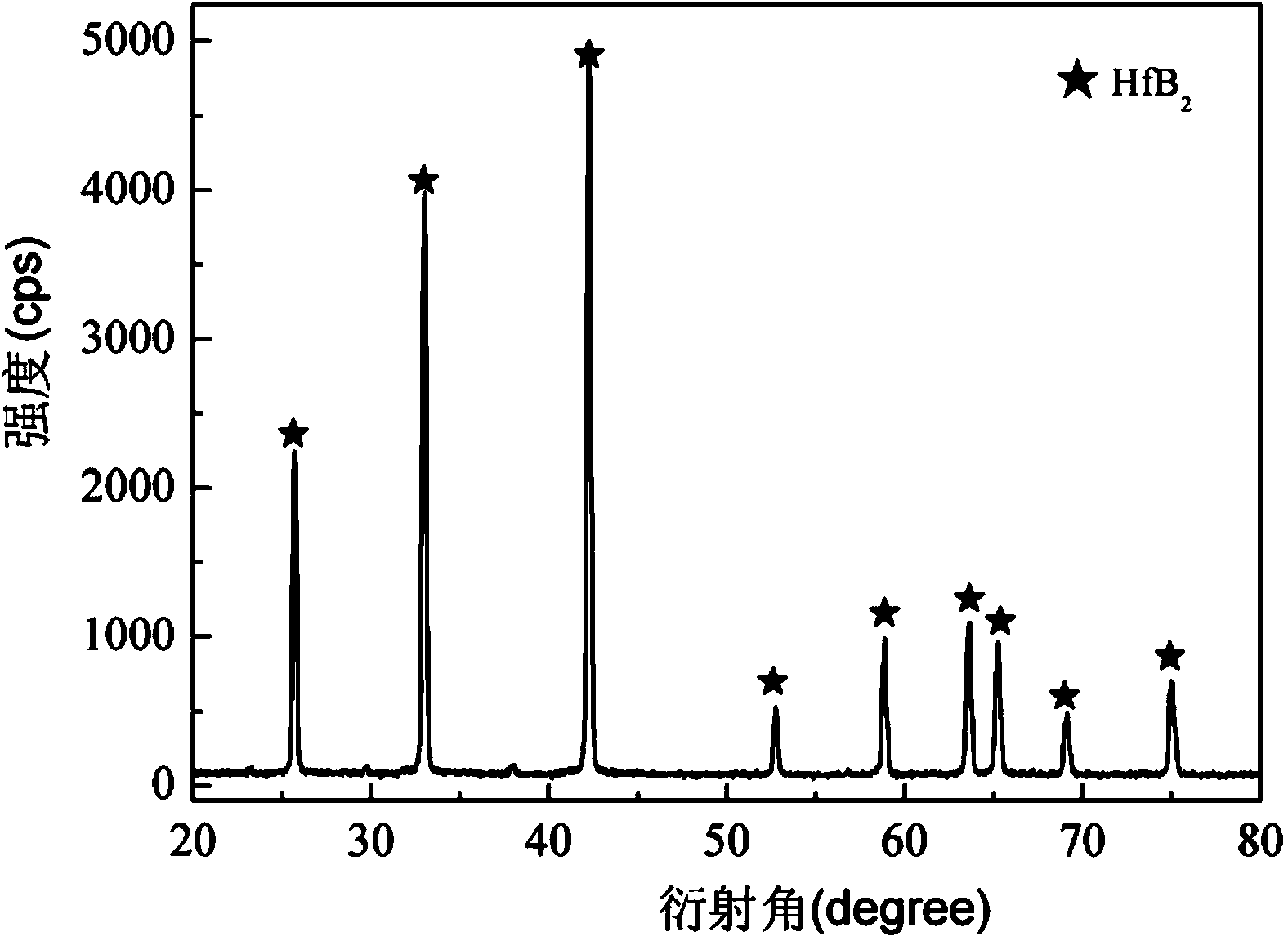

Method for preparing hafnium boride powder by using boron/carbothermic method

A reduction method, hafnium boride technology, applied in the direction of boron/boride, metal boride, etc., can solve the problems of low purity and poor uniformity of powder, and achieve the effect of simple process, short time consumption and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Hafnium oxide (HfO 2 ) as hafnium source, with boron carbide (B 4 C) as a boron source, with sucrose as a carbon source;

[0032] (1) Weigh 100g HfO 2 Powder, its purity is 99.9wt%, and average particle size is 50nm, weighs 16.4g boron carbide (B 4 C) powder, the purity is 96wt%, and the average particle size is 0.8μm. Put the two powders together into a ball mill tank, add absolute ethanol, add zirconia ball mill media, and ball mill for 24 hours. Move the mixed mixture to In a vessel containing 250ml of absolute ethanol, disperse by ultrasonic oscillation for 0.5h;

[0033] (2) Weigh 13.5g of sucrose and add it to 200ml of water, stir to make it evenly mixed, then add it to the solution obtained in step (1), and stir magnetically while heating. The heating temperature is 100°C and the heating time is 8h, and the mixture uniform reactants;

[0034] (3) Put the reactant obtained in step (2) into a graphite crucible, and then put the graphite crucible into a high-puri...

Embodiment 2

[0036] Hafnium oxide (HfO 2 ) as hafnium source, with boron carbide (B 4 C) as a boron source, with sucrose as a carbon source;

[0037] (1) Weigh 100g HfO 2 Powder, its purity is 99.9wt%, and average particle diameter is 100nm, weighs 15.7g boron carbide (B 4 C) powder, the purity is 96.0wt%, and the average particle size is 1 μm. Put the two powders together into a ball mill jar, add absolute ethanol, add zirconia ball mill media, and ball mill for 12 hours. Move the mixed mixture to In a vessel containing 300ml of absolute ethanol, disperse by ultrasonic oscillation for 1h;

[0038] (2) Weigh 27.0g of sucrose and add it to 200ml of water, stir to make it evenly mixed, then add it to the solution obtained in step 1), and stir magnetically while heating. reactant;

[0039] (3) Put the reactant obtained in step (2) into a graphite crucible, and then put the graphite crucible into a high-purity argon-protected heat treatment furnace for heating. The heating program is to h...

Embodiment 3

[0041] Hafnium oxide (HfO 2 ) as hafnium source, with boron carbide (B 4 C) as a boron source, with sucrose as a carbon source;

[0042] (1) Weigh 100g HfO 2 Powder, its purity is 99.9wt%, and average particle diameter is 80nm, weighs 13.1g boron carbide (B 4 C) powder, the purity is 97wt%, and the average particle size is 1.5 μm. Put the two powders together into a ball mill jar, add absolute ethanol, add zirconia ball milling media, and ball mill for 24 hours. Move the mixed mixture to In a vessel containing 300ml of absolute ethanol, disperse by ultrasonic oscillation for 0.5h;

[0043] (2) Weigh 22.5g of sucrose and add it to 200ml of water, stir to make it evenly mixed, then add it to the solution obtained in step (1), and heat it with magnetic stirring at the same time. uniform reactants;

[0044] (3) Put the reactant obtained in step (2) into a graphite crucible, and then put the graphite crucible into a high-purity argon-protected heat treatment furnace for heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com