Production method of organic fertilizer with cow dung as main material

A manufacturing method and technology of organic fertilizer, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of poor aggregate structure, large demand for chicken manure, high potassium content, etc., to reduce the probability of infection, simple proportioning, and absorption high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

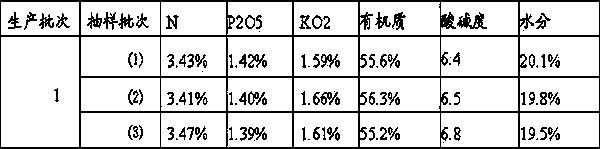

[0028] Example 1,

[0029] 100 parts of a mixture of cow dung and sawdust, including 20 parts of cow dung, 80 parts of sawdust; 15 parts of animal offal powder, 15 parts of plant ash, 0.5 parts of humic acid, 5 parts of phosphate rock powder, 12 parts of rice husk, and 6 parts of seaweed powder , 6 parts of shell powder, 8 parts of perlite, 2 parts of antiseptic, 8 parts of Kochia scoparia, 10 parts of pine needles, 12 parts of Tripterygium wilfordii, 8 parts of basil, 8 parts of cinnamon, 12 parts of cloves, 12 parts of garlic powder, 40 parts of bentonite.

[0030] during preparation

[0031] A. Fermentation raw materials: the mixture of cow dung and sawdust, animal viscera powder, plant ash, humic acid, phosphate rock powder, rice husk, seaweed powder, shell powder, perlite, stir evenly, pile up in the fertilizer tank, add decay promoting After stirring, ferment for 2-3 days, use a turning and throwing machine to repeatedly turn and throw the fermented raw materials in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| fiber elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com