Method for preparation of graphene water dispersion by reduction of graphene oxide with gellan gum polysaccharide

A technology of graphene and dispersion liquid, which is applied in the field of graphene aqueous dispersion prepared by using gellan gum polysaccharide to reduce graphene oxide, which can solve the problems of poor dispersion of graphene, complicated process, high toxicity, etc., and achieve good dispersion stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

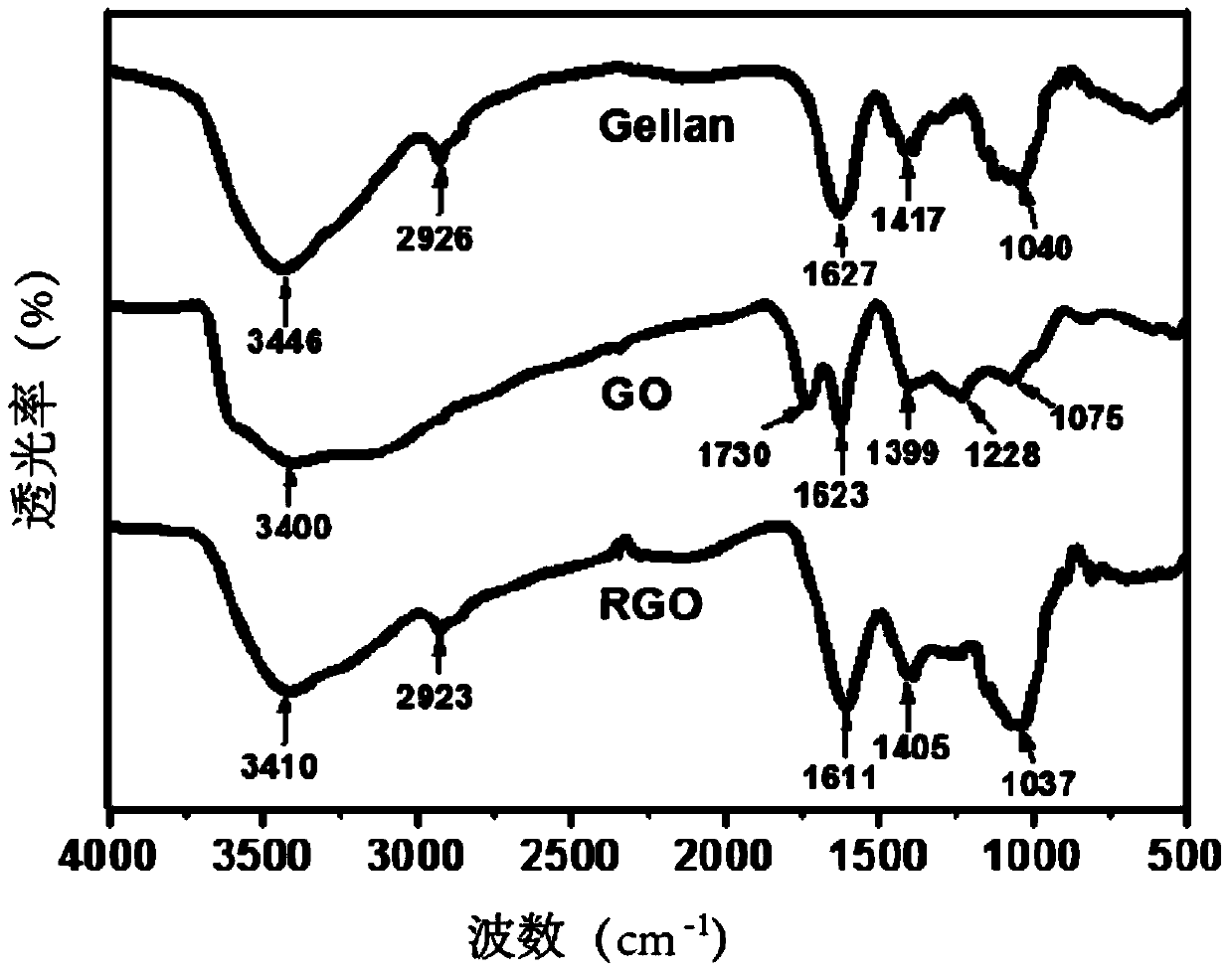

[0033] Preparation of Graphene Oxide

[0034] The preparation of graphene oxide adopts the classic Hummers method: in ice water, 69ml of 98% concentrated sulfuric acid is added to 3g of natural flake graphite and 1.5g of NaNO 3 In the mixture, stirring is maintained for 10-20min to mix the reactants evenly; then, weigh 9gKMnO 4 Slowly add to the above reaction solution, keep the system temperature at 20°C throughout the process, and react for 2 hours; then raise the temperature of the reaction solution to 35°C, and continue the reaction for 30 minutes; then slowly add 138ml of deionized water to the entire reaction system, the system A large amount of heat is released, causing the temperature of the whole system to rise to 98°C, and maintain at this temperature for 15 minutes; after the reaction is completed, add 420ml of deionized water and 3ml of H to the solution 2 o 2 Reduction of excess KMnO4, it can be observed that the mixed solution continuously has bubbles, and the ...

