Selective catalytic reduction (SCR) catalyst and preparation method thereof

A technology of SCR catalyst and oxide, which is applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problems of catalyst wear, can not meet the purification, affect the service life and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a preparation method of the above-mentioned SCR catalyst, comprising the following steps: S1) mixing the soluble silicon source and the soluble titanium source in an alcohol solvent, adding water, stirring, and standing to obtain a gel; S2) mixing the The above gel is dried and roasted to obtain TiO 2 -SiO 2 Composite oxide support; S3) Dissolve soluble metal salt and soluble cerium salt in water, then add TiO 2 -SiO 2 The composite oxide carrier is stirred until powder solid is obtained, dried and roasted to obtain an intermediate product; the corresponding metal oxide of the metal in the soluble metal salt is a solid acid; the quality of the corresponding metal oxide of the soluble metal salt is TiO 2 -SiO 2 1-10% of the mass of the composite oxide support; the corresponding CeO of the soluble cerium salt 2 mass TiO 2 -SiO 2 0% to 10% of the mass of the composite oxide carrier; S4) adding the intermediate product to a solution...

Embodiment 1

[0049] 1.1 Mix and stir 60ml absolute ethanol, 12ml butyl titanate and 12ml tetraethyl orthosilicate evenly, and then according to the ratio of the amount of butyl titanate and ethyl orthosilicate to the amount of water, Add deionized water at a ratio of 1:5, continue to stir for 5 hours, and leave to age for 48 hours to obtain a gel; dry the obtained gel in an oven at 80°C for 14 hours, and bake it in a muffle furnace at 300°C for 10 hours to obtain TiO 2 -SiO 2 Composite oxide carrier.

[0050] 1.2 Add 3.04g of ammonium metatungstate and 3.26g of cerium nitrate into 50ml of deionized water, stir for 2h, then add 20g of TiO obtained in 1.1 2 -SiO 2 The composite oxide carrier was continuously stirred at 60°C until it was dried to obtain a solid powder, which was dried in an oven at 80°C for 14 hours, calcined in a muffle furnace at 300°C for 10 hours, and ground to obtain an SCR catalyst.

