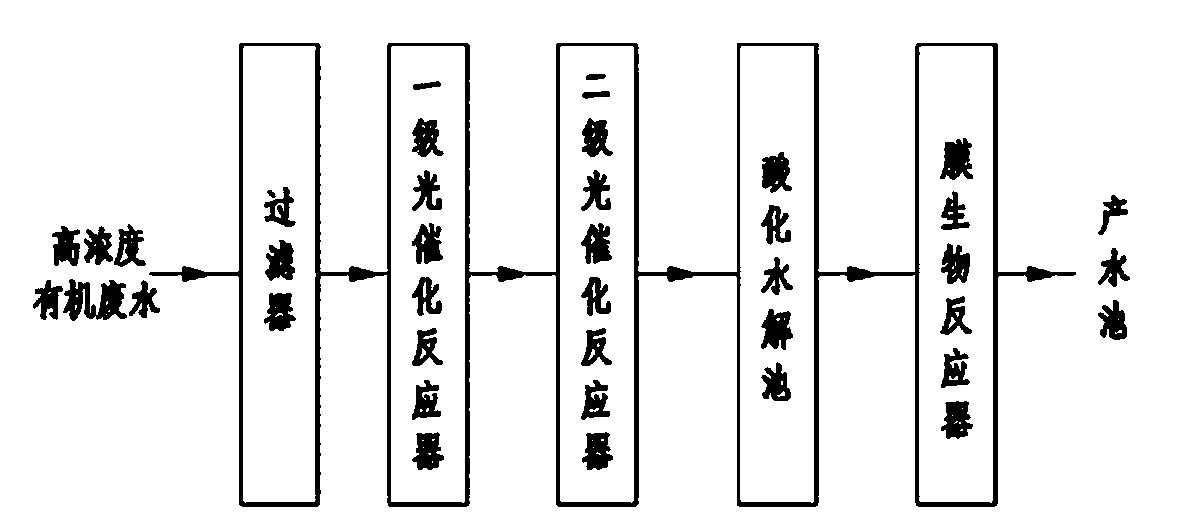

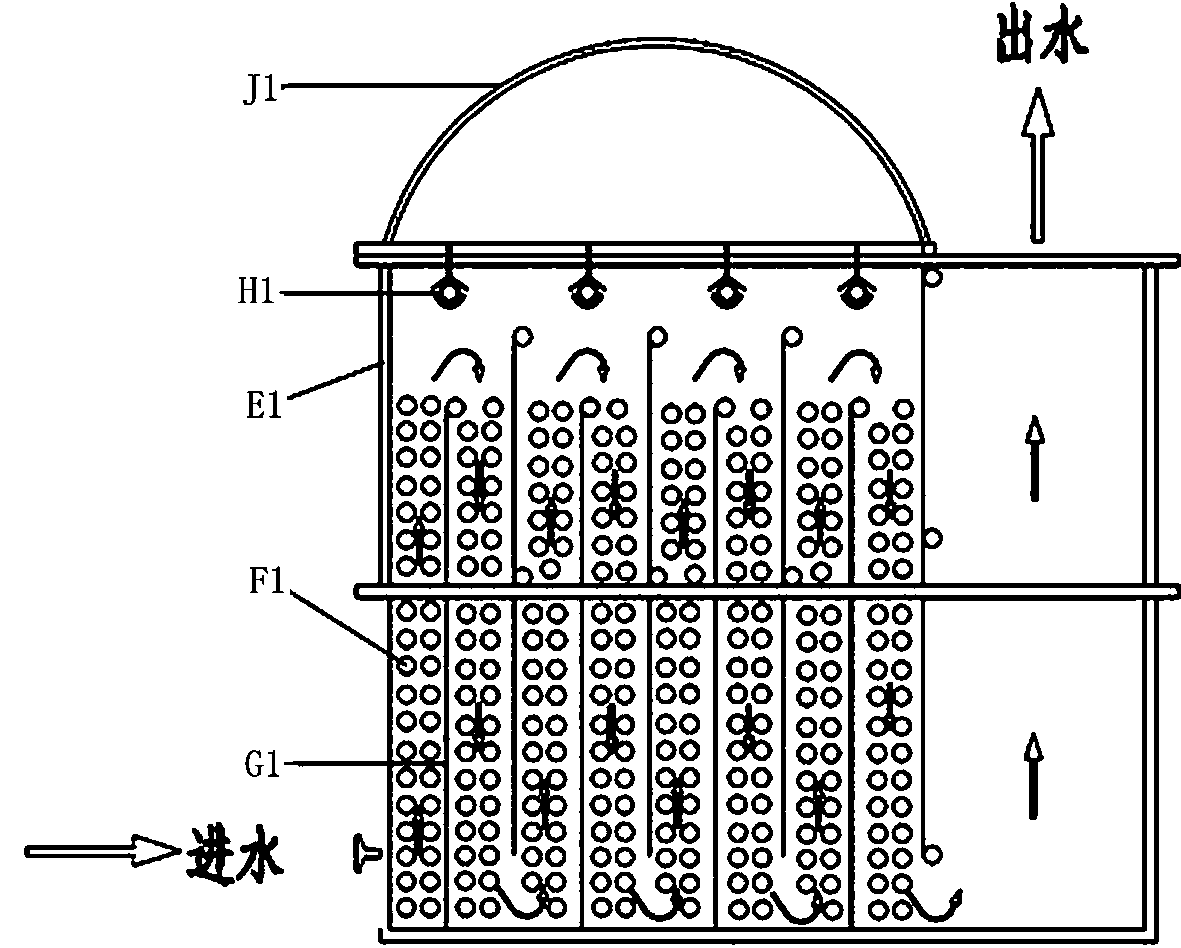

Device and method for treating high density organic waste water by multiphase photocatalysis combined film bioreactor

