Unsaturated aliphatic-polylactic acid segmented copolymer and preparation method thereof

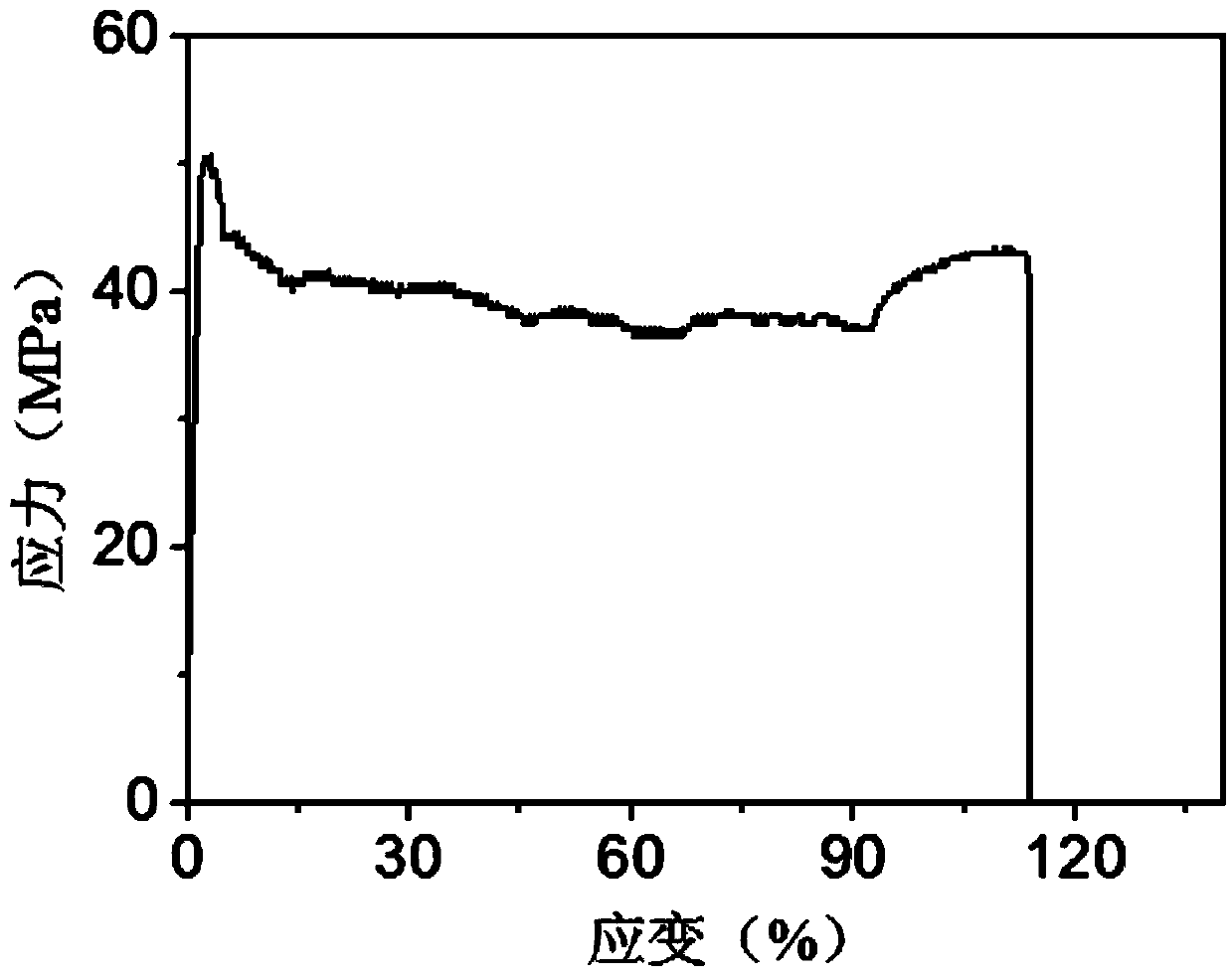

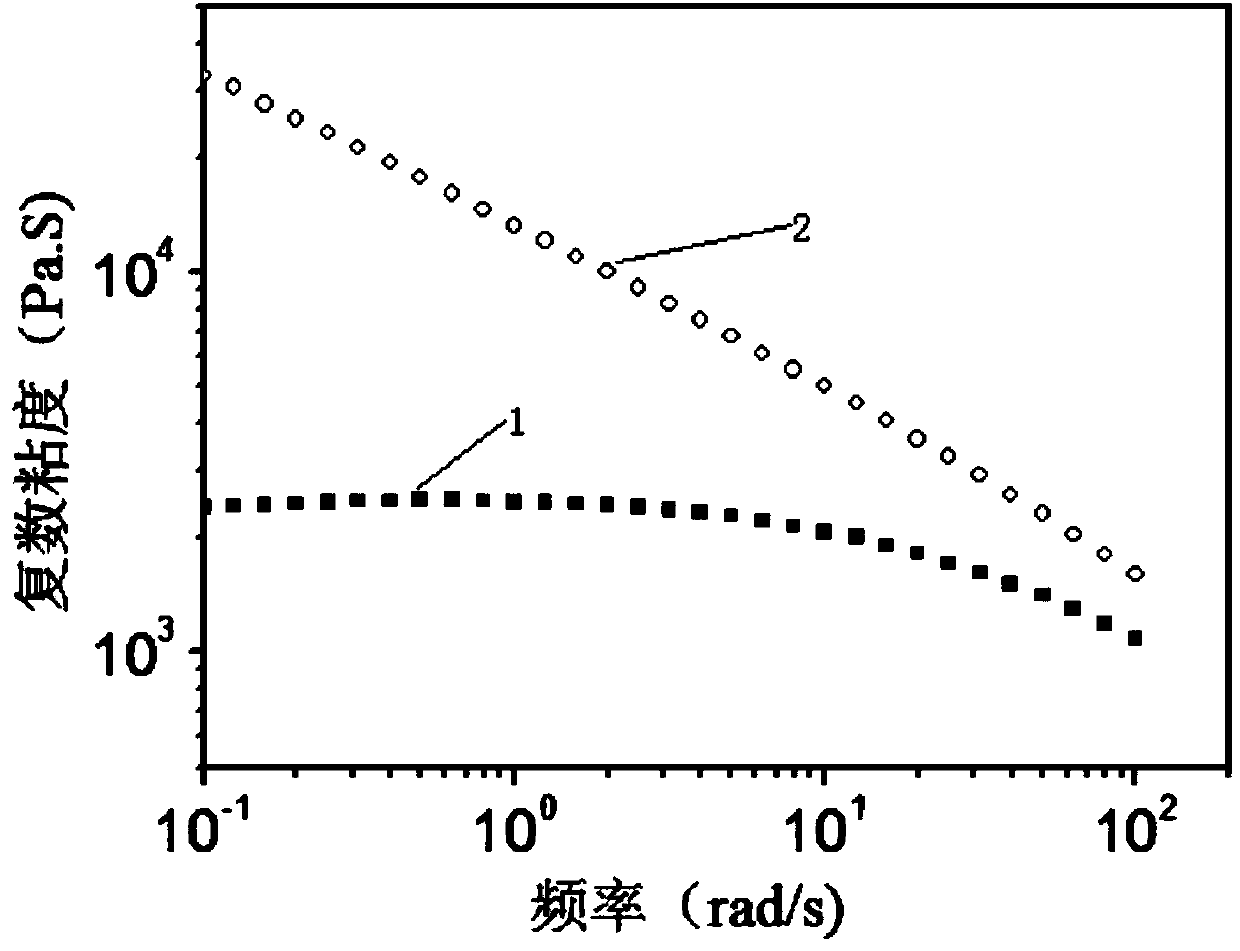

A technology of block copolymer and aliphatic polyester, which is applied in the field of unsaturated aliphatic-polylactic acid block copolymer and its preparation, can solve the problems that the elongation at break can only reach 60% and poor mechanical properties, etc. Achieve good mechanical properties, reduce brittleness, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a kind of preparation method of unsaturated aliphatic-polylactic acid block copolymer, comprises the following steps:

[0050]a) performing esterification reaction and polycondensation reaction on saturated dicarboxylic acid compound, saturated dihydric alcohol compound and unsaturated compound to obtain unsaturated aliphatic polyester in molten state;

[0051] The saturated dicarboxylic acid compound is one or more of saturated dicarboxylic acids and saturated dicarboxylic acid derivatives;

[0052] The unsaturated compound is a dibasic carboxylic acid compound containing a double bond or a dibasic alcohol compound containing a double bond;

[0053] b) Under an oxygen-free environment, the molten unsaturated aliphatic polyester and lactide obtained in step a) are polymerized to obtain unsaturated aliphatic-polylactic acid having a structure shown in formula (I) block copolymers;

[0054]

[0055] In formula (I), m=5~200, n=5~200, p=10~500; ...

