Method for preparing cyanobenzene

A technology of benzonitrile and toluene, which is applied in the field of preparing benzonitrile, can solve the problems of poor selectivity and low catalyst yield, and achieve the effects of reducing unit consumption, increasing reaction yield, and enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

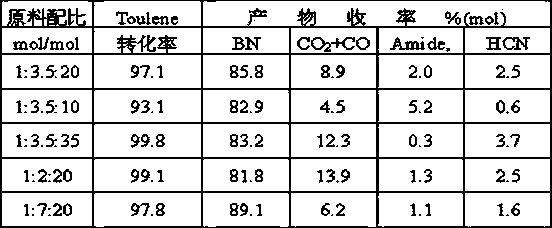

Examples

Embodiment 1

[0052] Catalyst preparation:

[0053] 201 g V 2 o 5 Add it into a solution at a temperature of 80-90° C. consisting of 440 milliliters of water and 420 grams of oxalic acid, stir well, and react to obtain a vanadium oxalate solution.

[0054] 40% (weight) SiO 2 1250 grams of silica sol was slowly added to the above solution under stirring, and then 505 grams of antimony ammonium oxalate [2(NH 4 ) 3 Sb(C 2 o 4 ) 3 2H 2 O] and 300 milliliters of water solution, 68.6 grams of H 3 BO 3 and 560 ml of water and 117.6 g (NH 4 ) 6 Mo 7 o 24 4H 2 A solution consisting of O and 50 ml of water, 0.11 molar phosphoric acid solution, and finally 9.4 g of NaNO 3 And the solution that 20 milliliters of water forms, stirs and mixes, and heating and evaporating to solid content is 42% (weight), obtains viscous slurry.

[0055] The above slurry is sprayed into shape, the gas inlet temperature of the sprayer is 250°C, the outlet temperature is 130°C, the formed catalyst is dried ...

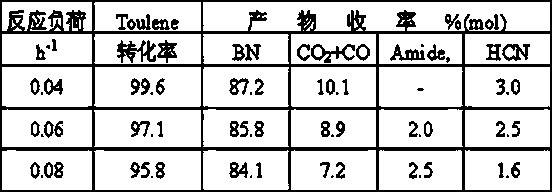

Embodiment 2

[0069] Use the same catalyzer and catalyst amount of embodiment 1, same reaction pressure, reaction load and reaction raw material ratio, change temperature of reaction, evaluate reaction process condition in embodiment 1, its evaluation result is listed in following table 2.

[0070] Table 2 Effect of temperature on reaction

[0071]

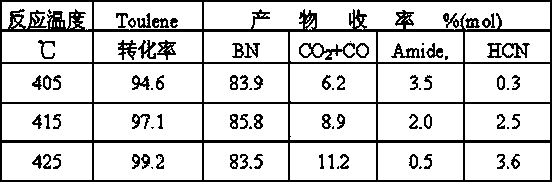

Embodiment 3

[0073] Use the same catalyzer and catalyst amount of embodiment 1, same reaction temperature, reaction load and reaction raw material ratio, change reaction pressure, evaluate reaction process condition in embodiment 1, its evaluation result is listed in following table 3.

[0074] Table 3 Effect of pressure on reaction

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com