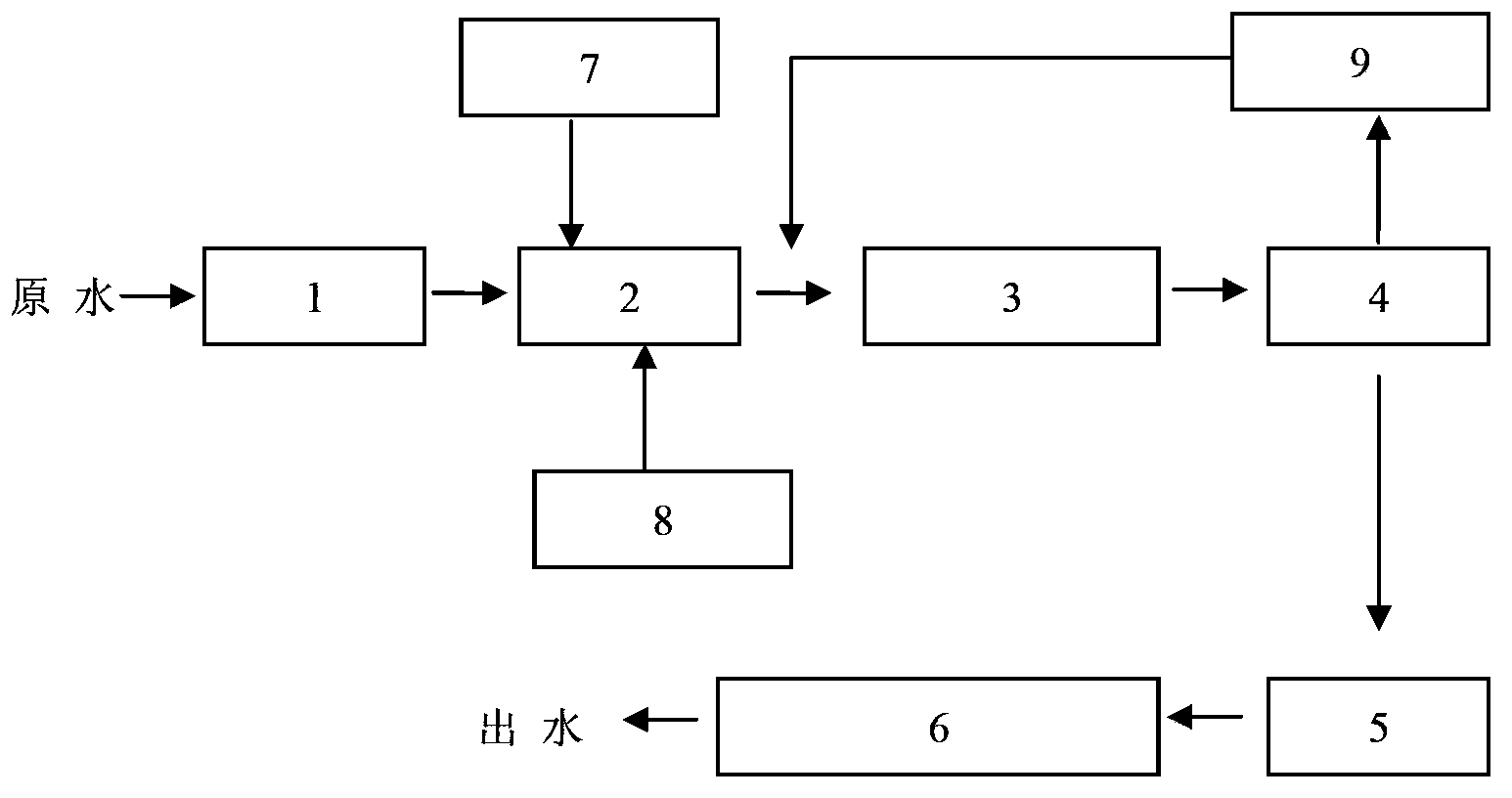

Chemical microwave treatment method of industrial methyldiethanolamine wastewater

A technology of methyldiethanolamine and microwave chemistry, applied in chemical instruments and methods, natural water treatment, water/sewage multi-stage treatment, etc., can solve the problems of ineffective wastewater treatment, difficult to degrade, high COD of wastewater, etc., and achieve faster The effect of flocculation and sedimentation speed and efficiency, promotion of degradation and improvement of removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Take 2000ml of raw water, measure its pH=9, COD Cr =1080mg / L, the water quality is slightly muddy.

[0061] Put 2000ml of raw water into the water tank, add 2ml of oxidizing agent sodium hypochlorite, turn on the mixer, stir evenly for 1 minute, and the measured pH drops to 7.

[0062] Take 1ml of the prepared diatomite and calcium oxide sensitizer suspension with a mass concentration of 5% and the mass concentration of diatomite and calcium oxide are both 2.5%, add it to the waste water, turn on the mixer, and stir evenly for 30 seconds , the measured pH rose to 11.

[0063] Take 1ml of the prepared polyferric sulfate coagulant solution, the concentration of which is 5%, add the mixed solution, turn on the mixer, stir evenly for 30 seconds, and the measured pH drops to 8.

[0064] Turn on the lifting small liquid pump, start the microwave equipment at the same time, introduce the mixed liquid into the microwave processing equipment, and the liquid will come out after...

Embodiment 2

[0069] Dilute the MDEA wastewater to be treated until the COD is around 1000mg / L.

[0070] Add a sodium hypochlorite solution with a concentration of 10% into the aeration box at a volume ratio of 1:1000, and simultaneously aerate the box to maintain a stable aerosol ratio and aeration time.

[0071] Introduce the waste water into the mixing tank, add 5% diatomite and calcium oxide mixed sensitizer solution to the waste water, its volume is 1 / 2000 of the waste water volume, add 5% polyferric sulfate mixed Coagulant solution, whose volume is 1 / 2000 of the waste water volume, continue to stir and mix until uniform, because the solution of the sensitizer itself is alkaline, and the solution of the coagulant itself is acidic, like this, the MDEA to be entered into the microwave reactor The pH of the wastewater is controlled to be neutral.

[0072] The mixed wastewater enters the microwave sensitization reactor with a microwave power of 1.6kW, and the wastewater stays there for 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com