Embodiment 1

[0111] The 2L reaction kettle with four vents was repeatedly evacuated and nitrogen-filled to cool, and then 400g of succinic acid, 600g of butanediol, 312g of maleic anhydride and 0.7g of tetrabutyl titanate were mixed with nitrogen. After the esters are added to the reaction kettle in turn, the temperature of the reaction kettle is raised to 140°C and the reactants are stirred, and the water generated by the reaction is collected at the same time. When the temperature of the system reaches 210° C., the pressure is gradually reduced to a high vacuum state. When the pressure is 250 Pa, the polycondensation reaction is carried out for 3 hours to obtain polybutylene succinate-butylene maleate in a molten state.

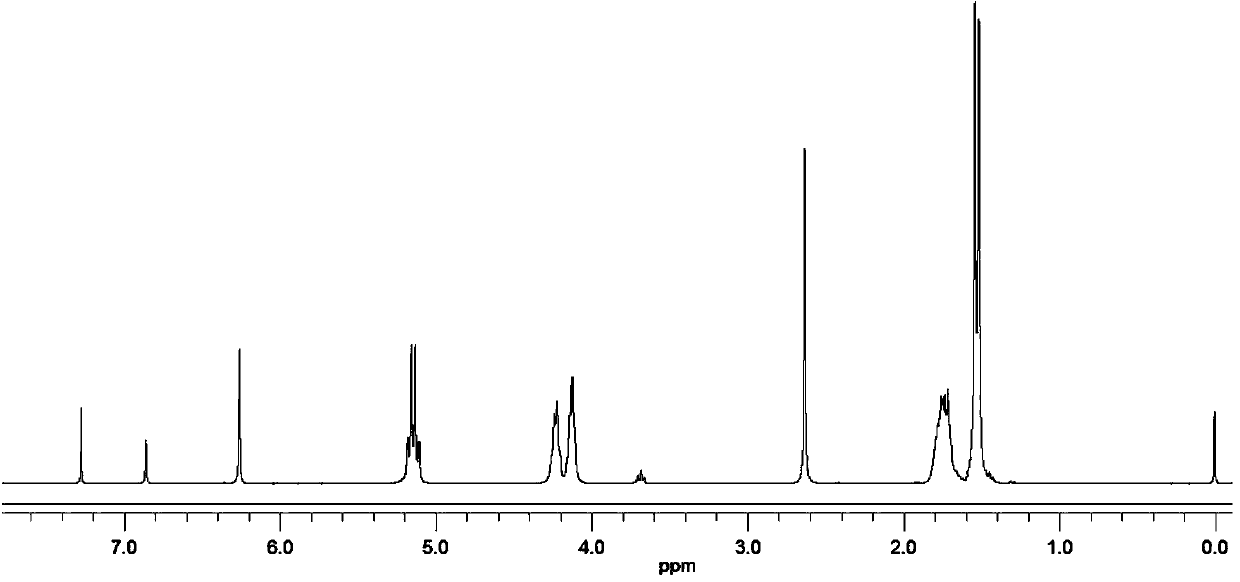

[0112] The present invention carries out gel permeation chromatography analysis to the obtained copolymer according to the test technical scheme described in the above-mentioned technical scheme, and the relative number-average molecular weight of the obtained polybutyle...

Embodiment 2

[0120] Get polybutylene succinate-butylene maleate copolymer 100g in embodiment 1, add the dry lactide of 200g and 0.2g stannous octoate (Sn(Otc) wherein 2 ), and then react the obtained mixture at 120°C, the reaction is shown in formula (a), this reaction adopts bulk polymerization, after 8h, the temperature is raised to 180°C, the unreacted monomer is removed by vacuuming, and the pressure is 250Pa, to obtain Melted polybutylene succinate-butylene maleate-polylactic acid block copolymer.

[0121]

[0122] In formula (a), m=5-200, n=5-200, p=10-500.

[0123] The present invention carries out gel permeation chromatography analysis to the obtained copolymer according to the test technical scheme described in the above technical scheme, and the obtained molten polybutylene succinate-butylene maleate-polylactic acid embedding The relative number average molecular weight of the segment copolymer was 23.0 kg / mol, and the relative molecular weight distribution was 1.58.

[0124...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative number average molecular weight | aaaaa | aaaaa |

| Relative number average molecular weight | aaaaa | aaaaa |

| Relative number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com