Column quinone positive pole material for lithium ion battery and application thereof

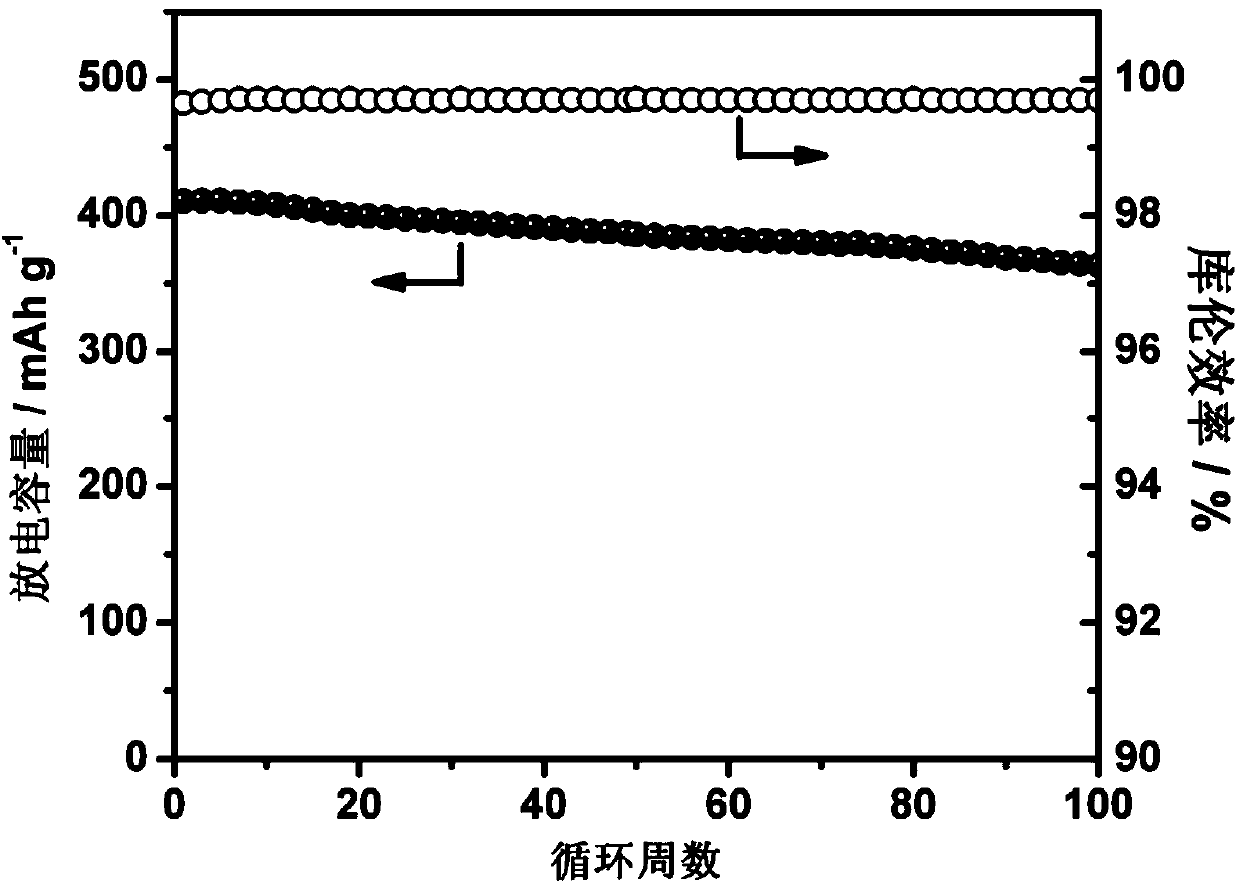

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc., can solve the problems of low actual capacity and low theoretical capacity, and achieve high specific capacity, high carbonyl utilization rate, and discharge specific capacity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