A membrane bioreactor, bioreactor technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high treatment cost, achieve low operating cost, application Wide range and small equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] A certain liquid crystal production wastewater contains various organic molecules such as tetrahydrofuran, ethanol, dichloroethane, petroleum ether, and glacial acetic acid. The molecular structure is relatively stable, and it is a kind of high-concentration organic wastewater that is difficult to degrade. The water quality and quantity are as follows:

[0046] Production wastewater volume: 40m 3 / h.

[0047] Waste water quality: COD=10000mg / L, BOD 5 =3000mg / L, PH=6~8, main organic content fraction (mass): tetrahydrofuran 6.67%, ethanol 1.21%, dichloromethane 0.09%, petroleum ether 0.02%, 1,4 hydroquinone 0.01%, etc.

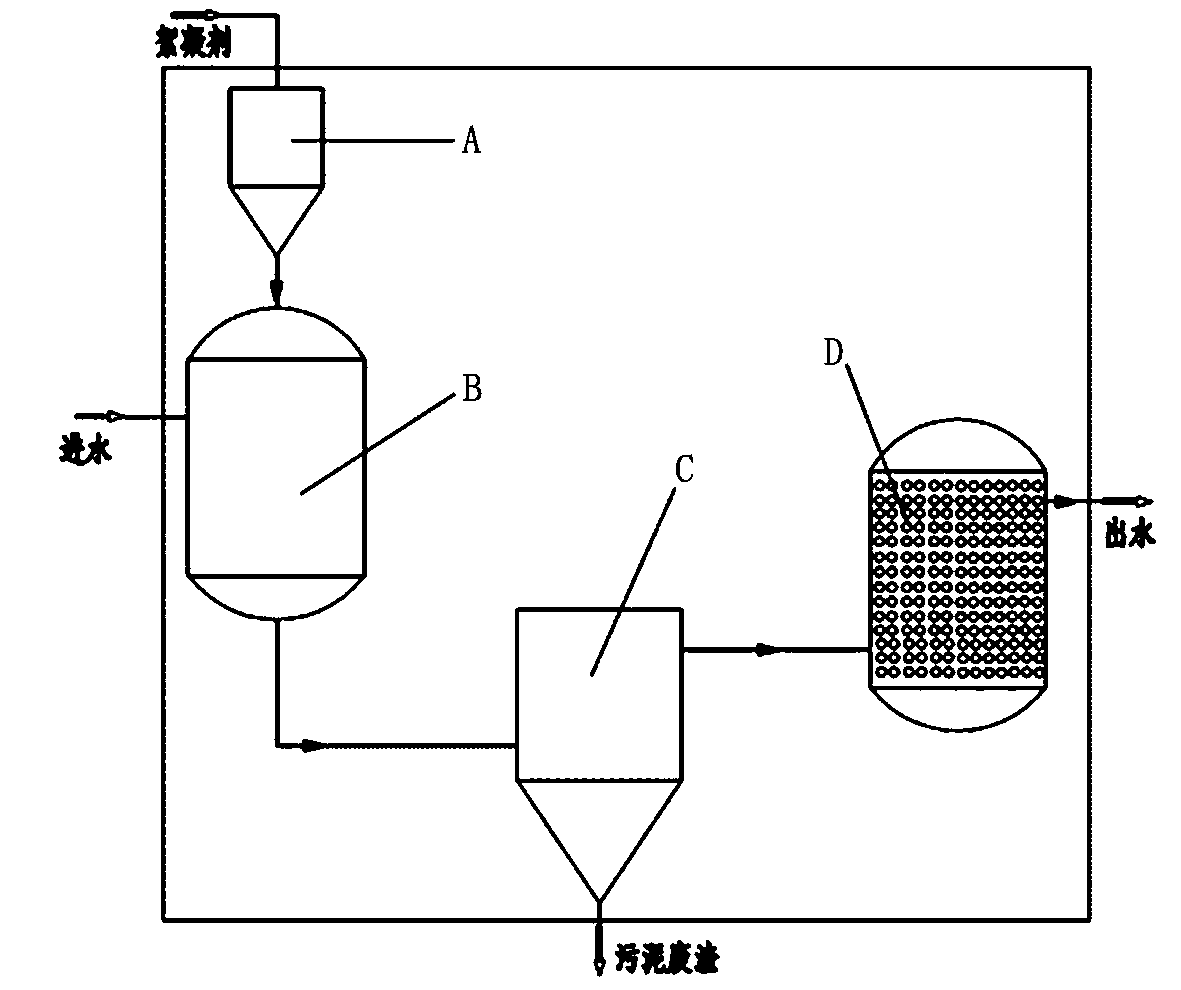

[0048] After the above waste water is adjusted through the mixing pool, it is pumped to the integrated high-efficiency filter to remove turbidity, and then pumped to the first-level photocatalyst reactor by metering, adding H 2 o 2 400kg / h, under the action of TIO2 catalyst (containing Pt1%) and ultraviolet light (wavelength 387.5nm), 84% of carbon-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com