Atmospheric pressure cold plasma modifying method for plant fiber and application of modifying method in wood-plastic composite material

A technology of wood-plastic composite materials and cold plasma, which is applied in the field of plant fibers and composite materials, can solve the problems of affecting the dimensional stability and durability of materials, affecting the interface bonding force of materials, and the decline of mechanical properties of materials, and achieve surface roughness Increased free energy, increased surface free radicals, and good interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

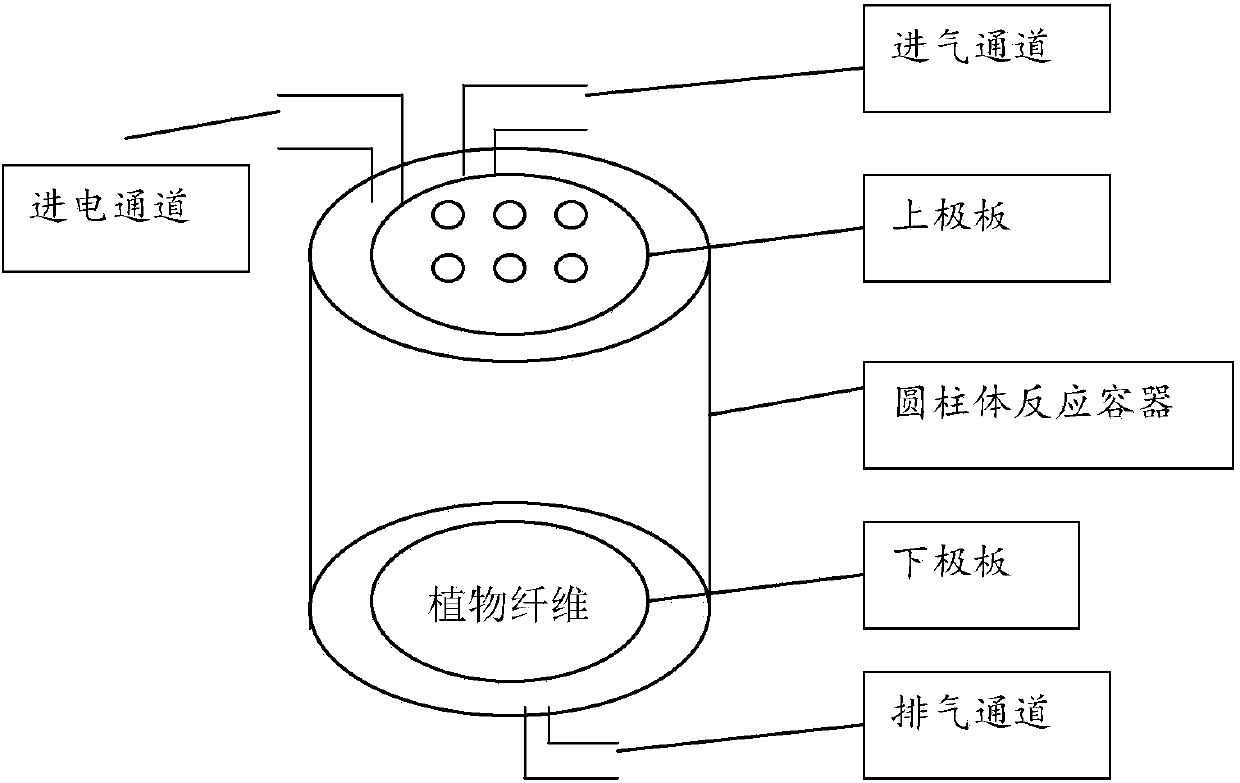

Method used

Image

Examples

Embodiment 1

[0030] Place the wood powder (with an average particle size of 50 mesh) in an oven at 100°C for 8 hours to dry to obtain wood powder with a moisture content of 3% and an average particle size of 50 mesh. The wood flour was treated with atmospheric pressure cooled plasma, the reaction gas was argon, the gas flow rate was 15 L / min, the processing power was 600 W, the processing voltage was 5000 V, the processing distance was 15 mm, and the processing time was 5 min. wood flour. Commercially available high-density polyethylene (model DMDA-8008, density 0.95 g / cm 3 , melting point is 135°C, melt index is 6.5 g / 10min) 100 parts, lubricant (stearic acid and calcium stearate mixed at a ratio of 1:1) 1 part, 50 parts of the above-mentioned modified wood flour are put into high-speed mixing In the machine, after mixing for 20 minutes, cool and unload, make a premix and then extrude and granulate. The granulation temperature is 165°C and the granulation time is 20 minutes to obtain woo...

Embodiment 2

[0032] Bamboo powder (with an average particle size of 50 mesh) was placed in an oven at 105°C and dried for 8 hours to obtain bamboo powder with a moisture content of 3% and an average particle size of 50 mesh. Bamboo powder was treated with atmospheric pressure cooled plasma, the reaction gas was a mixture of argon and nitrogen with a volume ratio of 1:1, the gas flow rates of argon and nitrogen were 10 L / min and 1 L / min, respectively, and the processing power was 600 W , the treatment voltage was 5500 V, the treatment distance was 15 mm, and the treatment time was 6 minutes to obtain modified bamboo powder. Commercially available polypropylene (model K8303, density 0.90 g / cm 3 , melting point is 168°C, melt index is 3.2 g / 10min) 100 parts, lubricant (stearic acid and calcium stearate mixed at a ratio of 1:1) 1.5 parts, modified bamboo powder 80 parts into the high-speed mixer In the process, after mixing for 25 minutes, cool and unload, make a premix and then extrude and g...

Embodiment 3

[0034] The rice husk powder (with an average particle size of 80 mesh) was placed in an oven at 105°C and dried for 9 hours to obtain rice husk powder with a moisture content of 2% and an average particle size of 80 mesh. Atmospheric pressure-cooled plasma was used to treat wood powder, the reaction gas was a mixture of argon and acetylene (volume ratio 1:5), the gas flow rates of argon and acetylene were 12 L / min and 1 L / min, respectively, and the processing power was 600 W, the processing voltage was 6000 V, the processing distance was 15 mm, and the processing time was 8 min to obtain modified rice husk powder. Commercially available high-density polyethylene (model DMDA-8008, density 0.95g / cm 3 , with a melting point of 135°C and a melt index of 6.5 g / 10min), 100 parts, 3 parts of lubricant (stearic acid and calcium stearate are mixed at a ratio of 1:1), 120 parts of modified rice husk powder, put into high speed In the mixer, after mixing for 30 minutes, cool and unload,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com