High-temperature resistant antistatic artificial synthetic stone and manufacturing process thereof

An artificial synthetic stone, anti-static technology, applied in the direction of synthetic resin layered products, lamination, layered products, etc., can solve the anti-static synthetic stone high-density tool wear, anti-static synthetic stone thermal deformation, high temperature resistance. To the requirements and other issues, to achieve the effect of reducing the friction coefficient, improving heat resistance, excellent high temperature resistance and moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

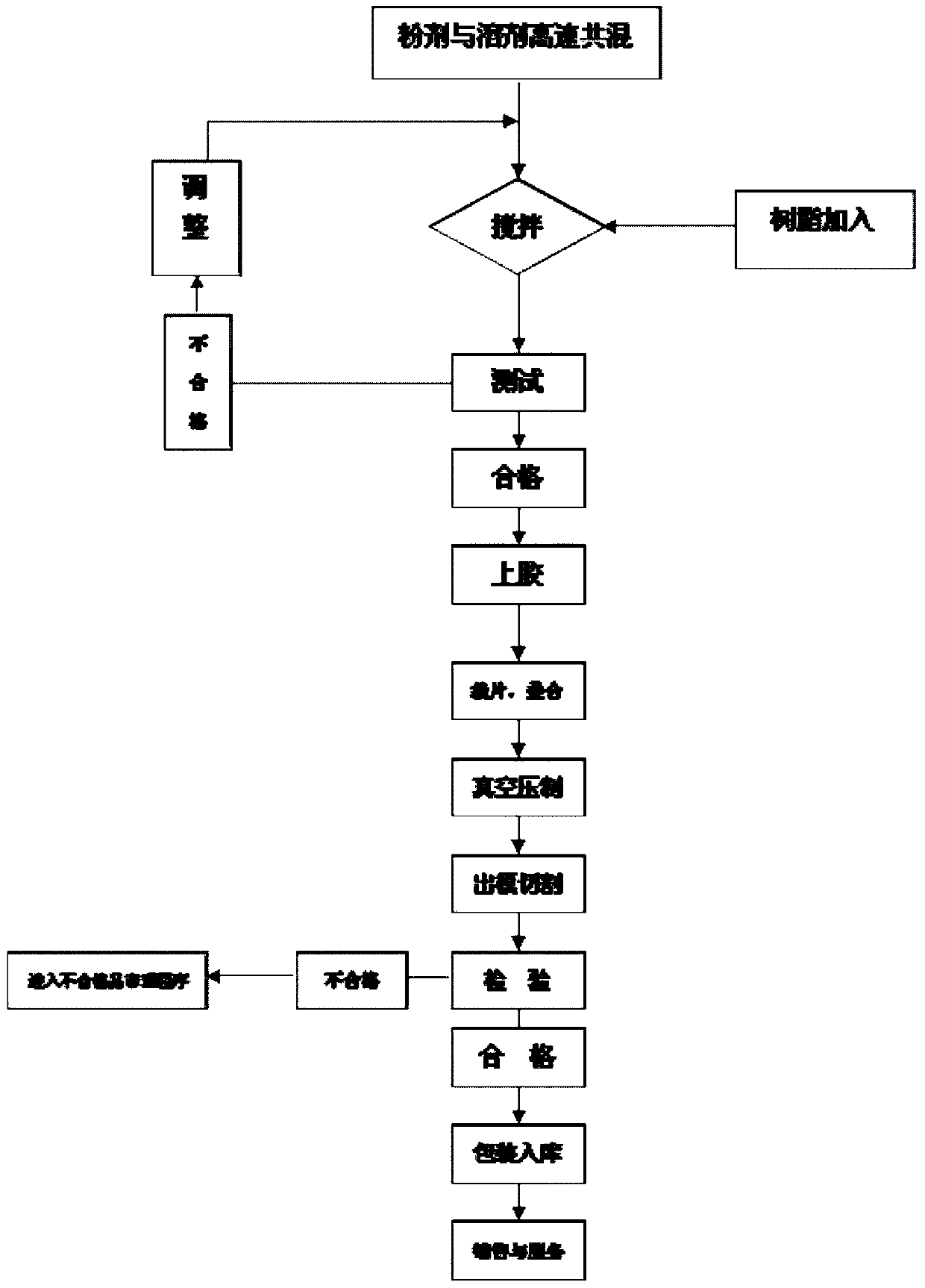

Method used

Image

Examples

Embodiment 1

[0023] A production method for making full use of new materials and combinations of new materials to produce new antistatic artificial synthetic stones, especially related to antistatic graphite fiberglass cloth, graphite fiberglass felt, inorganic nanomaterials, polyimide resin, Novolak The first application of type epoxy resin and hollow glass microspheres in the field of antistatic artificial synthetic stone. The amount of the inorganic nano material silicon dioxide is 3%, the amount of hollow glass microspheres is 5%, the amount of conductive carbon black is 1.5%, the amount of polyimide resin (solid content) is 24%, Novolak type epoxy The amount of resin (solid content) is 22%, bisphenol A type epoxy resin (solid content) is 35%, to form a glue solution. The amount of antistatic graphite fiberglass cloth and graphite fiberglass felt is 52% of the above glue (solid content). (Others can be filled with silica powder)

[0024] Put inorganic nanomaterials silica, hollow gla...

Embodiment 2

[0031] A production method for making full use of new materials and combinations of new materials to produce new antistatic artificial synthetic stones, especially related to antistatic graphite fiberglass cloth, graphite fiberglass felt, inorganic nanomaterials, polyimide resin, Novolak The first application of type epoxy resin and hollow glass microspheres in the field of antistatic artificial synthetic stone. The amount of the inorganic nanomaterial silicon dioxide is 2%, the amount of hollow glass microspheres is 4%, the amount of conductive carbon black is 1%, the amount of polyimide resin (solid content) is 23%, and the amount of Novolak type epoxy The amount of resin (solid content) is 20%, bisphenol A epoxy resin (solid content) is 40%, and the glue is formed. The amount of antistatic graphite fiberglass cloth and graphite fiberglass felt is 50% of the above glue (solid content). (Others can be filled with silica powder)

[0032] Put inorganic nanomaterials silica, h...

Embodiment 3

[0039] A production method for making full use of new materials and combinations of new materials to produce new antistatic artificial synthetic stones, especially related to antistatic graphite fiberglass cloth, graphite fiberglass felt, inorganic nanomaterials, polyimide resin, Novolak The first application of type epoxy resin and hollow glass microspheres in the field of antistatic artificial synthetic stone. The amount of the inorganic nanomaterial silicon dioxide is 3%, the amount of hollow glass microspheres is 8%, the amount of conductive carbon black is 3%, the amount of polyimide resin (solid content) is 25%, and the amount of Novolak type epoxy The amount of resin (solid content) is 20%, bisphenol A type epoxy resin (solid content) is 50%, and the glue is formed. The amount of antistatic graphite fiberglass cloth and graphite fiberglass felt is 40% of the above glue (solid content). (Others can be filled with silica powder)

[0040] Put inorganic nanomaterials sili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com