Method for preparing Sb2S3-base organic and inorganic composite solar cell

A solar cell and inorganic composite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor order and stability of one-dimensional nanostructures, and achieve the effects of good optical stability, low energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A Sb-based 2 S 3 A method for preparing an organic-inorganic composite solar cell, comprising the steps of:

[0033] a. At room temperature, weigh 1.0g of titanium tetrachloride and dissolve it in absolute ethanol to obtain a mixed solution, wherein the molar ratio of titanium tetrachloride to absolute ethanol is 1:50, and add 0.4836 g of F127, then add 1.92ml concentrated hydrochloric acid to adjust the pH value of the mixed solution, and mix well to obtain a clear solution;

[0034] b. Put the FTO glass after ultrasonic cleaning into the spin coating machine, fix the FTO glass, start the spin coating machine, the spin coating speed is 4000rpm, the relative humidity in the spin coating machine is 10%, and TiO is obtained after repeated coating 5 times 2 / FTO coated glass;

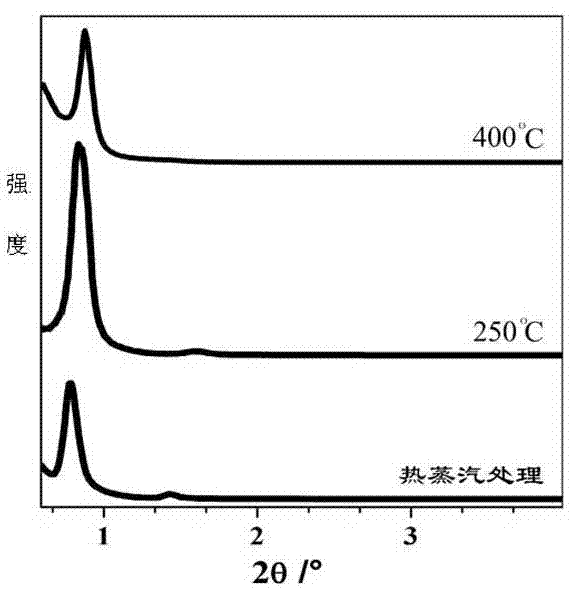

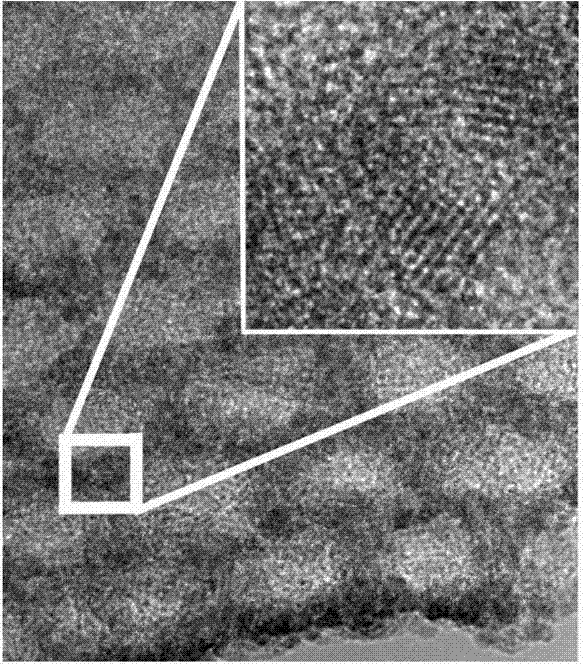

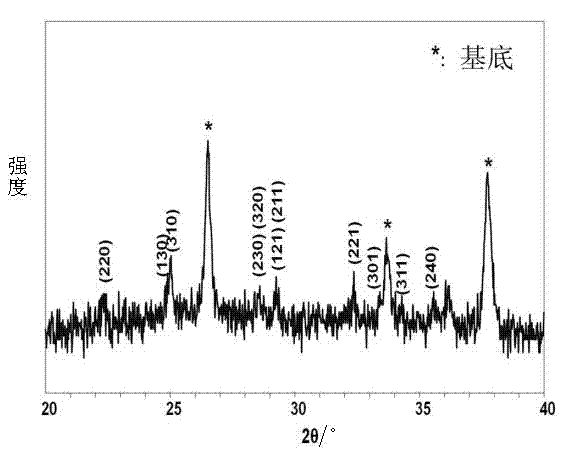

[0035] c. TiO 2 / FTO coated glass was dried at 100°C for 2h, and the dried TiO 2 / FTO coated glass is placed in hot steam at 120°C for crystallization reaction for 36 hours. After the crystalli...

Embodiment 2

[0045] A Sb-based 2 S 3 A method for preparing an organic-inorganic composite solar cell, comprising the steps of:

[0046] a. At room temperature, weigh 1.0g of titanium tetrachloride and dissolve it in absolute ethanol to obtain a mixed solution, wherein the molar ratio of titanium tetrachloride to absolute ethanol is 1:100, and add 0.2365 g P123, then add 1.92ml of concentrated hydrochloric acid to adjust the pH value of the mixed solution, mix well to obtain a clear solution;

[0047] b. Put the FTO glass after ultrasonic cleaning into the spin coating machine, fix the FTO glass, start the spin coating machine, the spin coating speed is 4000rpm, the relative humidity in the spin coating machine is 10%, and TiO is obtained after repeated coating 5 times 2 / FTO coated glass;

[0048] c. TiO 2 / FTO coated glass was dried at 120°C for 4h, and the dried TiO 2 / FTO coated glass is placed in hot steam at 150°C for crystallization reaction for 48 hours. After the crystallizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Photoelectric conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com