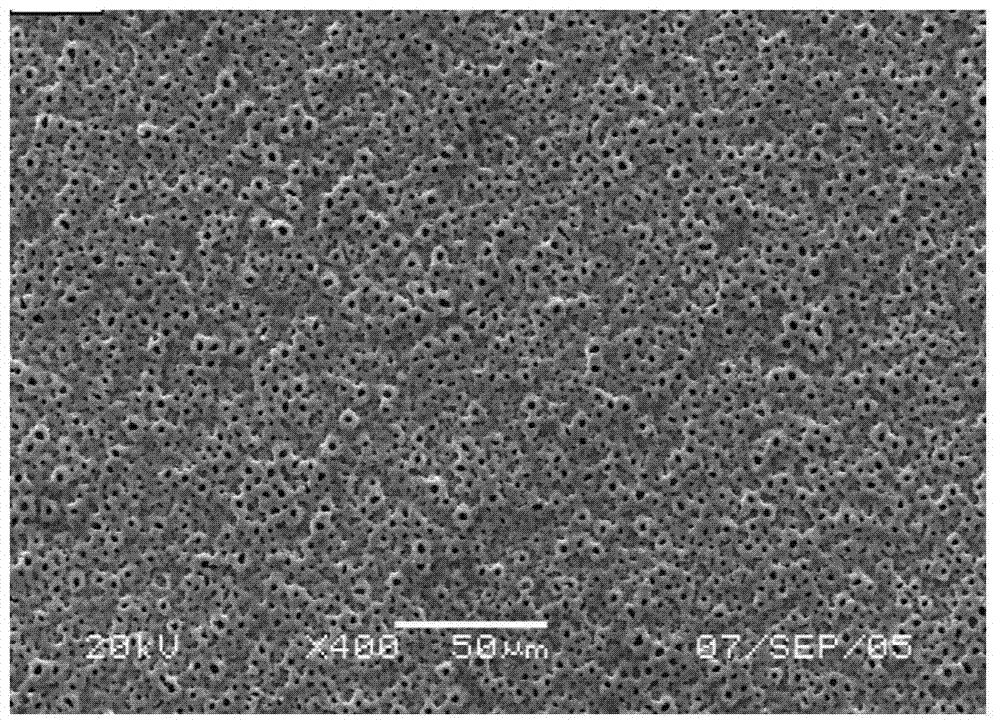

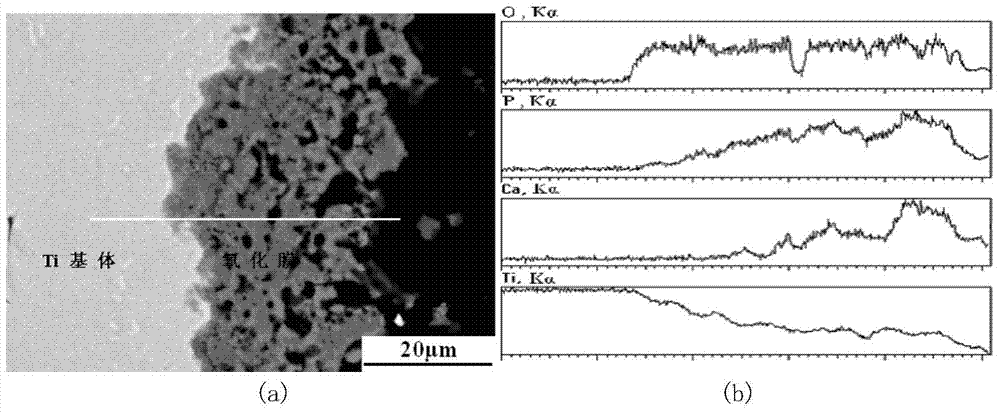

[0027] (1) Perform micro-arc oxidation treatment on the surface of titanium or titanium alloy implants in contact with bone tissue, and perform micro-arc oxidation in a calcium-phosphorus electrolyte with a mass ratio of calcium and phosphorus of Ca / P=5. Time T=15min, electrode voltage U=450V, electrode frequency f=600Hz, a layer of calcium and phosphorus-containing porous composite ceramic membrane with biological activity is formed;

