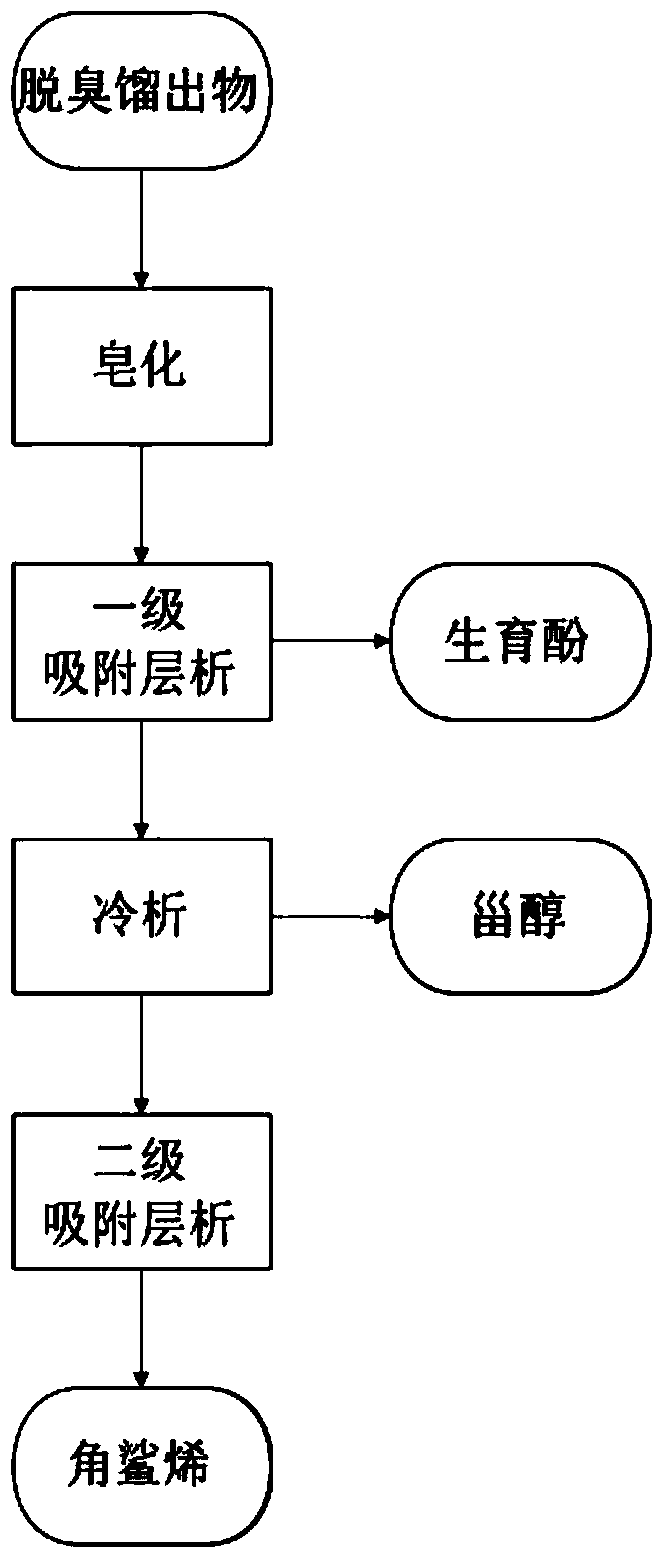

Method for extracting squalene in vegetable oil deodorizer distillate through two-stage column chromatography

A technology for deodorizing distillate and column chromatography, which is applied in the directions of steroids, adsorption purification/separation, chemical change purification/separation, etc. Extraction rate, short-term return, high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This example will adopt the method that saponification pretreatment and secondary column chromatography combine to extract the squalene in soybean oil deodorization distillate, concrete implementation steps are:

