Preparation method of NbSe2/CeNbO4 nanocomposite

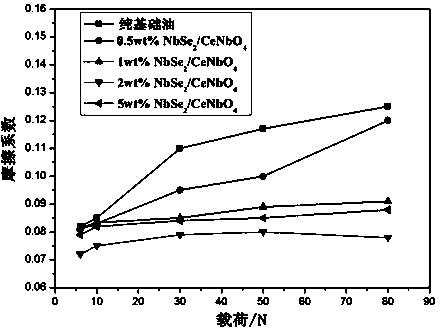

A technology of nanocomposite materials and raw materials, applied in the field of preparation of NbSe2/CeNbO4 nanocomposite materials, can solve the problems of no nanocomposite materials, high friction coefficient, small adhesion coefficient, etc., and achieve simple preparation process, low cost, good friction and wear performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

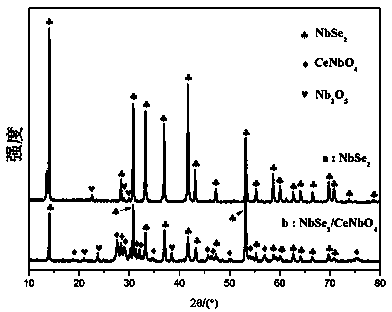

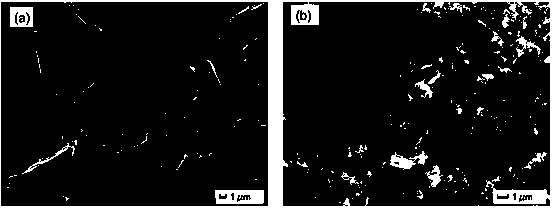

[0027] Weigh 9.29g of Nb powder and 18.15g of Se powder respectively, and take 274 g of stainless steel balls with diameters of 5mm and 8mm according to the mass ratio of balls and materials of 10:1 (the number ratio of 5mm and 8mm stainless steel balls is 3: 1); The weighed Nb powder, Se powder and stainless steel balls were mixed and put into a ball mill jar for wet alcohol milling at a speed of 200 rpm for 9 h; °C; put the dried sediment into a sealed quartz glass tube; put the quartz glass tube into a tube furnace and heat it to 800 °C with a heating rate of 10 °C / min, keep it warm for 1 hour and then cool it down to room temperature naturally with the furnace , that is, pure NbSe 2 powder.

Embodiment 2

[0029] Weigh 9.29g of Nb powder, 18.15g of Se powder, CeO 2 Powder 0.823g, take 283 g of stainless steel balls with diameters of 5mm and 8mm according to the mass ratio of ball to material 10: 1 (the number ratio of 5mm and 8mm stainless steel balls is 3: 1); the weighed elemental Nb powder and elemental Se powder and rare earth CeO 2 The powder and stainless steel balls were put into the ball mill jar together for alcohol wet milling, and the QMISP2 ball mill was used for ball milling at a speed of 200rpm for 9 hours; after the ball milling was completed, the sediment was put into an oven for drying at 80°C; Put the dried sediment into a φ8mm×10mm quartz glass tube with one end open, then heat it with an acetylene flame to elongate the open end to form a thin opening, pump out the air and fill it with Ar gas for protection, and then melt and seal the tube mouth; Put the quartz glass tube into a tubular reactor and heat it up to 600°C with a heating rate of 10°C / min. After h...

Embodiment 3

[0031] Weigh respectively Nb powder 9.29g, Se powder 18.15g, CeO 2Powder 1.372g, take 283 g of stainless steel balls with diameters of 5mm and 8mm according to the mass ratio of ball to material 10: 1 (the number ratio of 5mm and 8mm stainless steel balls is 3: 1); the weighed elemental Nb powder and elemental Se powder and rare earth CeO 2 The powder and stainless steel balls were put into the ball mill jar together for alcohol wet milling, and the QMISP2 ball mill was used for ball milling at a speed of 200rpm for 9 hours; after the ball milling was completed, the sediment was put into an oven for drying at 80°C; Put the dried sediment into a φ8mm×10mm quartz glass tube with one end open, then heat the open end with an acetylene flame to form a thin opening, pump out the air and fill it with Ar gas for protection, and then melt and seal the tube mouth; Put the quartz glass tube into a tubular reactor and heat it up to 600°C with a heating rate of 10°C / min. After holding for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com