Urea synergist and preparation method thereof

A technology of synergist and urea, which is applied in the field of urea synergist and its preparation, can solve the problems of low utilization rate of urea nitrogen, increase planting cost, affect crop growth, etc., so as to promote rapid growth, reduce planting cost, improve Effects of Fertilizer Efficiency and Nitrogen Use Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

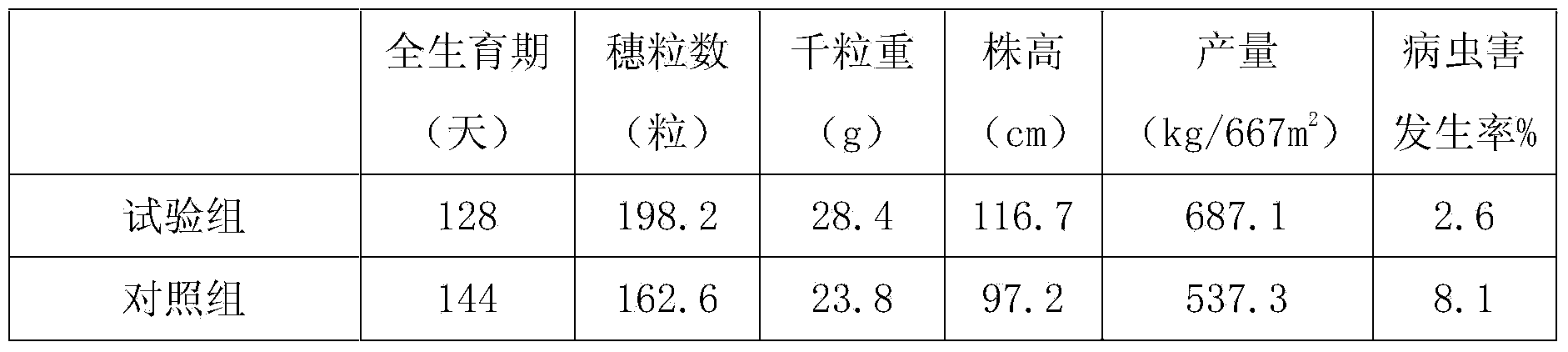

Examples

Embodiment Construction

[0011] A urea synergist, made of the following raw materials by weight (kg): 160 ammonium sulfate, 160 potassium dihydrogen phosphate, 10 ammonium molybdate, 30 boric acid, 10 cobaltous chloride, 10 nickel sulfate, ethylenediaminetetra Disodium acetate 30, zinc sulfate 40, enteromorpha dry powder 25, potassium fulvic acid 10, volcanic ash 20, tea dry powder 15, modified zeolite powder 70, sodium nitrophenolate 5;

[0012] The preparation method of the modified zeolite powder is as follows: (a) Take the zeolite and place it at 660°C for calcination for 3 hours, after cooling to room temperature, put it in a hydrochloric acid solution with a concentration of 15% and boil for 20 minutes, filter, and use distilled water to filter the residue Wash, dry, crush, and pass through a 150-mesh sieve; (b) add 4% tobacco powder, 2% neem bark powder, 1% basil leaf powder, 3 tung tree shell powder and 3% pomegranate peel powder, mixed evenly, and then beaten with water to make a slurry with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com