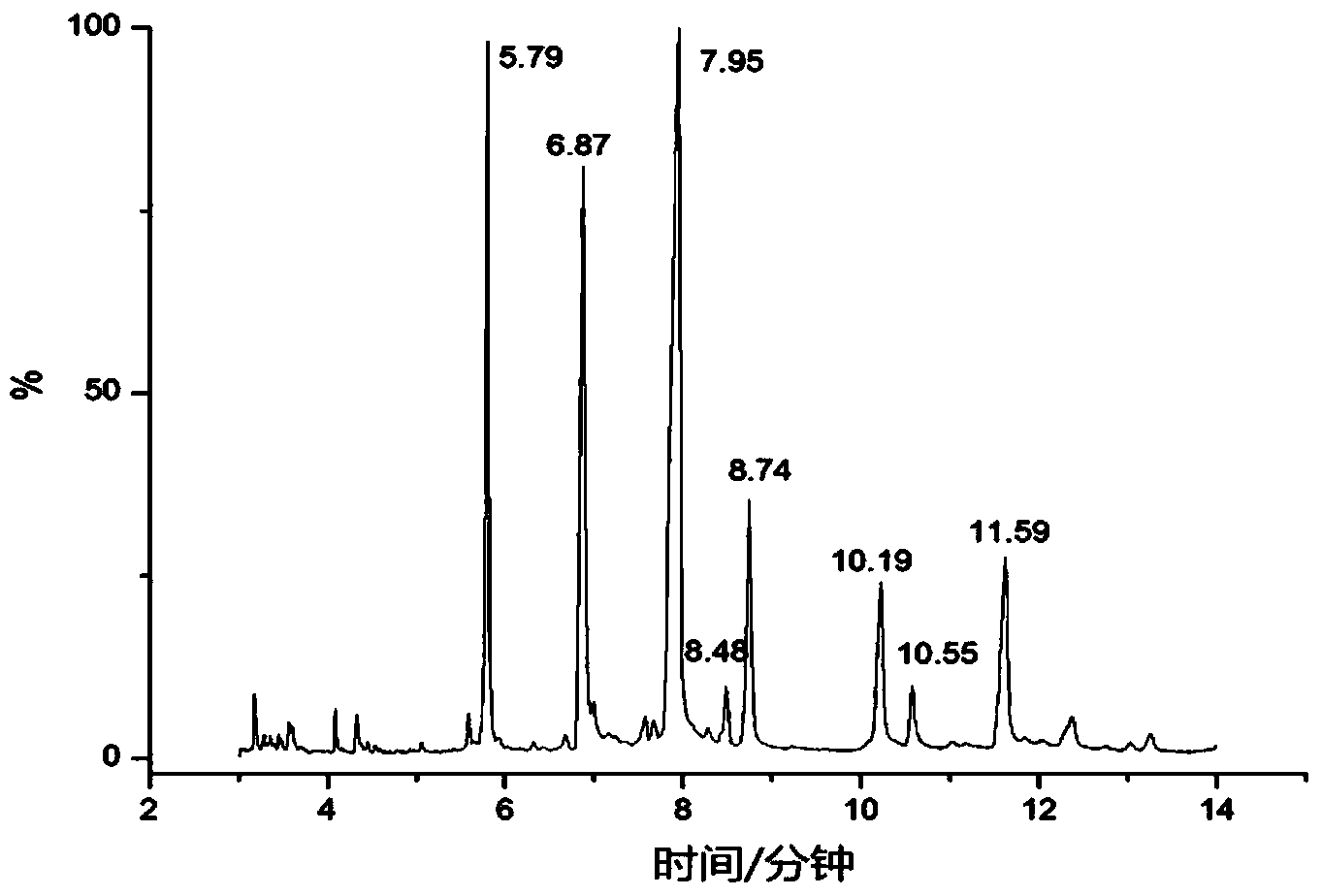

[0043] 1. Separation of unsaponifiable matter: Take 108g of soybean oil deodorization distillate (squalene content 1.96%), add a small amount of TBHQ as a protective agent, add 1.5mol / L NaOH-methanol solution 320ml under stirring, 80℃ Saponify under reflux for 1 hour. After the reaction, add 300ml of distilled water, stir for 2 minutes, take it out and cool to room temperature. Petroleum ether was extracted three times, 500 mL each time, the petroleum ether layer was combined, and the petroleum ether layer was washed with 5% brine until neutral. After the petroleum ether layer was dehydrated, the solvent was removed by rotary evaporation at 60°C to obtain unsaponifiable matter, which was detected by GC-MS (attached figure 2 ), the content of squalene in unsa...

