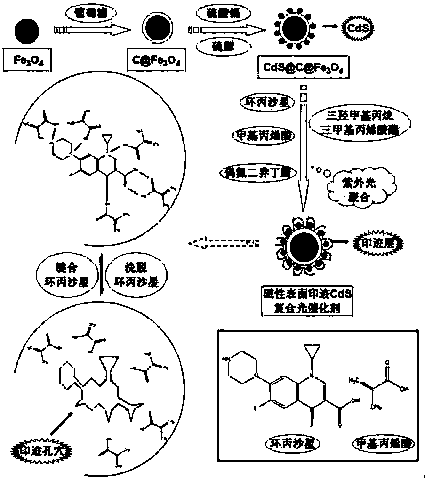

Preparation method of surface imprinting CdS compound photocatalyst based on magnetic carbon material

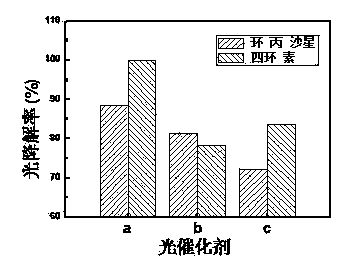

A technology of surface imprinting and composite light, which is applied in the direction of organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of secondary pollution and low efficiency, and achieve high Selectivity, convenient separation and recovery, and good photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: (1) Fe 3 o 4 Preparation of nanospheres: Add 1.35g of ferric chloride hexahydrate and 3.6g of sodium acetate into a beaker containing 50mL of ethylene glycol, stir magnetically until the mixture is evenly dispersed, then transfer the yellow solution to an autoclave, React at 200°C for 8 hours, then take out the autoclave, cool to room temperature, rinse the obtained black magnetic particles with absolute ethanol for 5 times, recover the black magnetic particles with a magnet, and dry them in vacuum at 30°C to obtain Fe 3 o 4 nanospheres.

[0041] (2) CFe 3 o 4 Preparation: 0.5g of Fe 3 o 4 , 4.0g of glucose and 1g of PEG were dissolved in a beaker containing 50ml of distilled water. After ultrasonication for 1.5h, the above solution was transferred to a 100ml reactor and reacted at 160°C for 12h. After that, the reactor was taken out, cooled to room temperature, and washed with distilled water Wash with ethanol at least three times, use a magnet to re...

Embodiment 2

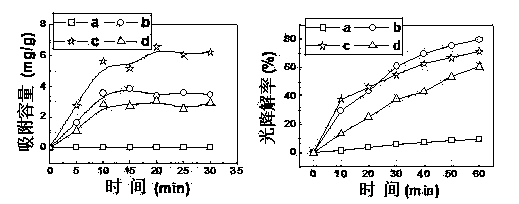

[0049] Example 2: Follow the same steps of the preparation process in Example 1, except that in step (5), the ratio of ciprofloxacin to methacrylic acid is five groups of different ratios, 1:1, 1:2, 1:4, 1 : 6, 1: 8, to prepare different magnetic surface imprinted CdS composite photocatalysts, investigate the impact of different ciprofloxacin and methacrylic acid ratios on the magnetic surface imprinted CdS composite photocatalyst photocatalytic activity, according to Example 1 (8) Steps to investigate the activity of photodegradation of ciprofloxacin antibiotic wastewater. The photocatalytic effect is as figure 2 As shown, it can be seen that the magnetic surface imprinted CdS composite photocatalyst prepared with a ratio of 1:6 has the best photodegradation effect on ciprofloxacin antibiotic wastewater. Under 60 minutes of visible light irradiation, the degradation of ciprofloxacin The rate can reach 62.29%.

Embodiment 3

[0050]Example 3: Carry out the same steps as the preparation process of Example 1, except that in step (5), five groups of different times of 0.5h, 1h, 2h, 3h, and 4h are used for the polymerization time of ultraviolet light irradiation to prepare different magnetic surface imprints CdS composite photocatalyst, investigate the effect of different ultraviolet light irradiation polymerization time on the photocatalytic activity of magnetic surface imprinted CdS composite photocatalyst, according to the steps in Example 1 (8) to investigate the activity of photodegradation of ciprofloxacin antibiotic wastewater. The experimental results show that the magnetic surface imprinted CdS composite photocatalyst prepared by ultraviolet light irradiation for 2 hours has the best photodegradation effect on ciprofloxacin antibiotic wastewater. Under 60 minutes of visible light irradiation, the degradation rate of ciprofloxacin It can reach 66.52%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com