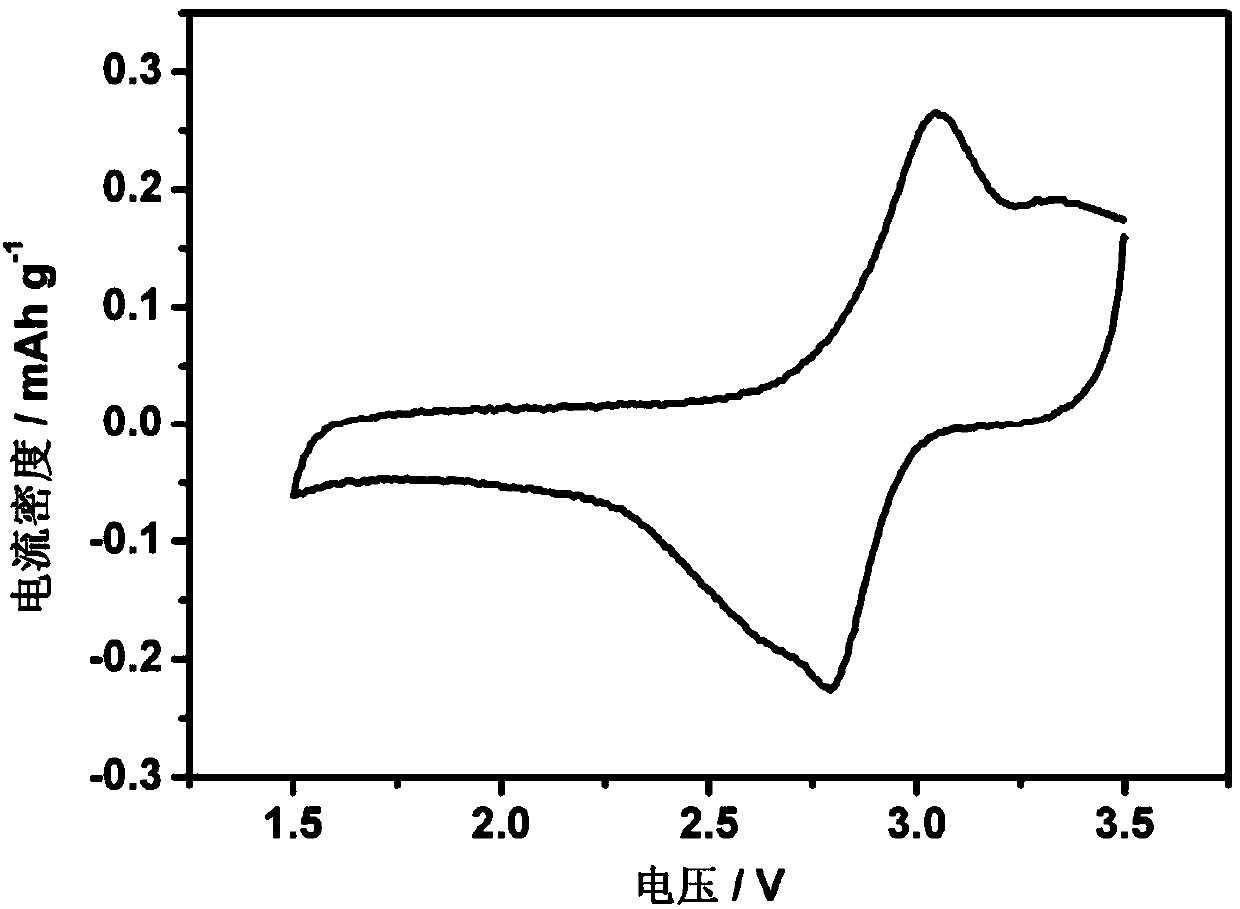

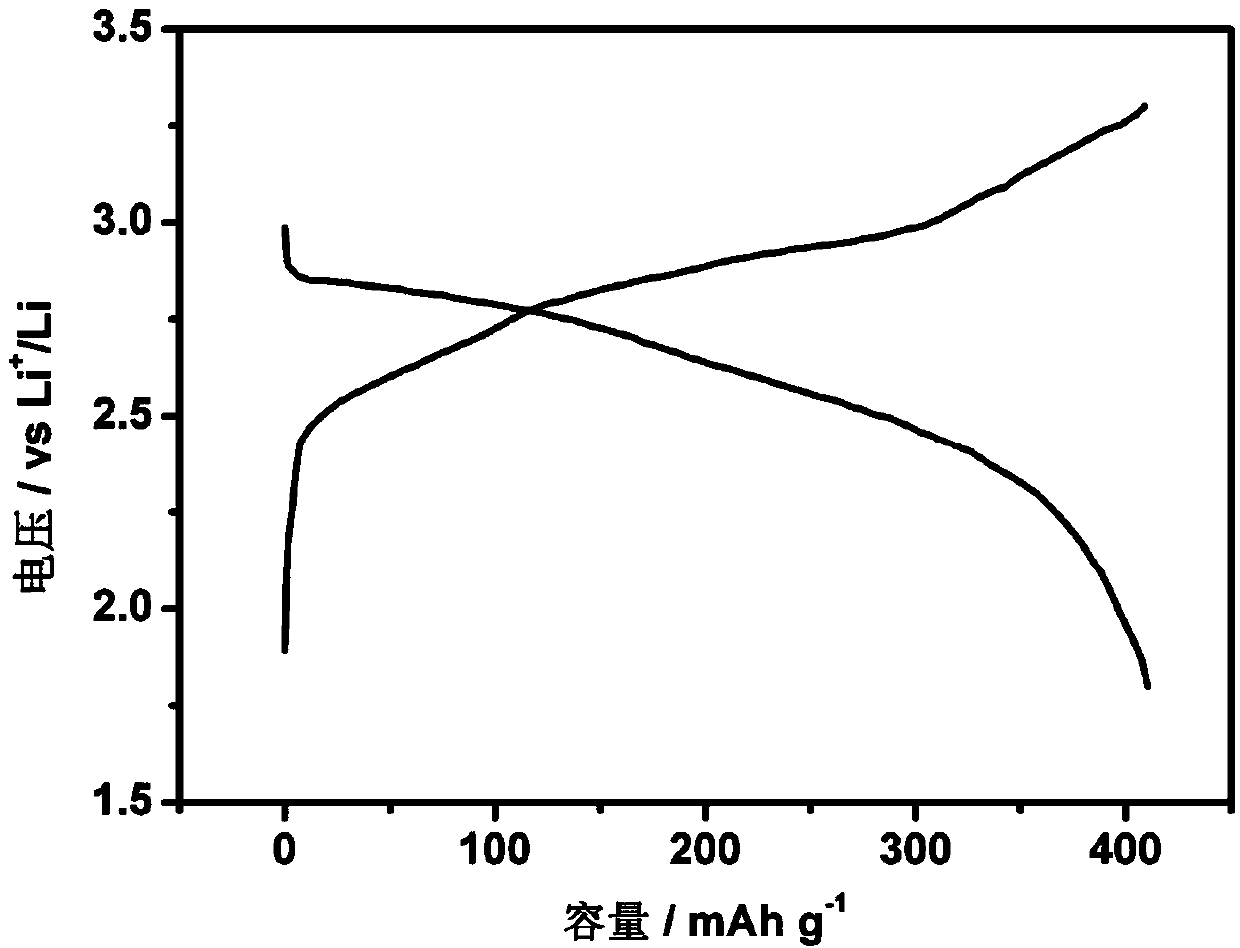

[0023] A pillar quinone positive electrode material for lithium-ion batteries, which is a ring formed by 5 p-benzoquinone units connected by methylene groups at the para-position, with the carbonyl group of the p-benzoquinone unit as the electrochemical redox reaction site. Like compound column [5] quinone, its general structural formula is as shown in general formula 1:

[0024]

[0025] Formula 1

[0026] In Formula 1, n=5.

[0027] The application of the pillar quinone positive electrode material for lithium-ion batteries is used to prepare quasi-solid-state lithium-ion batteries, and the method is as follows:

[0028] 1) Grind 12 mg of the active material column [5] quinone composed of 5 p-benzoquinone units, 6 mg of conductive carbon black and 2 mg of polyvinylidene fluoride binder in 100 μL of N-methylpyrrolidone organic solvent, and grind it into a slurry Evenly coated on the aluminum foil current collector, and then dried in -1MPa air at 353K for 10 hours to make ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com