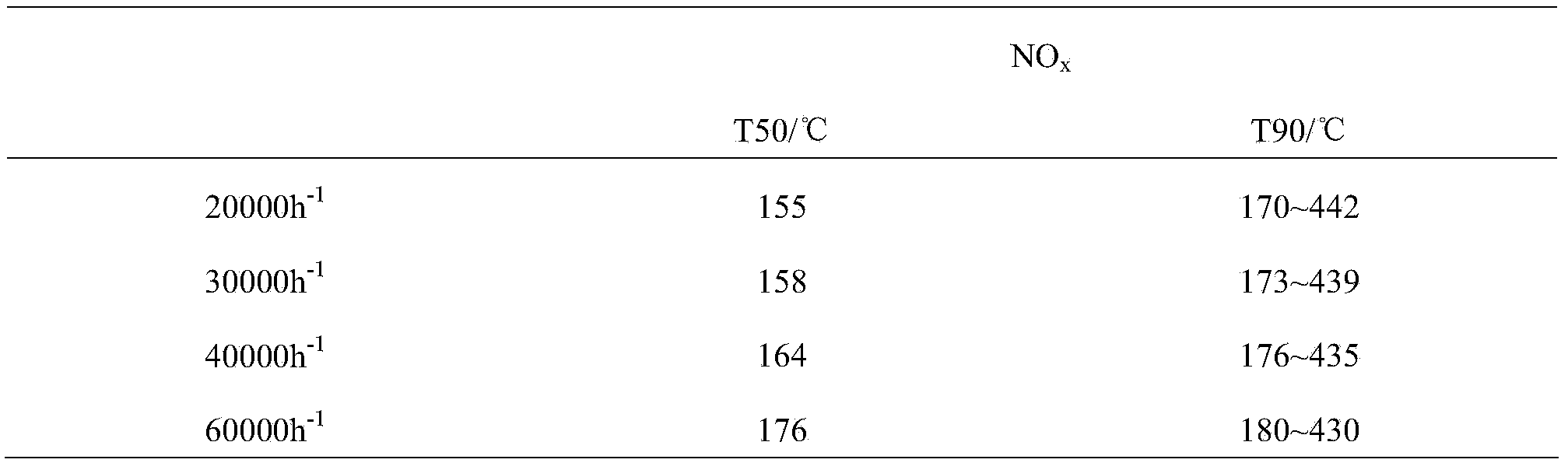

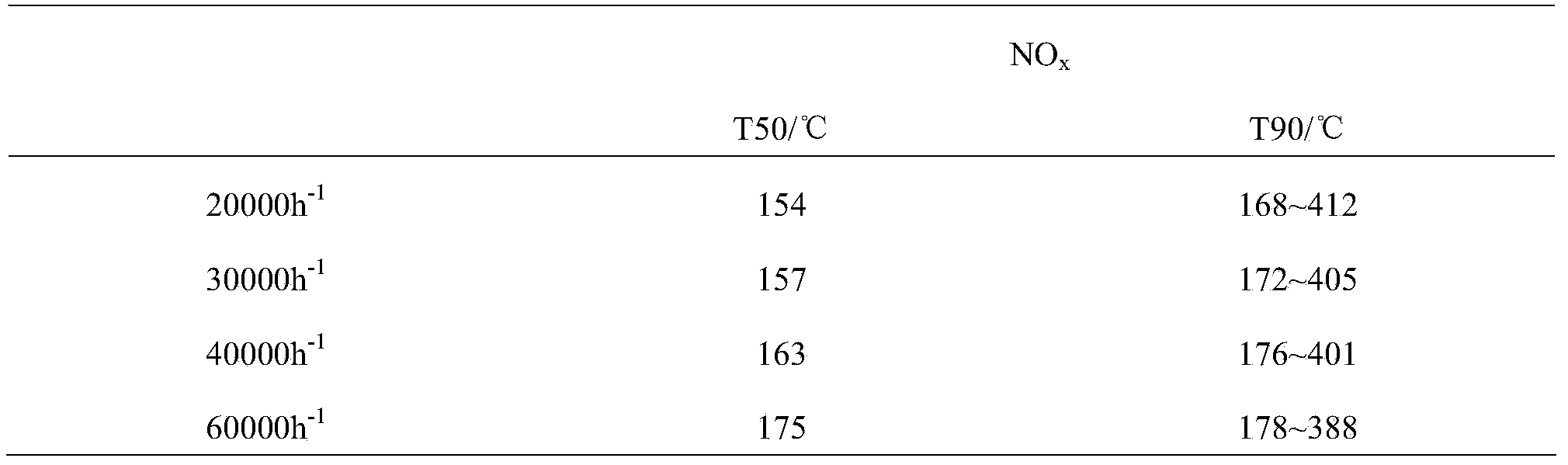

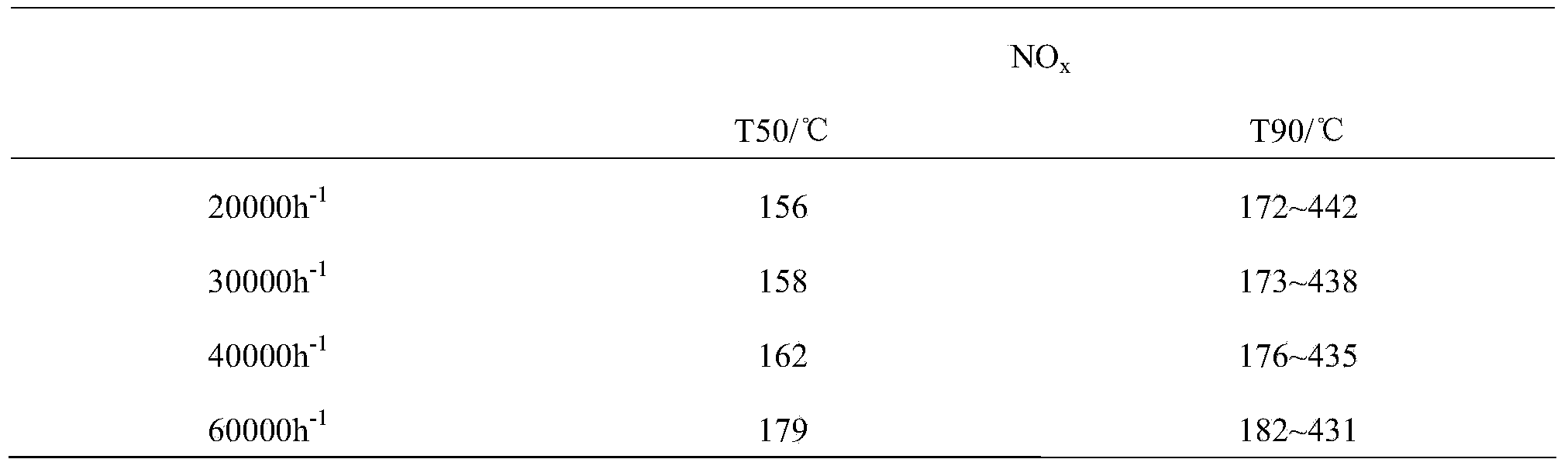

[0051] Perform a performance test on the SCR catalyst obtained in 1.2: put the SCR...

Embodiment 2

[0057] 2.1 Mix 60ml of absolute ethanol, 12ml of butyl titanate and 20ml of sodium silicate solution with a mass fraction of 60% and stir evenly, and then mix and mix according to the amount of butyl titanate and tetraethyl orthosilicate and the substance of water Add deionized water at a ratio of 1:5, continue to stir for 5 hours, and leave to age for 48 hours to obtain a gel; dry the obtained gel in an oven at 150°C for 8 hours, and dry it in a muffle furnace for 700 ℃ roasting for 2h to get TiO 2 -SiO 2 Composite oxide carrier.

[0058] 2.2 Add 3.04g of niobium oxalate into 50ml of deionized water, stir for 2h, then add 20g of TiO obtained in 2.1 2 -SiO 2 The composite oxide carrier was continuously stirred at 60°C until it was dried to obtain a powder solid, which was dried in an oven at 150°C for 8 hours, and calcined in a muffle furnace at 700°C for 2 hours to obtain an intermediate product.

[0059] 2.3 will be 1.05gV 2 o 5 Dissolve the powder in 10ml of oxalic ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com