Three-dimensional graphene-based nanometer metal composite material, preparation method and application thereof

A graphene-based, composite material technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, other chemical processes, etc., can solve problems such as loss of nano-scale particles, loss of activity, and difficulty in recycling , to achieve the effect of fast adsorption, easy recovery and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

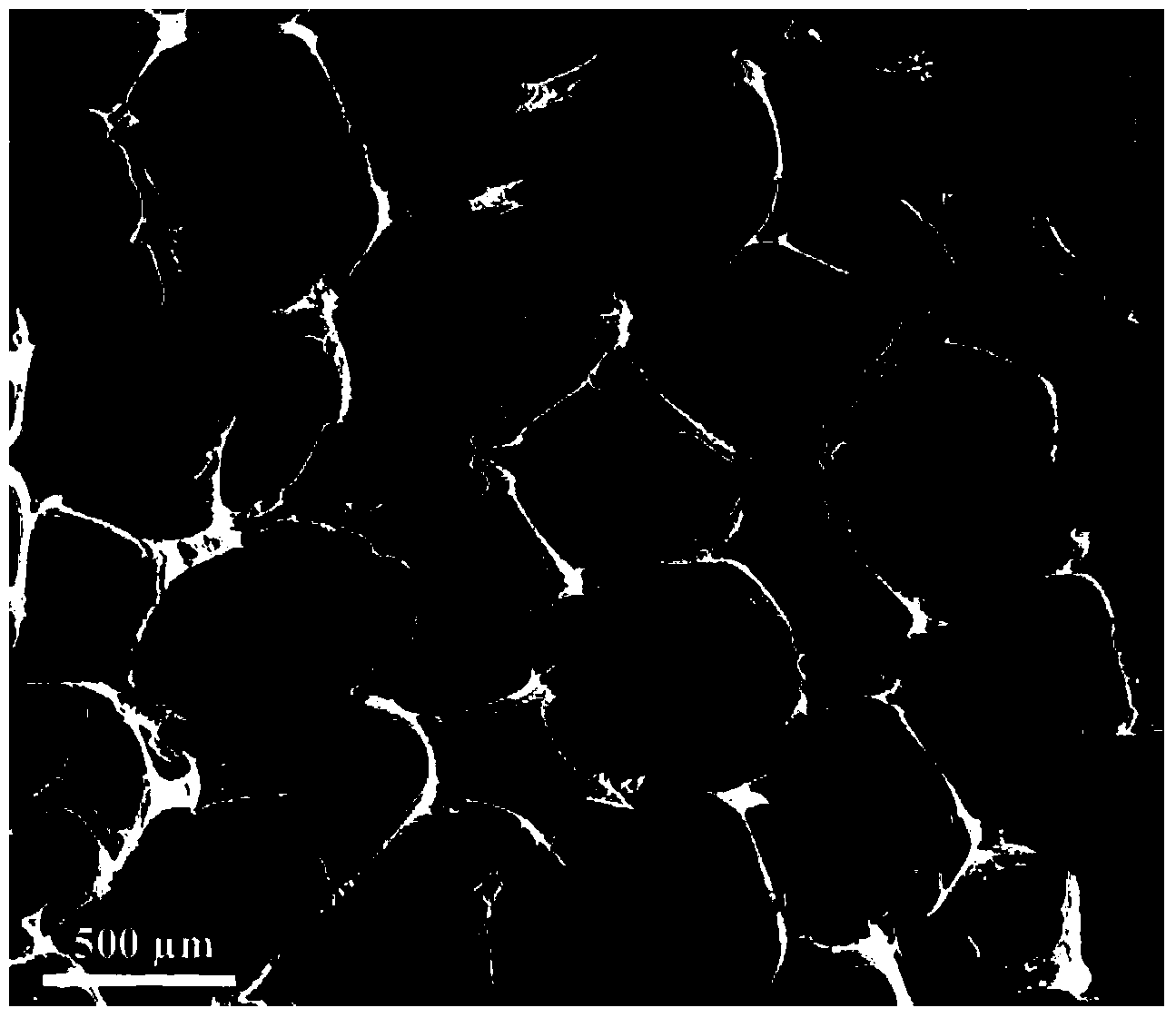

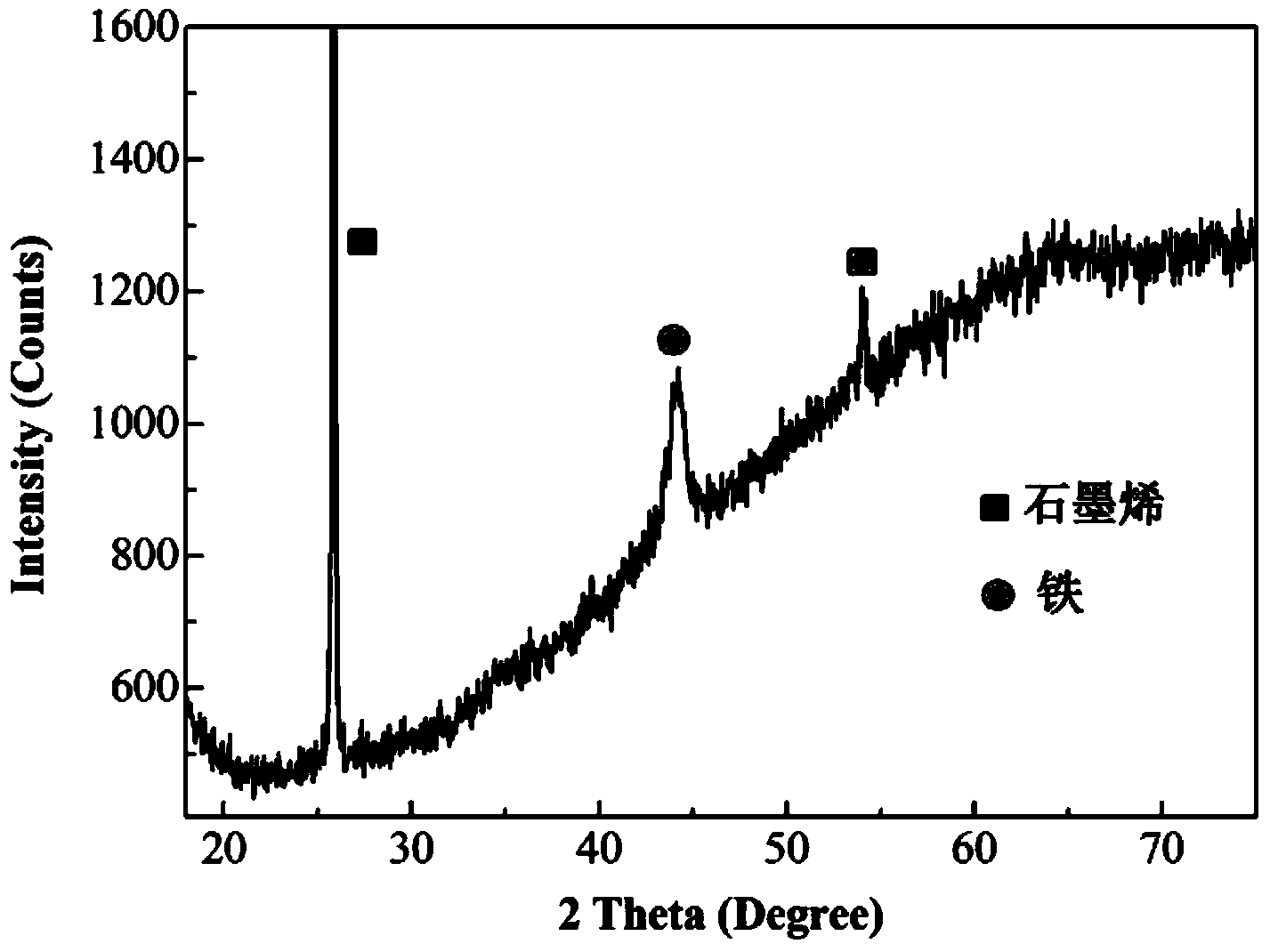

[0037] Put the three-dimensional graphene foam into the plasma processor for pretreatment under air atmosphere for 1 min, then rinse it with absolute ethanol, dry it and seal it for later use; add the pretreated graphene to a container containing 100 ml, In the three-necked flask of 0.05 M ferrous sulfate solution, mechanically stir it for 3 min in advance, and the stirring speed is 250 r / min; then slowly add 50 ml, 0.1 M sodium borohydride solution into the three-necked flask, and at the same time, pass in nitrogen for protection , mechanically stirred at 20 oC, the stirring speed was 150 r / min, and the reaction time was 30 min; after that, the solution was filtered out, and the sample was washed repeatedly with deionized water and absolute ethanol, and then put into a vacuum drying oven After drying at 80 oC for 5 h, the obtained sample is a graphene-based nano-iron composite material, and the mass ratio of the nano-metal to graphene is 0.5-5:1.

[0038] Add 200 mg of the ab...

Embodiment 2

