Method for preparing graphene powder material and graphene powder material

A graphene powder and bulk material technology, applied in the method and graphene powder material, the field of preparing graphene powder material, can solve the problems of complex process, high cost, graphene defects, etc., and achieves simple process, raw materials and The effect of low requirements on equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

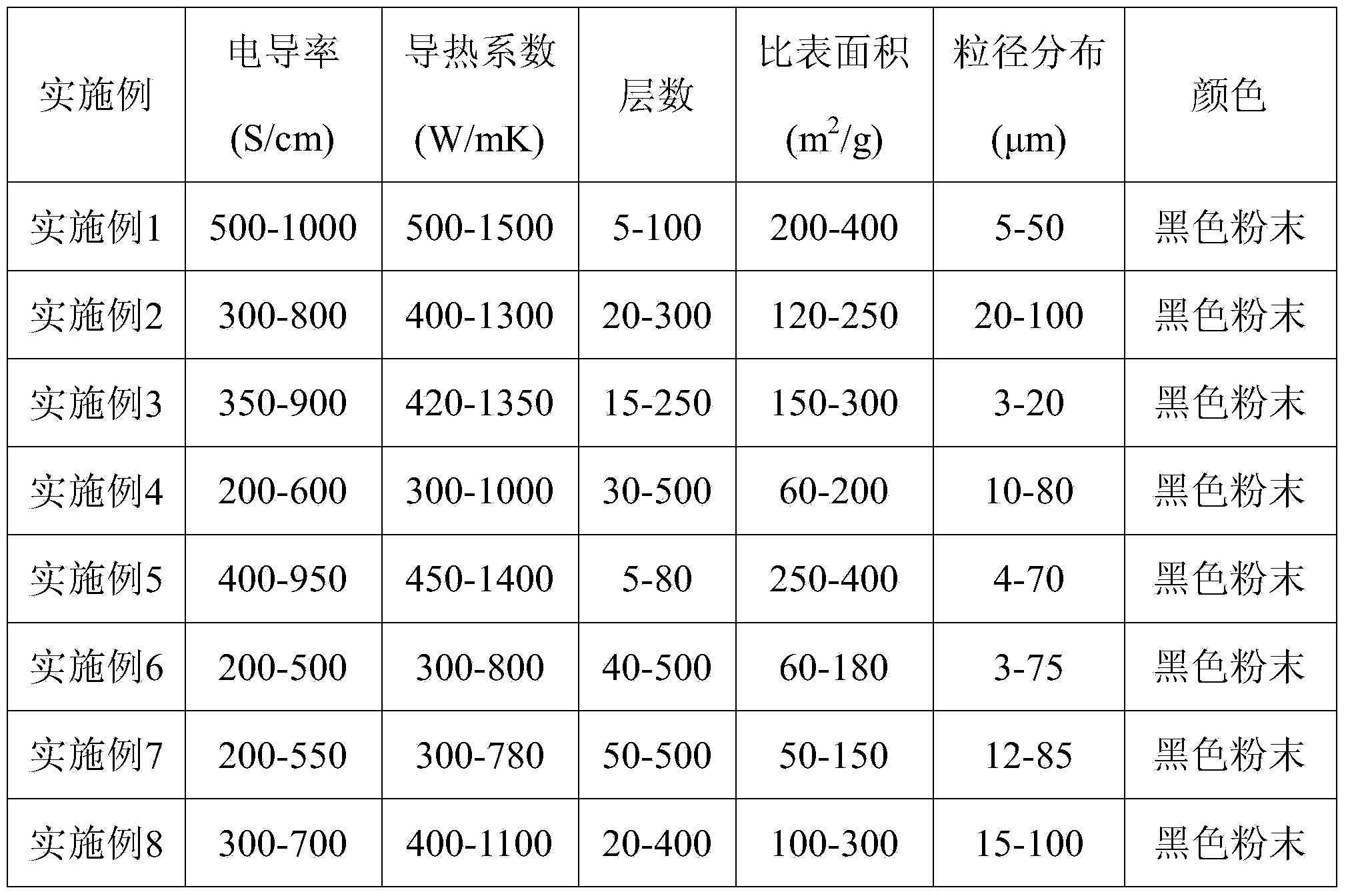

Embodiment 1

[0039] Put 1g of 1000-mesh natural flake graphite with a carbon content of 99% into the reaction kettle, add 10mL of 80% sulfuric acid solution and mix well, then add 1.2g of KMnO 4 And control the temperature at 30°C, stir and react for 60min, slowly add deionized water to the reaction system, and control the reaction temperature not to exceed 95°C, after the temperature of the reaction mixture drops to room temperature, centrifuge and wash with water for more than 4 times, and then in 75 ℃ drying; under the condition of microwave expansion power of 420W, expand for 50s; according to the mass ratio of graphite expansion intermediate and N-methylpyrrolidone 2%, put it into the ball mill, grind for 5h to obtain graphene slurry, and then Spray drying to obtain graphene powder material.

Embodiment 2

[0041] Put 1g of 30-mesh natural flake graphite with a carbon content of 94% into the reactor, add 5mL of 98% sulfuric acid solution and mix well, then add 3.0g (NH 4 ) 2 S 2 o 8 And control the temperature at 60°C, stir and react for 120min, slowly add deionized water to the reaction system, and control the reaction temperature not to exceed 95°C, after the temperature of the reaction mixture drops to room temperature, centrifuge and wash with water for more than 4 times, and then freeze Drying; under the condition of microwave expansion power of 700W, expand for 30s; according to the mass ratio of graphite expanded intermediate and N,N-dimethylformamide, put it into a sand mill, grind for 12h to obtain graphene slurry, Then spray drying to obtain graphene powder material.

Embodiment 3

[0043] Put 1g of 2500-mesh natural flake graphite with a carbon content of 98% into the reactor, add 20mL of 50% sulfuric acid solution and mix well, then add 2.5g of K 2 Cr 2 o 7 And control the temperature at 40°C, stir and react for 40min, slowly add deionized water to the reaction system, and control the reaction temperature not to exceed 95°C, after the temperature of the reaction mixture drops to room temperature, centrifuge and wash with water for more than 4 times, and then in 60 Dry at ℃; under the condition of microwave expansion power of 140W, puff for 20s; according to the mass ratio of graphite puffed intermediate to N,N-dimethylacetamide 1.5%, put it into a sand mill, and sand mill for 10h to obtain graphene Slurry is then spray-dried to obtain graphene powder material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com