Preparation method of macromolecule activated carbon composite filler

A technology of composite packing and manufacturing method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems that the type and quantity cannot be artificially controlled, the thickness of the packing layer is limited, and the resistance of the gas tower increases. Conducive to attachment and growth, improved processing capacity, and low mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

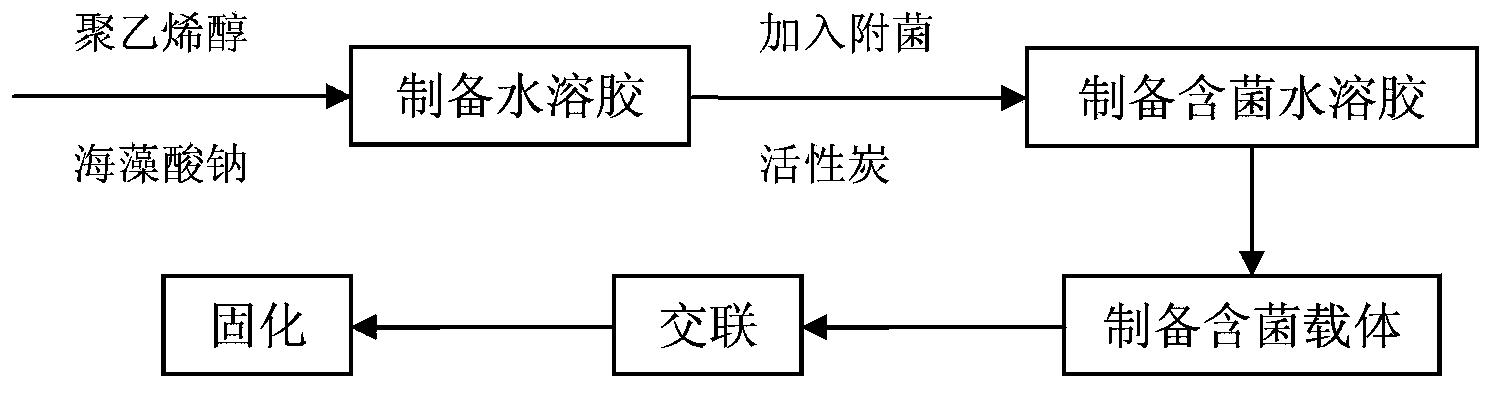

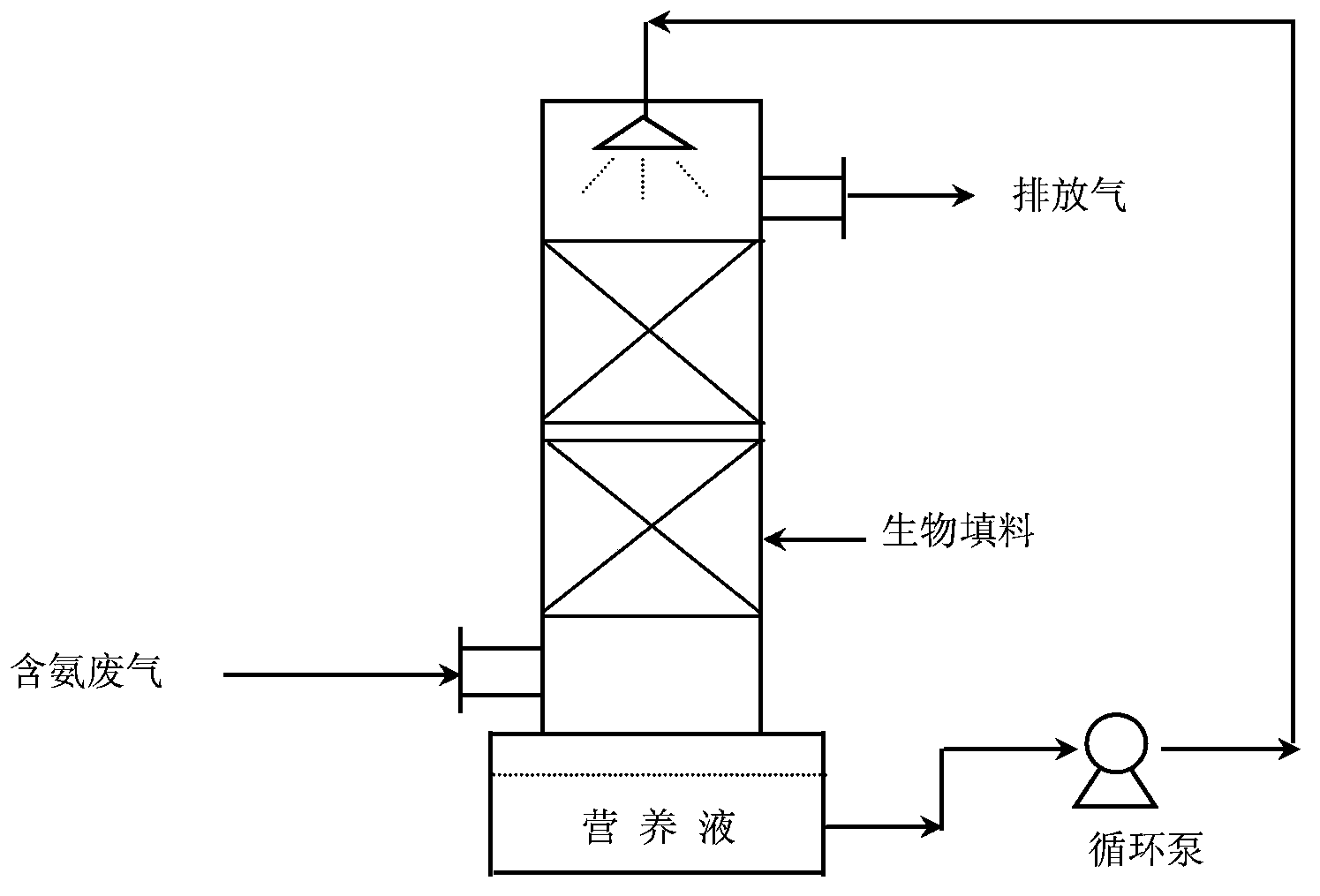

[0026] The biological filler of the invention is used to immobilize nitrifying bacteria for treating ammonia-containing waste gas.

[0027] Immobilized cell gel composition, by weight percentage:

[0028] Polyvinyl alcohol 7.5%

[0029] Sodium Alginate 1.5%

[0030] Made into mixed hydrosol;

[0031] According to 30% of activated carbon powder attached to microorganisms, add it to the mixed hydrosol to make a bacteria-containing hydrosol glue;

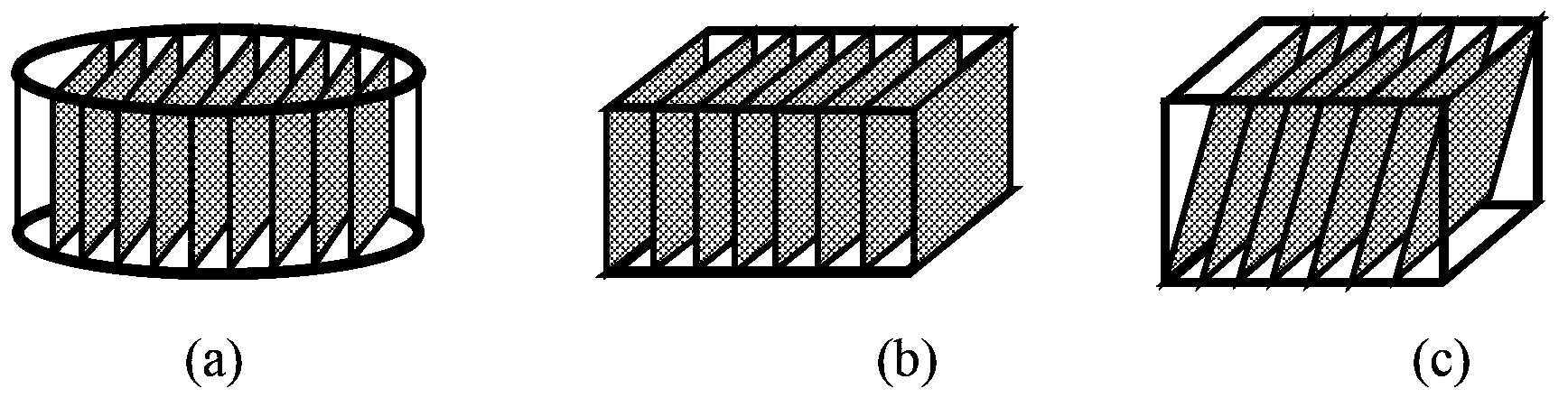

[0032] The packing frame is made of stainless steel plate and stainless steel wire. Its appearance is a cylinder with a height of 100mm and a diameter of 150mm. The mesh fabric is nylon mesh with an aperture of 0.5×0.3mm. The distance between two pieces of mesh is 5-15mm.

[0033] The packing frame with the fixed mesh is leached several times in the uniformly mixed bacteria-containing hydrosol glue, so that the glue can be evenly covered on the mesh, and then the glue containing 1.5% CaCl 2 Soak in saturated boric acid solution for...

Embodiment 2

[0039] Immobilized cell gel composition:

[0040] 10% of polyvinyl alcohol

[0041] Sodium Alginate 1.8%

[0042] 15% activated carbon powder attached to microorganisms

[0043] All the other conditions are with embodiment 1. Table 2 shows the effect of using the biological filler of this embodiment to immobilize nitrifying bacteria to treat ammonia-containing waste gas.

[0044] Table 2

[0045]

Embodiment 3

[0047] Immobilized cell gel composition:

[0048] Polyvinyl alcohol 3%

[0049] Sodium alginate 0.3%

[0050] 6.25% powdered activated carbon attached to microorganisms

[0051] Other conditions are the same as in Example 1, and the effect of using the biological filler of this example to immobilize nitrifying bacteria to treat ammonia-containing waste gas is shown in Table 3.

[0052] table 3

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesh aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com