[0043] Put the three-dimensional graphene foam into the plasma processor for pretreatment in the air atmosphere for 3 min, then rinse with absolute ethanol, dry it and seal it for future use; add the pretreated graphene to a container containing 100 ml, In the three-necked flask of 0.1 M ferrous sulfate solution, mechanically stir it for 3 minutes in advance, and the stirring speed is 250 r / min; then slowly add 50 ml, 0.2 M sodium borohydride solution into the three-necked flask, and at the same time, pass in nitrogen for protection , mechanically stirred at 20 oC, the stirring speed was 250 r / min, and the reaction time was 15 min; after that, the solution was filtered out, and the sample was washed repeatedly with deionized water and absolute ethanol, and then put into a vacuum drying oven After drying at 80 oC for 5 h, the obtained sample is the graphene-based nano-iron composite.

[0044] Add 200 mg of the above-mentioned graphene-based nano-iron to 50 ml of a solution cont...

Embodiment 3

[0048]Put the three-dimensional graphene foam into the plasma processor for pretreatment in the air atmosphere for 3 min, then rinse with absolute ethanol, dry it and seal it for future use; add the pretreated graphene to a container containing 100 ml, In the three-necked flask with 0.2 M ferrous sulfate solution, mechanically stir it for 3 min in advance, and the stirring speed is 250 r / min; then slowly add 50 ml, 0.4 M sodium borohydride solution into the three-necked flask, and at the same time, pass in nitrogen for protection , mechanically stirred at 20 oC, the stirring speed was 250 r / min, and the reaction time was 15 min; after that, the solution was filtered out, and the sample was washed repeatedly with deionized water and absolute ethanol, and then put into a vacuum drying oven After drying at 80 oC for 5 h, the obtained sample is the graphene-based nano-iron composite. Add nickel chloride to 50 ml aqueous solution containing graphene-based nano-iron, the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com