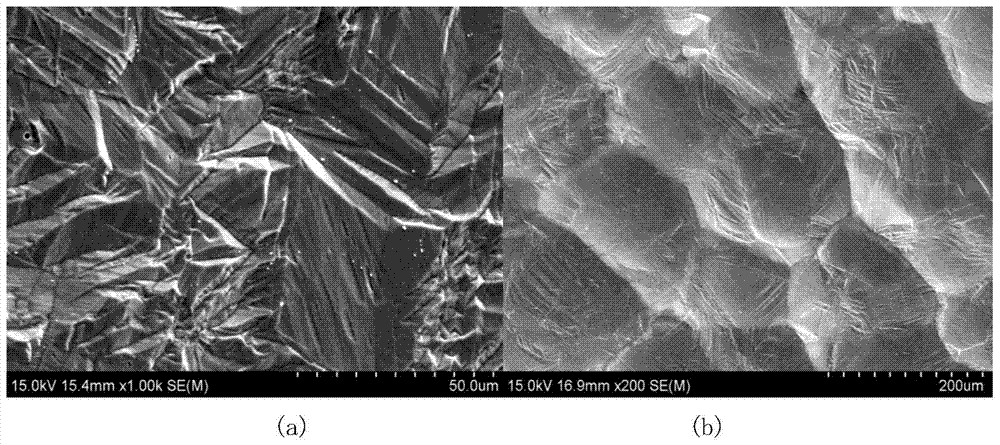

[0028] (2) The surface part of the implant in contact with the soft tissue was etched in a mixed etching agent composed of hydrofluoric acid and hydrochloric acid. The volume ratio of 47% HF to 38% HCl was 50:50. The etching treatment temperature is 55° C., and the etching treatment time is 5 minutes.

[0029] (3) Immerse the dental implant after micro-arc oxidation and surface etching treatment in a composite simulated body fluid cont...

Embodiment 2

[0034] A method for preparing a tissue-compatible composite dental implant, comprising the following steps:

[0035] (1) Perform micro-arc oxidation treatment on the surface part of the titanium or titanium alloy implant in contact with bone tissue, and perform micro-arc oxidation in a calcium-phosphorus electrolyte with a mass ratio of calcium and phosphorus of Ca / P=3. Time T=10min, electrode voltage U=500V, electrode frequency f=700Hz, a layer of calcium and phosphorus-containing porous composite ceramic membrane with biological activity is formed;

[0036] (2) The surface part of the implant in contact with the soft tissue was etched in a mixed etching agent composed of hydrofluoric acid and hydrochloric acid. The volume ratio of 47% HF to 38% HCl was 50:50. The etching treatment temperature is 55° C., and the etching treatment time is 8 minutes.

[0037] (3) Immerse the dental implant after micro-arc oxidation and surface etching treatment in a composite simulated body fl...

Embodiment 3

[0039] A method for preparing a tissue-compatible composite dental implant, comprising the following steps:

[0040] (1) Perform micro-arc oxidation treatment on the surface part of the titanium or titanium alloy implant in contact with bone tissue, and perform micro-arc oxidation in a calcium-phosphorus electrolyte with a mass ratio of calcium to phosphorus Ca / P=6. Time T=20min, electrode voltage U=400V, electrode frequency f=650Hz, a layer of calcium and phosphorus-containing porous composite ceramic membrane with biological activity is formed;

[0041] (2) The surface part of the implant in contact with the soft tissue was etched in a mixed etching agent composed of hydrofluoric acid and hydrochloric acid. The volume ratio of 47% HF to 38% HCl was 50:50. The etching treatment temperature is 55° C., and the etching treatment time is 10 minutes.

[0042] (3) Immerse the dental implant after micro-arc oxidation and surface etching treatment in a composite simulated body fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com