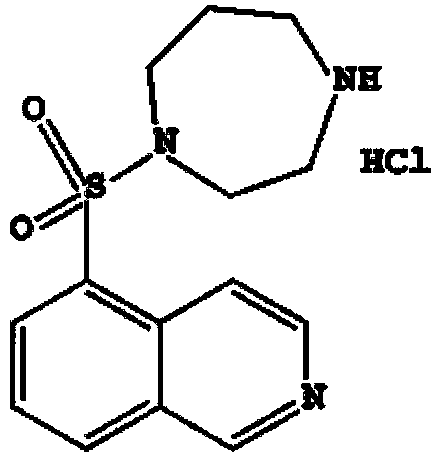

High-purity fasudil hydrochloride preparation method

A high-purity technology of fasudil hydrochloride, which is applied in the field of preparation of high-purity fasudil hydrochloride, can solve the problems of affecting the yield of finished products, safety accidents, and difficult removal of impurities, so as to improve product purity and avoid excessive Acidification, beneficial to the effect of direct removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

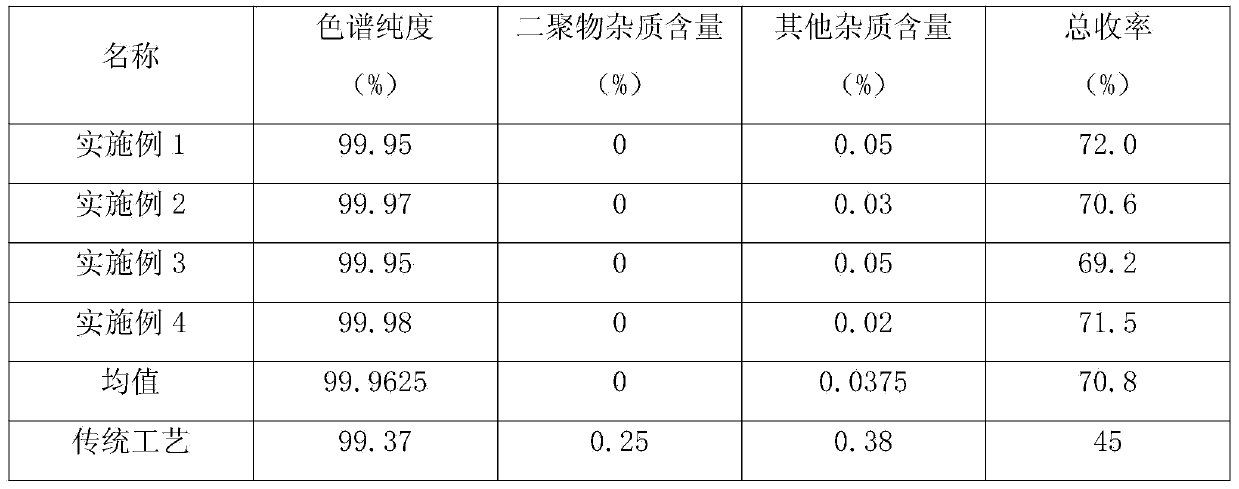

Examples

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of high-purity fasudil hydrochloride, it comprises the following steps:

[0027] S1. Weighing: Weigh isoquinoline-5-sulfonyl chloride hydrochloride and homopiperazine in a molar weight ratio of 1:1.5;

[0028] S2. Preparation of isoquinoline-5-sulfonyl chloride solution: add 10 mg / ml of anhydrous sodium sulfate with a total solution volume of 10 mg / ml to the dichloromethane solution, add isoquinoline-5-sulfonyl chloride hydrochloride after stirring for 25 min, and then add solid Sodium bicarbonate is alkalized, filtered until no bubbles are generated, and the obtained liquid is cooled to a temperature of 10 ° C for subsequent use; wherein, the weight ratio of the dichloromethane to isoquinoline-5-sulfonyl chloride hydrochloride is 5:1 ;

[0029] S3. the preparation of homopiperazine solution: dissolving homopiperazine with absolute ethanol, and cooling to 10°C of solution temperature; the weight ratio of the absolute ethanol a...

Embodiment 2

[0034] Embodiment 2: a kind of preparation method of high-purity fasudil hydrochloride, it comprises the following steps:

[0035] S1. Weighing: weigh isoquinoline-5-sulfonyl chloride hydrochloride and homopiperazine in a molar weight ratio of 1:2;

[0036] S2. Preparation of isoquinoline-5-sulfonyl chloride solution: add total solution volume 50mg / ml anhydrous sodium sulfate to dichloromethane solution, add isoquinoline-5-sulfonyl chloride hydrochloride after stirring for 35min, and then add solid Sodium bicarbonate is alkalized, filtered until no bubbles are generated, and the obtained liquid is cooled to a temperature of 8 ° C for subsequent use; wherein, the weight ratio of the dichloromethane to isoquinoline-5-sulfonyl chloride hydrochloride is 20:1 ;

[0037] S3. the preparation of homopiperazine solution: dissolving homopiperazine with absolute ethanol, cooling to solution temperature 7 ℃; The weight ratio of described absolute ethanol and homopiperazine is 20:1;

[0...

Embodiment 3

[0042] Embodiment 3: a kind of preparation method of high-purity fasudil hydrochloride, it comprises the following steps:

[0043] S1. Weighing: weigh isoquinoline-5-sulfonyl chloride hydrochloride and homopiperazine in a molar weight ratio of 1:1.6;

[0044] S2. Preparation of isoquinoline-5-sulfonyl chloride solution: add the total solution volume of 25mg / ml anhydrous sodium sulfate to the dichloromethane solution, add isoquinoline-5-sulfonyl chloride hydrochloride after stirring for 28min, and then add solid Sodium bicarbonate is alkalized, filtered until no bubbles are generated, and the obtained liquid is cooled to a temperature of 5 ° C for subsequent use; wherein, the weight ratio of the dichloromethane to isoquinoline-5-sulfonyl chloride hydrochloride is 10:1 ;

[0045] S3. the preparation of homopiperazine solution: dissolving homopiperazine with absolute ethanol, cooling to solution temperature 7 ℃; The weight ratio of described absolute ethanol and homopiperazine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com