Embodiment 2

[0049] In this example, a combination of saponification pretreatment and secondary column chromatography will be used to extract squalene from rice bran oil deodorization distillate. The specific implementation steps are:

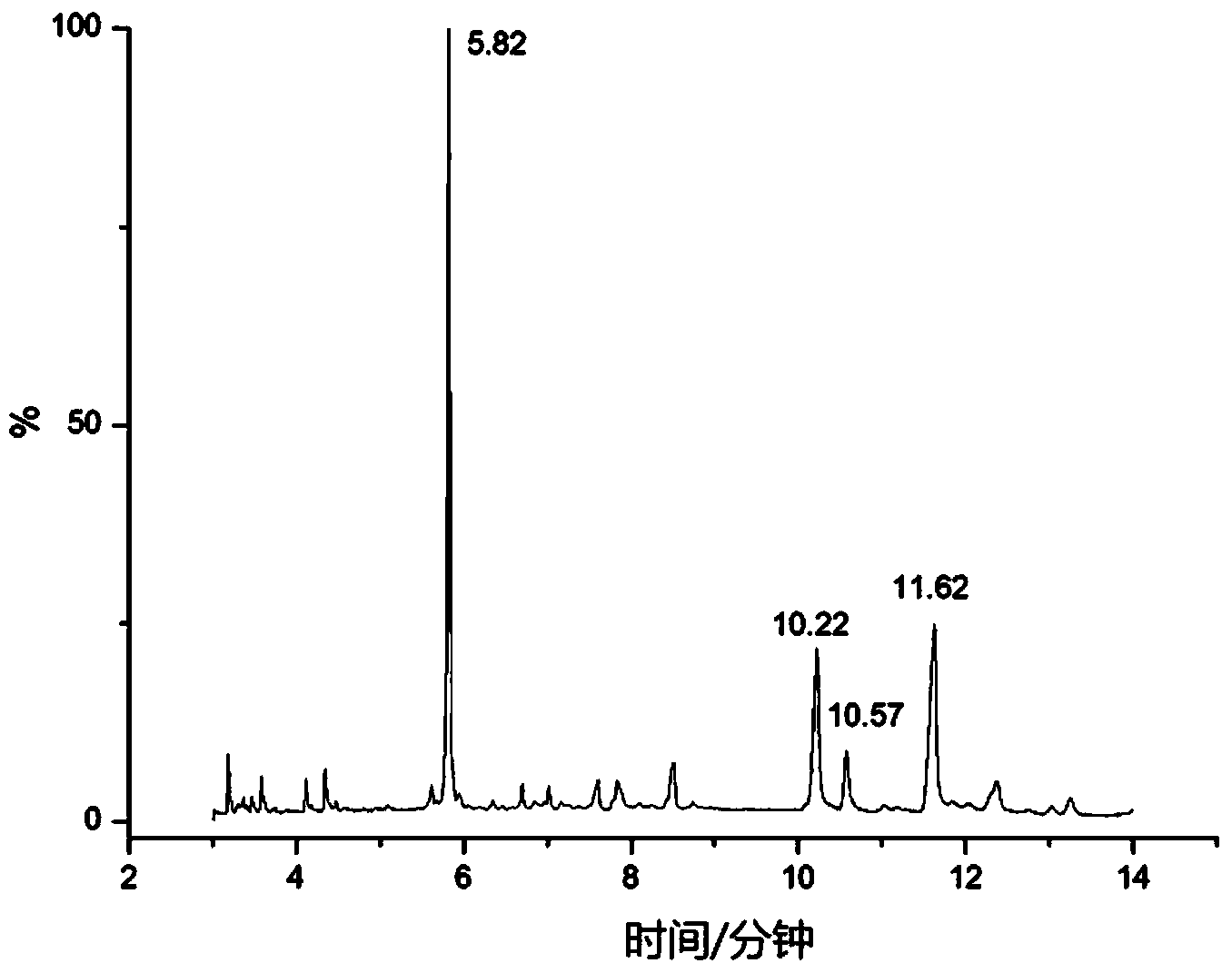

[0050] 1. Separation of unsaponifiable matter: Take 100g of rice bran oil deodorization distillate (0.86% squalene content), put the distillate into a three-neck round bottom flask, add a small amount of BHA as a protective agent while stirring, and then add 1.5mol / L KOH-ethanol solution (the amount added is 1.5 times the theoretical amount), reflux saponification at 80°C for 1.5h, after the reaction, add 300ml of distilled water, stir for 2 minutes, take it out and cool to room temperature. Extract with n-hexane three times, 500 mL each time, combine the n-hexane layers, and wash the n-hexane layers with 5% brine until neutral. After the n-hexane layer was dehydrated, the solvent was removed by rotary evaporation at 60°C, and the unsaponifiable matter wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com