A kind of fluorocarbon two-component coating and its application

A two-component coating and fluorocarbon technology, applied in polyurea/polyurethane coatings, coatings, photovoltaic power generation, etc., can solve the problems of poor adhesion of fluorocarbon coatings, and achieve good weather resistance, low cost, and strong adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

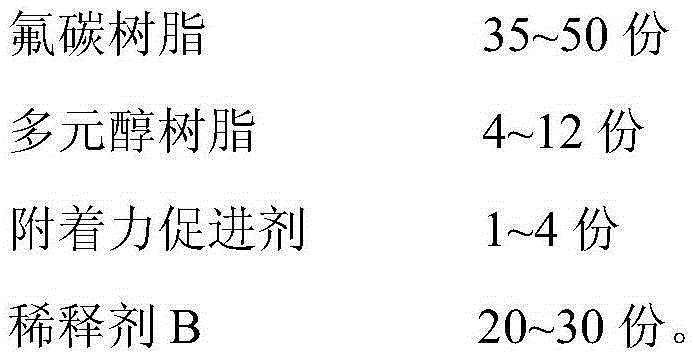

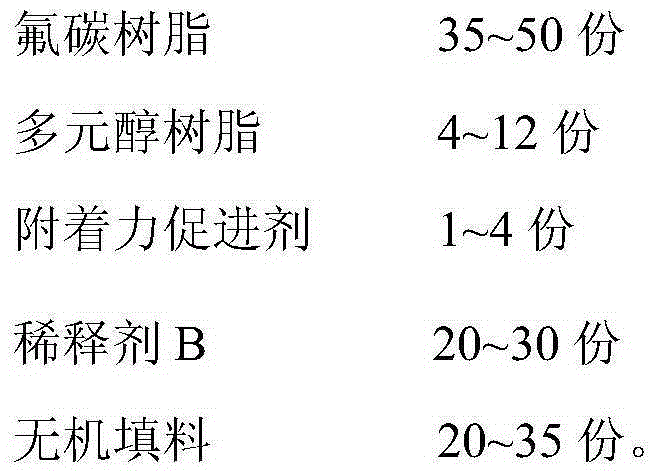

Method used

Image

Examples

Embodiment 1

[0052] In terms of parts by mass, 50g of isophorone diisocyanate (IPDI) trimer (NCO content is 37.5%, mass percentage, Bayer, Germany) was mixed with 20g xylene (Hangzhou Chemical Reagent Co., Ltd.) and 30g butyl acetate Esters (Hangzhou Chemical Reagent Co., Ltd.) were mixed evenly, and filtered to obtain 100g of component A, in which the molar content of NCO was 4.46mmol / g; 25g of methyl ethyl ketone (Hangzhou Chemical Reagent Co., Ltd.) Add 40g chlorotrifluoroethylene type fluorocarbon resin (FEVE) JF-2XA (hydroxyl value 25mgKOH / g, Changshu Sanai Fuzhonghao Material Co., Ltd.), 8g polyester polyol DESMOPHEN1652 (Germany Bayer company), 1g adhesion promotion Agent ADK (Hemmings Dechem Company), 0.01g catalyst zinc isooctanoate (Taixing Shengling Co., Ltd.), 0.69g wetting and dispersing agent BYK-163 (Germany BAK Chemical Co., Ltd.), 24g titanium dioxide (Shanghai Hongyun Yuan Chemical Co., Ltd.), 1g of carbon black (Dongguan Jutai Chemical Co., Ltd.), pre-dispersed and then ...

Embodiment 2

[0055] In terms of parts by mass, 60g of hexamethylene diisocyanate (HDI) trimer (NCO content of 19.6%, Wanhua Chemical Group Co., Ltd.) and 40g of toluene (Hangzhou Chemical Reagent Co., Ltd.) were mixed evenly, filtered, Obtain 100g of component A, in which the molar content of NCO is 2.8mmol / g; put 20g of xylene (Hangzhou Chemical Reagent Co., Ltd.) in a container, and add 41g of tetrafluoroethylene type fluorocarbon resin (FEVE) GK570 sequentially under low-speed stirring (Hydroxyl value 60mgKOH / g, Daikin Corporation of Japan), 4g polyester polyol DESMOPHEN1150 (Bayer, Germany), 3g adhesion promoter ADK (Hemmings Deqian Company), 0.02g catalyst dibutyltin dilaurate ( Taixing Shengling Co., Ltd.), 1.68g wetting and dispersing agent BYK-163 (Germany BAK Chemical Co., Ltd.), 25g titanium dioxide (Shanghai Hongyunyuan Chemical Co., Ltd.), 3g nano-silica (Shouguang Baote Chemical Co., Ltd. Company), 2g carbon black (Dongguan Jutai Chemical Co., Ltd.), after pre-dispersion, grin...

Embodiment 3

[0058] In terms of parts by mass, 50g of hexamethylene diisocyanate (HDI) biuret (NCO content of 16.5%, Bayer, Germany) and 50g of butyl acetate (Guangzhou Tongbang Chemical Co., Ltd.) were mixed evenly, and filtered to obtain 100g of component A, in which the molar content of NCO is 1.96mmol / g; put 25g of propylene glycol methyl ether acetate (PMA) (Kunshan Chengxin Chemical) in a container, and add 20g of chlorotrifluoroethylene type fluorocarbon resin in sequence under low-speed stirring (FEVE) JF-2XA (hydroxyl value 25mgKOH / g, Changshu Sanai Fuzhonghao Material Co., Ltd.) and 20g tetrafluoroethylene type fluorocarbon resin (FEVE) GK570 (hydroxyl value 60mgKOH / g, Japan Daikin Company) Compound, 6g polyester polyol DESMOPHEN2200B (Bayer, Germany), 4g adhesion promoter ADK (Hemmings Deqian Company), 0.1g catalyst zinc isooctanoate (Taixing Shengling Co., Ltd.), 1.6g wetting and dispersing Agent BYK-9010 (Germany BAK Chemical Co., Ltd.), 15g titanium dioxide (Shanghai Hongyuny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com