Preparation method of stichopus japonicus microorganism degumming kelp fermented feed

A technology of degumming kelp and fermented feed, applied in animal feed, animal feed, application, etc., to achieve the effects of low cost, reduced damage, and improved digestibility and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Feed raw materials are pretreated, dried until the water content is not higher than 15%, and coarsely crushed to 100-200 mesh; wherein, the feed raw materials are kelp powder, fish meal, sea mud, shell powder, and compound vitamins and minerals.

[0021] Step 2: Weigh 5kg of kelp powder, 1kg of fish meal, 3kg of sea mud, 0.75kg of shell powder, and 0.25kg of multivitamins and minerals;

[0022] Wherein, the multivitamins and minerals are the same as those of the basal feed of the prior art in terms of added ingredients and quantity. Provide a kind of preferred mode here, described multivitamin and mineral composition are (mgg -1 ): thiamin hydrochloride0.5, riboflavin1.0, nicotinic acid0.75, pyridoxine hydrochloride 1.5, vitamin B 12 0.05, calcium pantothenate 10, L-ascorbyl-2-monophosphate-Mg50, choline chloride200, menadione2, retinol acetate 0.6, Vitamin E 10, α-cellulose 723.6; MgSO 4 -7H 2 O 100,ZnSO 4 -7H 2 O 3 , CoCl 2 -6H 2 O 1,MnSO 4 -H 2 O 1,...

Embodiment 2

[0029] Step 1: Pretreatment of feed raw materials, drying until the water content is not higher than 15%, and coarsely crushing to 100-200 mesh;

[0030] Among them, the feed raw materials are kelp powder, fish meal, sea mud, shell powder and complex vitamins and minerals.

[0031] Step 2: Weigh 5.5kg of kelp powder, 1kg of fish meal, 2.5kg of sea mud, 0.8kg of shell powder, and 0.2kg of multivitamins and minerals;

[0032] Step 3: After weighing, the raw materials are placed in a mixer and fully stirred, and mixed to obtain the basic feed;

[0033] Step 4: Weigh 0.01kg of sodium alginate and 0.01kg of urea, dissolve them together with 0.25kg of the above-mentioned mixed bacteria powder in 0.35kg of sterile water with a salt content of 1%, and mix the resulting solution into the basic feed; (it can also be dissolved alginate and urea, added to the basal feed along with probiotics).

[0034] Wherein, the mixed bacteria powder is the mixed bacteria powder of Bacillus flexus, B...

Embodiment 3

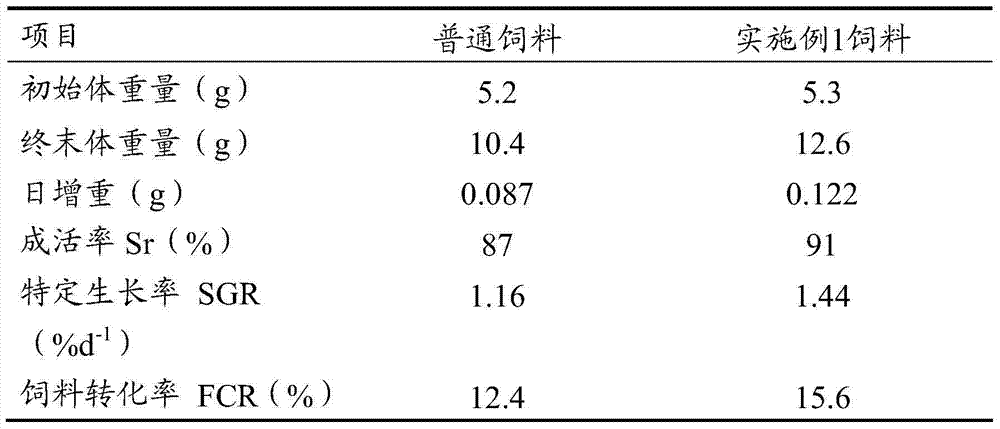

[0038] Healthy sea cucumbers of similar size were selected as experimental subjects, weighing 5±0.3g. Investigate the difference between the above-mentioned invention fermented feed and common sea cucumber feed on the growth performance of sea cucumber. Among them, the common sea cucumber feed is produced by Dalian Sym Bioengineering Co., Ltd., and its components are 45% eel algae powder, 25% sea mud, 5% fish meal, 20% soybean meal powder, 2% vitamins and minerals, and 3 wheat starch. %. Before the start of the experiment, carry out adaptive temporary breeding. All breeding boxes are aerated for 24 hours, using a flowing water system, avoiding light, changing 30% of the breeding water every day, and sucking low sewage once a week. During the whole experiment, dissolved oxygen ≥ 6mg / l, The water temperature is maintained at 16-18°C, the pH is 7.9-8.1, and the salinity is 30-32ppt. The above-mentioned two feeds were fed at fixed times every day, and the feeding amount was 5% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com