Preparation method of copper nano material taking amino acid and analogs of amino acid as modifier

A technology of copper nano and modifiers, which is applied in the field of preparation of copper nanomaterials to control the morphology and size, and can solve problems such as easy aggregation, chemical stability, and poor dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] Preparation of Copper Nanomaterials

[0082] The present invention also provides a method for preparing the material as described above, characterized in that it comprises the steps of:

[0083] (1) In an inert medium, add alkali, copper salt and modifier, and mix thoroughly to form a reaction system with pH ≥ 11; preferably, the pH of the system ≥ 12, more preferably ≥ 13.

[0084] (2) Under an inert atmosphere, a reducing agent is added to the reaction system for reaction to obtain copper nanomaterials.

[0085] Wherein, the reaction medium may be a medium selected from (but not limited to) the following group: water, alcohol solvent, amide solvent, sulfoxide solvent, or a combination thereof;

[0086] The base is not particularly limited, and may be (but not limited to) a base selected from the group consisting of sodium hydroxide, potassium hydroxide, ammonia, or a combination thereof; preferably, the base is a strong base, with Keep the system pH in the desired r...

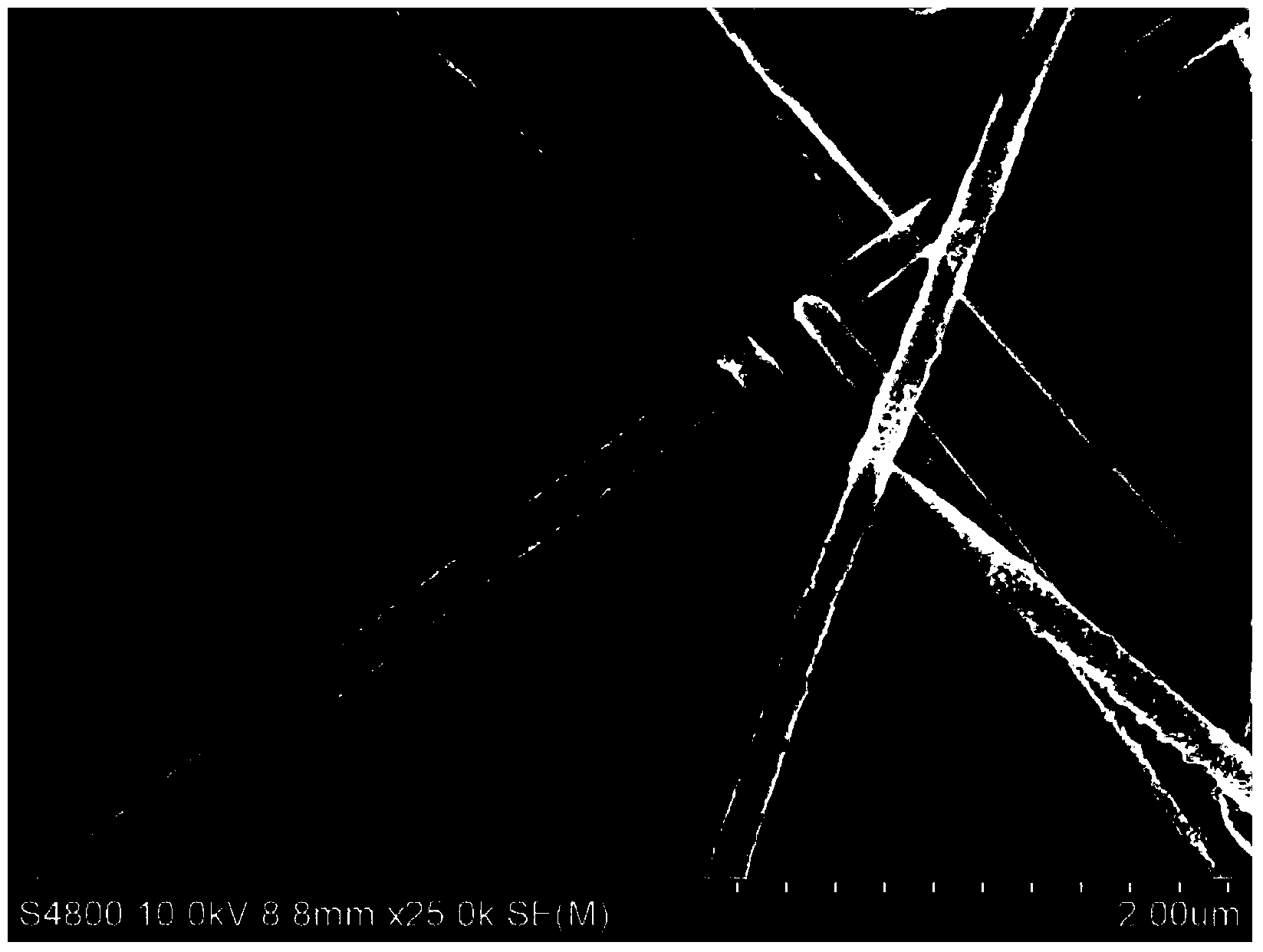

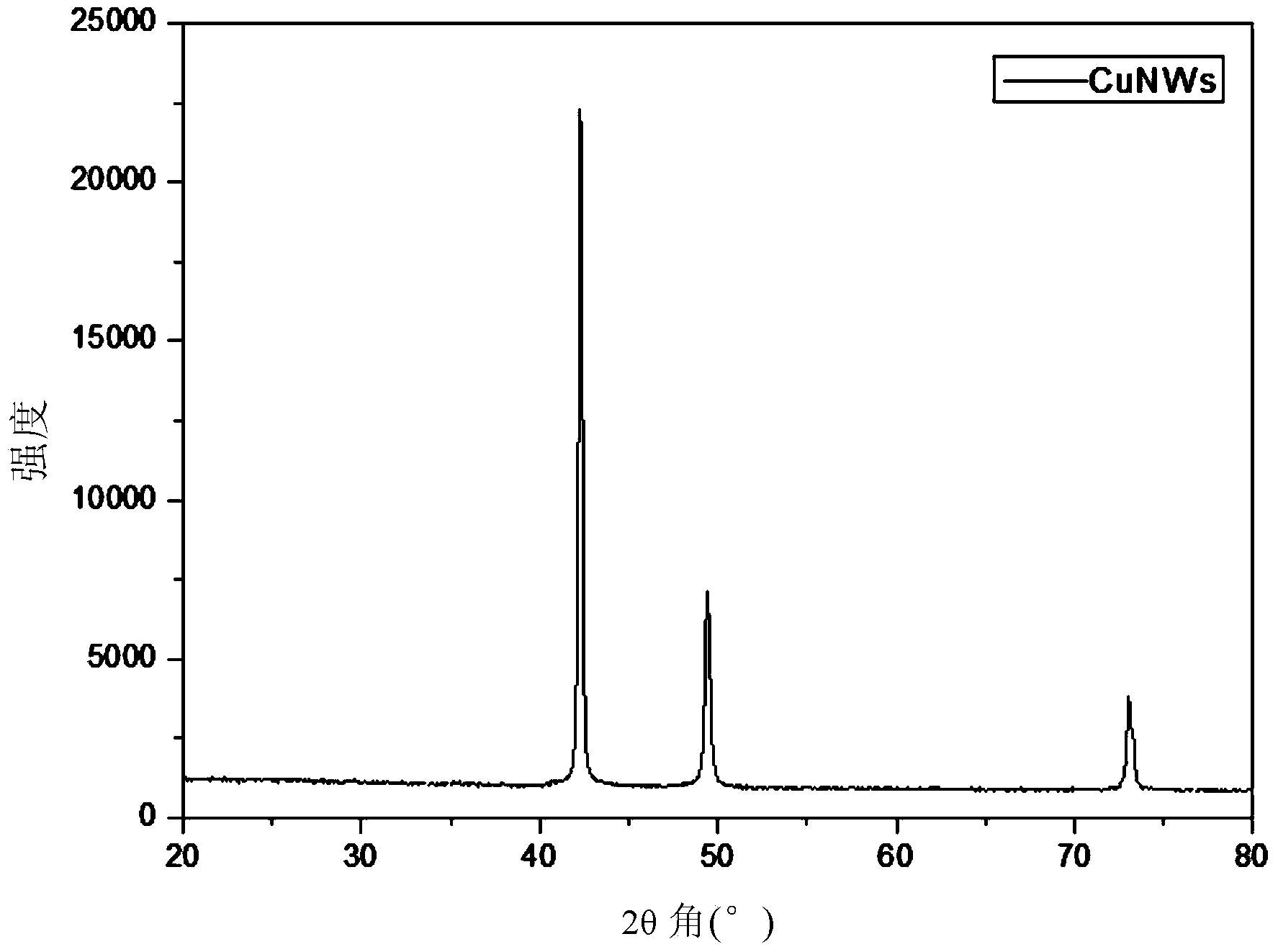

Embodiment 1

[0109] Add 2.42g of sodium hydroxide and 80mL of deionized water into the two-necked flask in sequence, and stir to dissolve all the sodium hydroxide; when the system is cooled to room temperature, add 20mL of copper nitrate solution with a concentration of 0.1M and 2.80g of glycine in sequence, and continue stirring; Then drop 50 μL of hydrazine hydrate solution with a concentration of 35%. When the system starts to change color, heat the system to 60-90°C and continue stirring for 30-60 minutes, and a red solid is formed. Then filter with a water-based microporous filter membrane with a diameter of 50 mm and a pore size of 0.45 μm, and wash with a large amount of deionized water to obtain copper nanowires.

Embodiment 2

[0111] The preparation method is basically the same as in Example 1, except that the added surface modifier is glycine with a mass of 6.28 g, and the obtained product is copper nanowires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com