Supported composite catalyst for producing high melt strength polypropylene

A high melt strength, composite catalyst technology, applied in the field of polyolefin catalysts, can solve problems such as hindering long-chain branch structures, and achieve the effects of simplifying the preparation process, saving equipment investment and energy investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Prepare a carrier with internal pores of 1.5 nm, particle size of 5.0 μm, external pores of 20 nm and thickness of 20 μm using ZSM-5 molecular sieve material.

[0025] Activated carrier: Take 200 g of the carrier and dry it at 200 ℃ for 2 h under the protection of nitrogen flow, then slowly raise the temperature to 600 ℃ and continue drying for 4 h to obtain the dehydrated carrier. The dehydrated carrier was dispersed in 5 L of hexane solvent, and 0.14 mol of triethylaluminum was added, stirred at 30°C for 2 h, and then dried to obtain a treated carrier.

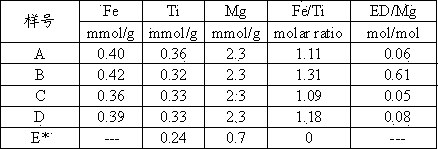

[0026] (2) Take 5 mmol of iron acetylacetonate and 5 mmol of bisiminopyridine ligand and dissolve them in 100 ml of toluene at room temperature. After they are completely dissolved, add 10 g of the treatment carrier, heat up to 50 ℃, and stir. Run for 4 h, wash with toluene 3 times, purge and dry with nitrogen.

[0027] (3) Take 3.0 g of magnesium dichloride, dissolve it in 200 ml of tetrahydrofuran at 60 ℃, add 1 ml of...

Embodiment 2

[0034] (1) Prepare a carrier with an internal pore channel of 1.5 nm, a particle size of 5.0 μm, an external channel of 20 nm, and a thickness of 20 μm using diatomaceous earth materials.

[0035] Activated carrier: Take 200 g of the carrier and dry it at 200 ℃ for 2 h under the protection of nitrogen flow, then slowly raise the temperature to 600 ℃ and continue drying for 4 h to obtain the dehydrated carrier. The dehydrated carrier was dispersed in 5 L of hexane solvent, and 0.1 mol of triethylaluminum (for an alkyl aluminum or alkyl aluminum oxide) was added, stirred at 70°C for 1 h, and then dried to obtain a treated carrier.

[0036] (2) The obtained treatment carrier reduces the load of the late transition metal catalyst to prepare a composite catalyst. Compared with Example 1, the addition amount of iron acetylacetonate and the bisiminopyridine ligand are both 2 mmol, and the internal electron donor is ethyl benzoate. The other catalyst preparation conditions remain unchanged...

Embodiment 3

[0040] (1) Prepare a carrier with internal pores of 1.2 nm, particle size of 4.0 μm, external pores of 30 nm and thickness of 15 μm using montmorillonite material.

[0041] Take 100 g of the carrier and dry it at 200 ℃ for 2 h under the protection of nitrogen flow, then slowly raise the temperature to 600 ℃, and continue to dry for 4 h to obtain the dehydrated carrier. The dehydrated carrier was dispersed in 5 L of hexane solvent, and 0.10 mol of triethylaluminum was added, stirred for 2 h, and then dried to obtain a treated carrier.

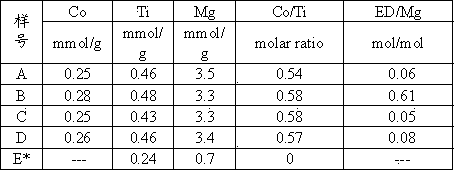

[0042] (2) Take 3 mmol of cobalt chloride and 3 mmol of bisiminopyridine ligand, and dissolve them in 100 ml of toluene at room temperature. After they are completely dissolved, add 10 g of the treatment carrier and raise the temperature to 50 ℃. Stir and run for 4 h, wash with toluene 3 times, and dry with nitrogen.

[0043] (3) Take 5.2 g of magnesium dibromide, dissolve it in 200 ml of ether at 60 ℃, add 1.2 ml of phenyltriethoxysilane and 1 ml of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com