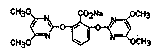

Bispyribac-sodium dispersible oil suspended agent and preparation method thereof

A bispyribac-dispersed oil technology, applied in the fields of botanical equipment and methods, herbicides, algicides, biocides, etc., can solve the problems of water suspension agent deposition, stratification, environmental and human pollution, and dust generation. , to achieve the effect of simple production equipment and methods, reducing environmental pollution and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

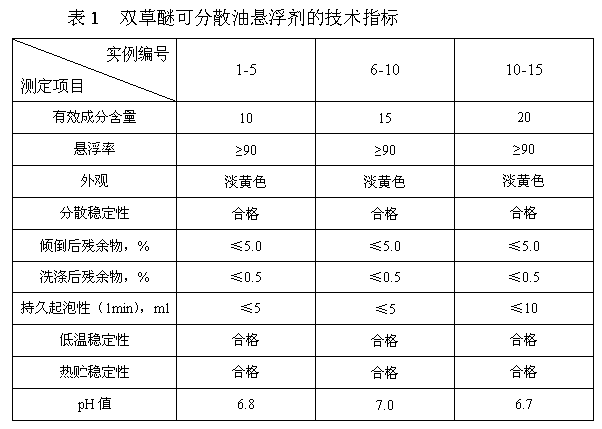

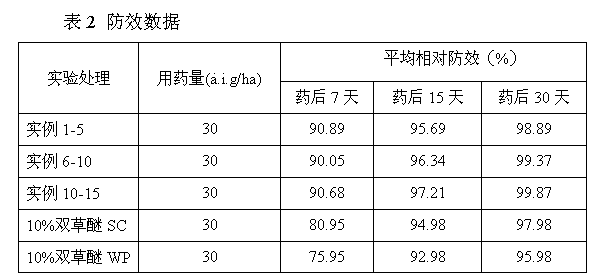

Embodiment 1

[0020] After adding 716g of methyl oleate into the shear kettle, add 20g of emulsifier alkylphenol polyoxyethylene ether, 20g of calcium dodecylbenzenesulfonate, 30g of fatty alcohol polyoxyethylene ether, dispersant wood Sodium sulfonate 3g, organic bentonite 40g, long-chain alcohol defoamer 50g and citric acid 15g, mix and stir, and add 106g of bispyribac with a purity of 95% under stirring at a speed of 1500~10000 rpm in a high-speed shearing machine After medicine, cut for 10-40 minutes, and then grind to particle size D by sand mill 90 If it is less than 8 μm, a pale yellow bispyribac-encapsulant dispersible oil suspension concentrate can be obtained.

Embodiment 2

[0022] After adding 450g of methyl oleate and 85.9g of soybean oil into the shear kettle, add 300g of emulsifier sorbitan monolaurate, 1g of wetting agent sodium alkyl succinate sulfonate, fatty alcohol sulfate 1g, 50g of dispersant naphthalenesulfonate formaldehyde condensate, 5g of xanthan gum, 0.1g of silicone defoamer and 1g of triethanolamine, mix and stir, and stir at the speed of high-speed shearing machine 1500~10000 rpm After adding 106g of bispyribac with a purity of 95%, cut it for 10-40 minutes, and then grind it with a sand mill to a particle size of D 90 If it is less than 8 μm, a pale yellow bispyribac-encapsulant dispersible oil suspension concentrate can be obtained.

Embodiment 3

[0024] After adding 450g of methyl oleate and 139g of turpentine-based vegetable oil into the shear kettle, add 200g of emulsifier alkylphenol polyoxyethylene ether sodium sulfate, 30g of wetting agent calcium dodecylbenzenesulfonate, and dispersant 40g of phenol polyoxyethylene ether phosphate, 15g of fumed silicon dioxide, 10g of polyglycerin defoamer, 10g of sodium acetate, mix and stir, and add the 95% purity biscaline under stirring at a speed of 1500~10000 rpm at a high speed shear After 106g of ether, cut for 10-40 minutes, and then grind to particle size D by sand mill 90 If it is less than 8 μm, a pale yellow bispyribac-encapsulant dispersible oil suspension concentrate can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com