Paclitaxel purifying method of paclitaxel crude product produced by Chinese yew cell culture

A technology of yew cells and paclitaxel, which is applied in the direction of organic chemistry, can solve the problems of increasing the production cost of isolating paclitaxel, high price, and polluting the environment, and achieves good application prospects, reduced production costs, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

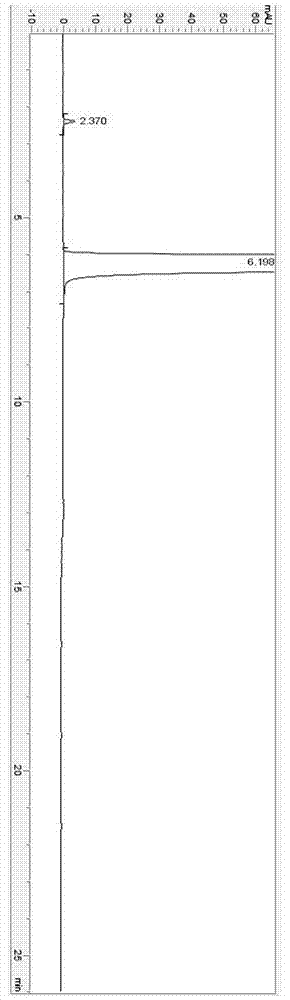

[0022] In a 150 mL single-necked flask, add paclitaxel crude product produced by Taxus chinensis cell culture (manufactured by a pharmaceutical company in Guangdong, in which paclitaxel content is 63.0%, cephalomannine and unknown substances are 1.74% and 3.56% respectively) 1.20 g, then add 18.9 mL of a more polar organic solvent-analytical grade propanol, so that the mass of paclitaxel g / propanol volume mL=0.04 g / mL, stir well until the sample is completely dissolved, and then slowly drop into the system Reverse organic solvent-2.10 mL of analytically pure pentane, make pentane:propanol=10:90 (volume ratio), stir well for 10 min; then add 2.63 mL of pentane dropwise, make pentane:propanol=20 : 80 (volume ratio), fully stirred for 10 min; 10.0% increasing rate gradually increased the volume content of pentane, slowly added dropwise until the solution in the single-necked flask appeared flocculent, fully stirred for more than 1.5 h; then remained at 10.0 % Gradually increase t...

Embodiment 2

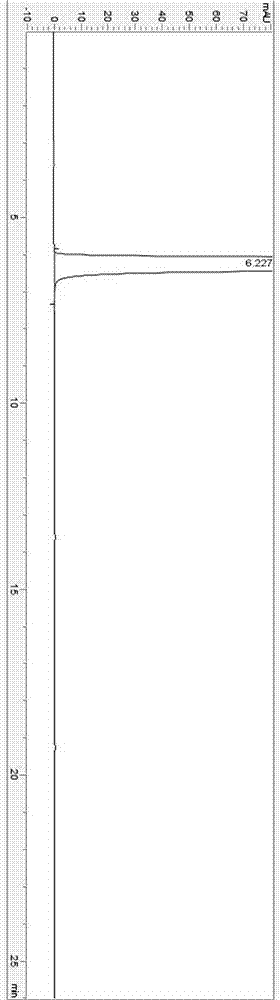

[0026] In a 100 mL single-necked flask, add paclitaxel crude product produced by yew cell culture (provided by a pharmaceutical company in Guangdong, in which paclitaxel content is 65.0%, cephalomannine and unknown substance content are 1.80% and 3.51%, respectively) 1.20 g, and then add 11.1 mL of a relatively polar organic solvent-analytical pure ethyl acetate, so that the paclitaxel mass g / ethyl acetate volume mL=0.07 g / mL, stir well until the sample is completely dissolved, and then slowly add to the system Slowly add 2.78 mL of reverse organic solvent-analytical grade n-hexane to make n-hexane:ethyl acetate=20:80 (volume ratio), and stir thoroughly for 10 min; then add 1.98 mL of n-hexane dropwise to make n-hexane: Ethyl acetate=30:70 (volume ratio), fully stir for 10 min; gradually increase the volume content of n-hexane at a rate of 10.0%, slowly add dropwise until flocs appear in the solution in the one-necked flask, fully stir for more than 1.5 h ; Then gradually incr...

Embodiment 3

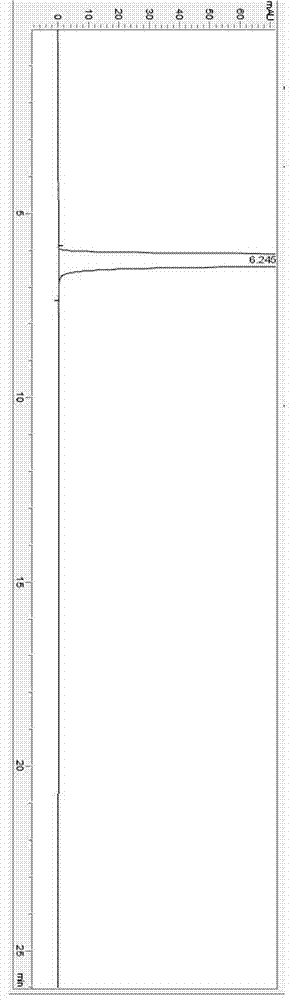

[0030] In a 100 mL single-necked flask, add paclitaxel crude product produced by yew cell culture (provided by a pharmaceutical company in Guangdong, in which paclitaxel content is 68.0%, cephalomannine and unknown substance content are 1.86% and 3.95%, respectively) 1.20 g, then add 8.16 mL of a more polar organic solvent-analytical pure dichloromethane, make paclitaxel mass g / dichloromethane volume mL=0.10 g / mL, stir well until the sample is completely dissolved, and then slowly add to the system Slowly add 3.50 mL of reverse organic solvent-analytical pure isooctane to make isooctane:dichloromethane=30:70 (volume ratio), and stir thoroughly for 10 min; then add 1.94 mL of isooctane dropwise to make Isooctane:dichloromethane=40:60 (volume ratio), fully stir for 10 min; gradually increase the volume content of isooctane at a rate of 10.0%, and slowly add it dropwise until flocs appear in the solution in the one-necked flask. Stir fully for more than 1.5 h; then gradually incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com