Supported type Au catalyst containing organic polymer electronic auxiliary

A supported catalyst technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, dispersed particle separation, etc., can solve problems such as easy deactivation, low selectivity, and poor stability , to achieve the effect of adsorption and activation promotion, lower reaction temperature and promotion of catalytic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

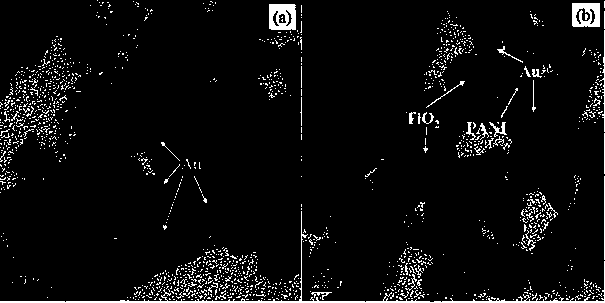

[0031] Au / TiO 2 -Preparation of PANI catalyst

[0032] Dry titanium gel (patent number: 98115808.0) at 80°C, heat-treat the obtained solid gel at 450°C for about 3 h, grind and sieve to obtain TiO 2 carrier. Weigh 2 g TiO 2 (The particle size is 60-80 mesh) and 50 μL of aniline were added to 80 mL of 1 mol / L HCl solution, and stirred at room temperature for 30 min. Then 10 mL of an aqueous solution containing 2.45 g of ammonium persulfate was added dropwise to the above solution under magnetic stirring, and the resulting suspension was stirred and reacted for 5 hours, filtered, and washed with distilled water to remove excess ions attached to the precipitate. Dry the obtained precipitate at room temperature at 80°C to obtain TiO 2 - PANI(50) vector. According to the above steps, by changing the concentration of aniline solution, TiO 2 –PANI(100) and TiO 2 - PANI (200) vector.

[0033] Mix the carrier prepared above with 2 mL of HAuCl containing Au at a concentration of...

Embodiment 2

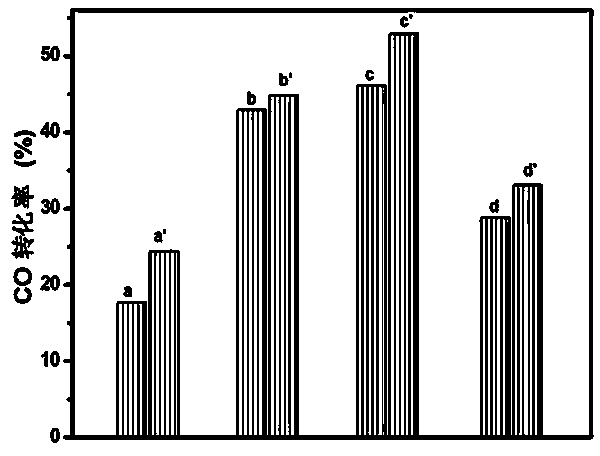

[0035] Catalyst Performance Evaluation

[0036] The performance evaluation of the catalyst prepared in Example 1 for catalytic oxidation of CO was carried out on a self-designed atmospheric pressure continuous flow reaction device with circulating condensed water. About 0.5 g of catalyst is packed in a quartz plate reactor (length 30mm*width 15mm*height 1mm), the catalyst particle size is about 0.2~0.3 mm (60~80 mesh), CO and O in the reaction gas 2 The contents of He were fixed at 0.3 V% and 0.3 V%, respectively, He gas was used as the balance supplementary gas, and the total flow rate of the reaction gas was about 100 mL / min. The reaction temperature is controlled at 25°C by circulating condensed water (with thermocouple detection). Agilent 7890D gas chromatograph was used to regularly analyze CO and O in the atmosphere 2 and CO 2 concentration, the detector is TCD, the packed column is TDX-01, and the result of reaction for 6 hours is used to calculate the CO conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com