Embodiment 1

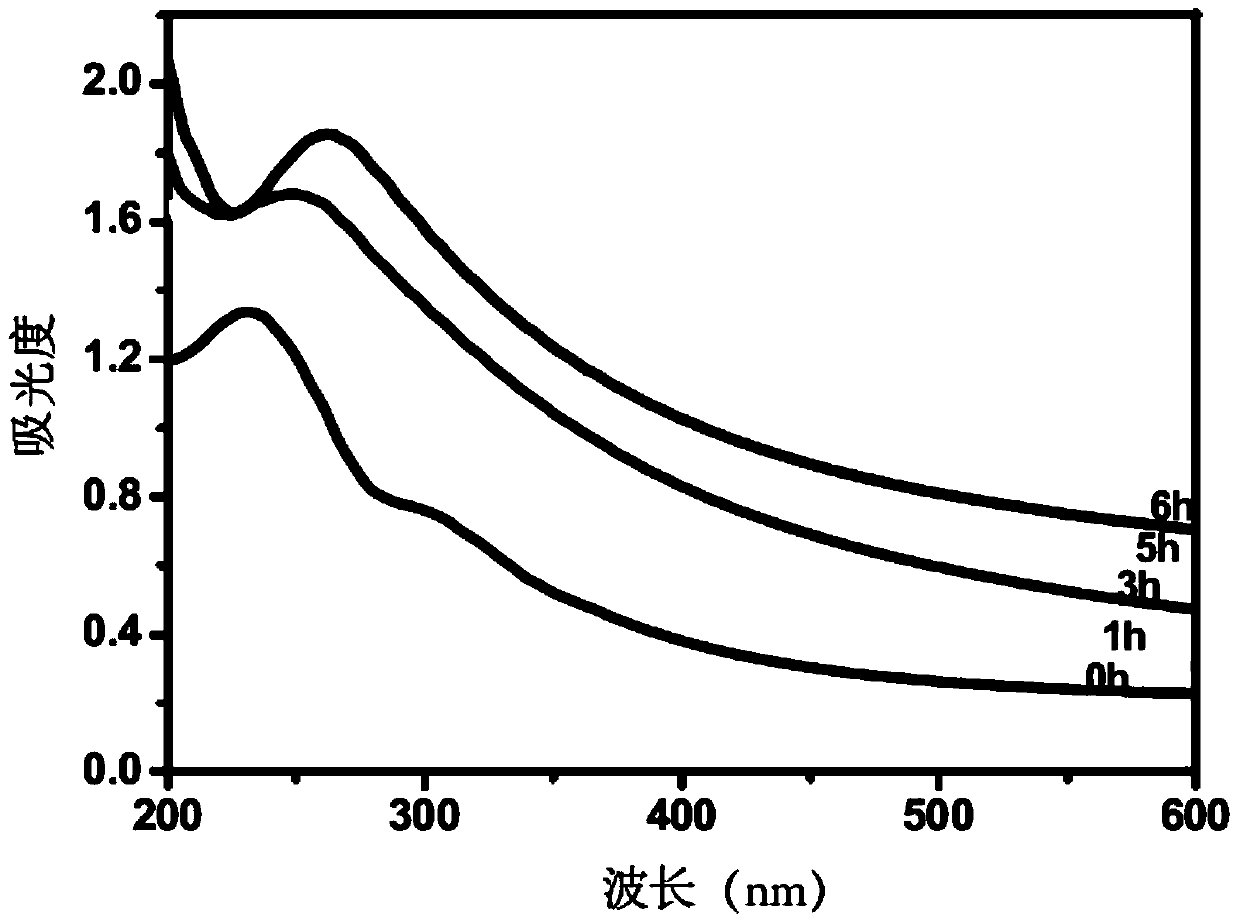

[0037] In a 250ml round bottom flask, stir and disperse 1g of gellan gum with a molecular weight of 100WDa in 100ml of deionized water, heat the dispersion at 85°C for 13min, and cool to room temperature to obtain a 10mg / ml gellan gum solution. Add 50 mg of graphene oxide to the above gellan gum solution, and ultrasonicate at a frequency of 40 KHz for 10 min to obtain a mixture of gellan gum and graphene oxide. Then, the pH of the mixed solution was adjusted to 10 with ammonia water with a mass concentration of 20%, and finally the temperature of the reaction mixed system was raised to 85° C. for 6 h. After the reaction, the liquid was repeatedly centrifuged and washed three times with 200 ml of deionized water, and the obtained precipitate was dried in a vacuum oven at 40° C. to obtain graphene.

[0038] Take 0.3g graphene and add to 10ml deionized water, ultrasonic 5min under 40KHz frequency condition, obtain 30mg / ml graphene aqueous dispersion liquid, this graphene aqueous ...

Embodiment 2

[0040]In a 250ml round bottom flask, stir and disperse 0.75g of gellan gum with a molecular weight of 60WDa in 100ml of deionized water, heat the dispersion at 80°C for 15min, and cool to room temperature to obtain 7.5mg / ml of gellan gum solution. Add 50 mg of graphene oxide to the above gellan gum solution, and ultrasonicate at a frequency of 35 KHz for 8 minutes to obtain a mixture of gellan gum and graphene oxide. Then, the pH of the mixed solution was adjusted to 10 with ammonia water with a mass concentration of 20%, and then the temperature of the reaction mixed system was raised to 90° C. for 7 hours. After the reaction, the liquid was repeatedly centrifuged and washed three times with 200 ml of deionized water, and the obtained precipitate was dried in a vacuum oven at 40° C. to obtain graphene.

[0041] Take 0.25g of graphene and add it into 10ml of deionized water, and ultrasonicate for 5min under the frequency of 40KHz to obtain a 25mg / ml graphene water dispersion....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

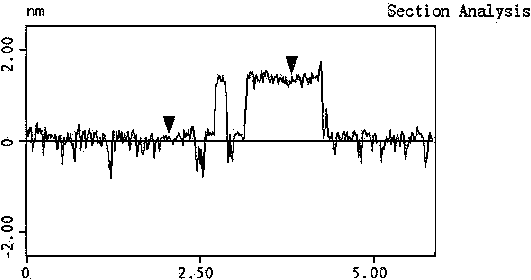

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com