Functionalized nanometer silica with ultraviolet ray absorption function group grafted on surface, and preparation method thereof

A technology of nano-silica and surface grafting, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, and fibrous fillers. It can solve the problems of easy loss, poor extraction resistance, and easy migration. Good dispersibility, solving intolerance to extraction, and improving the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

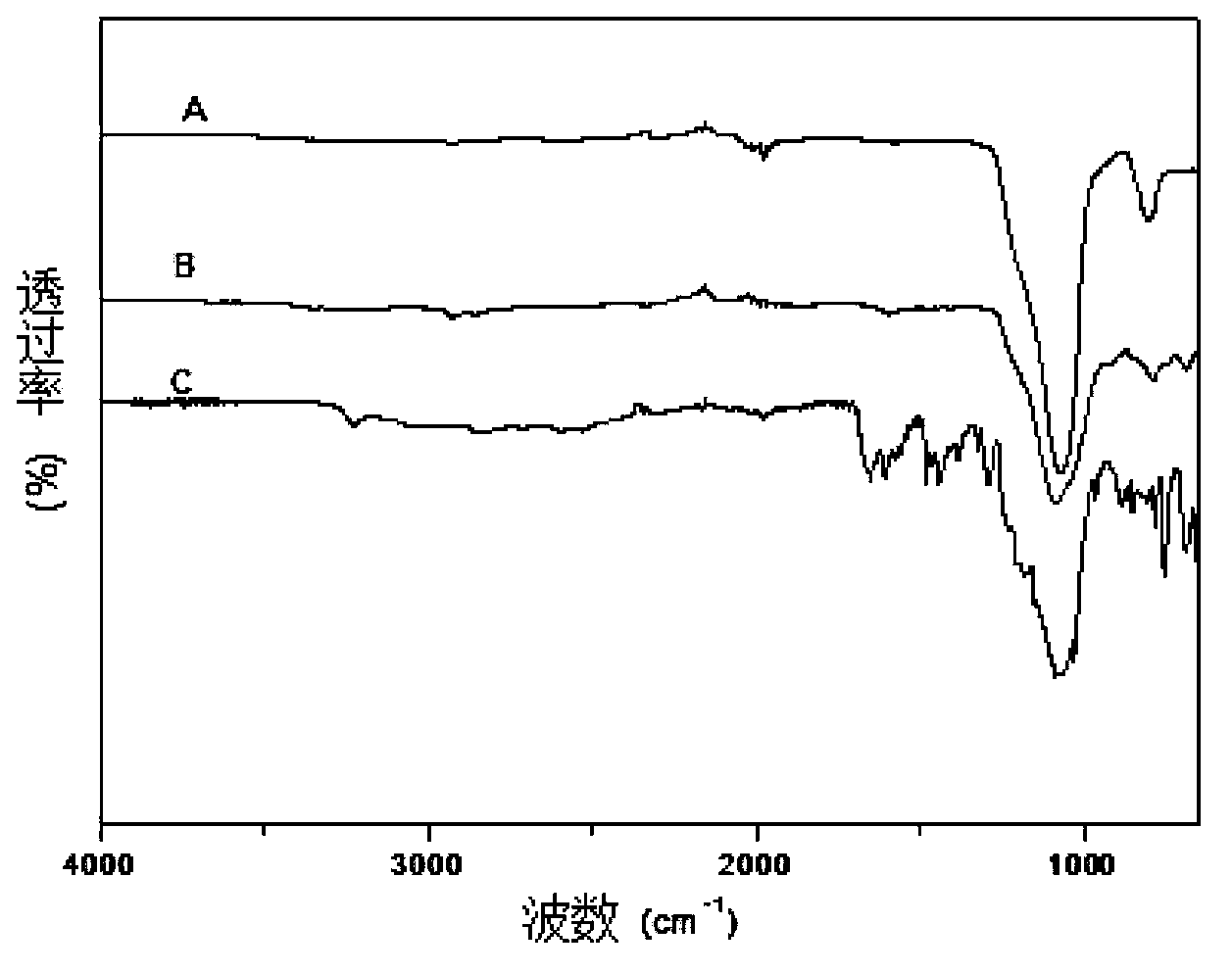

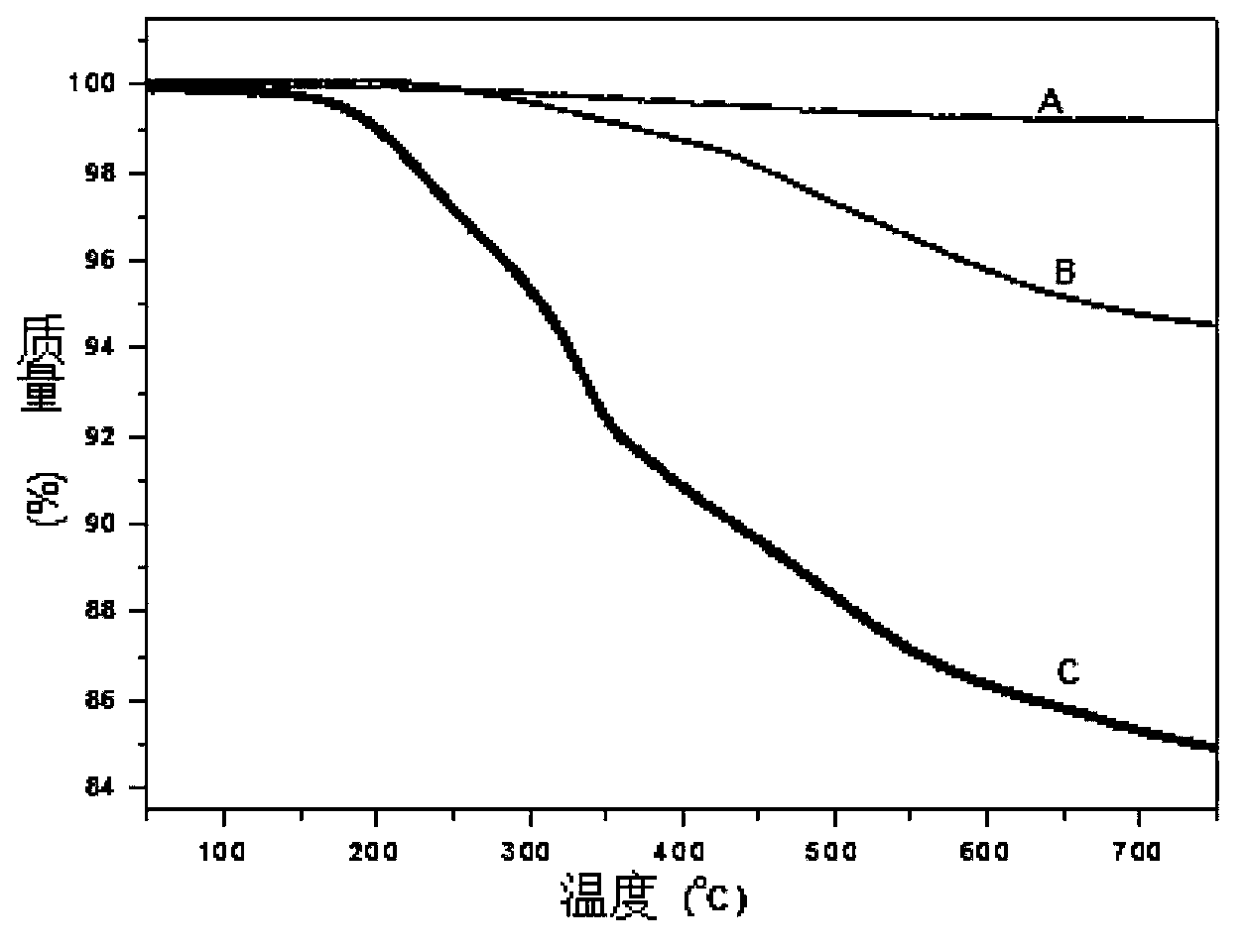

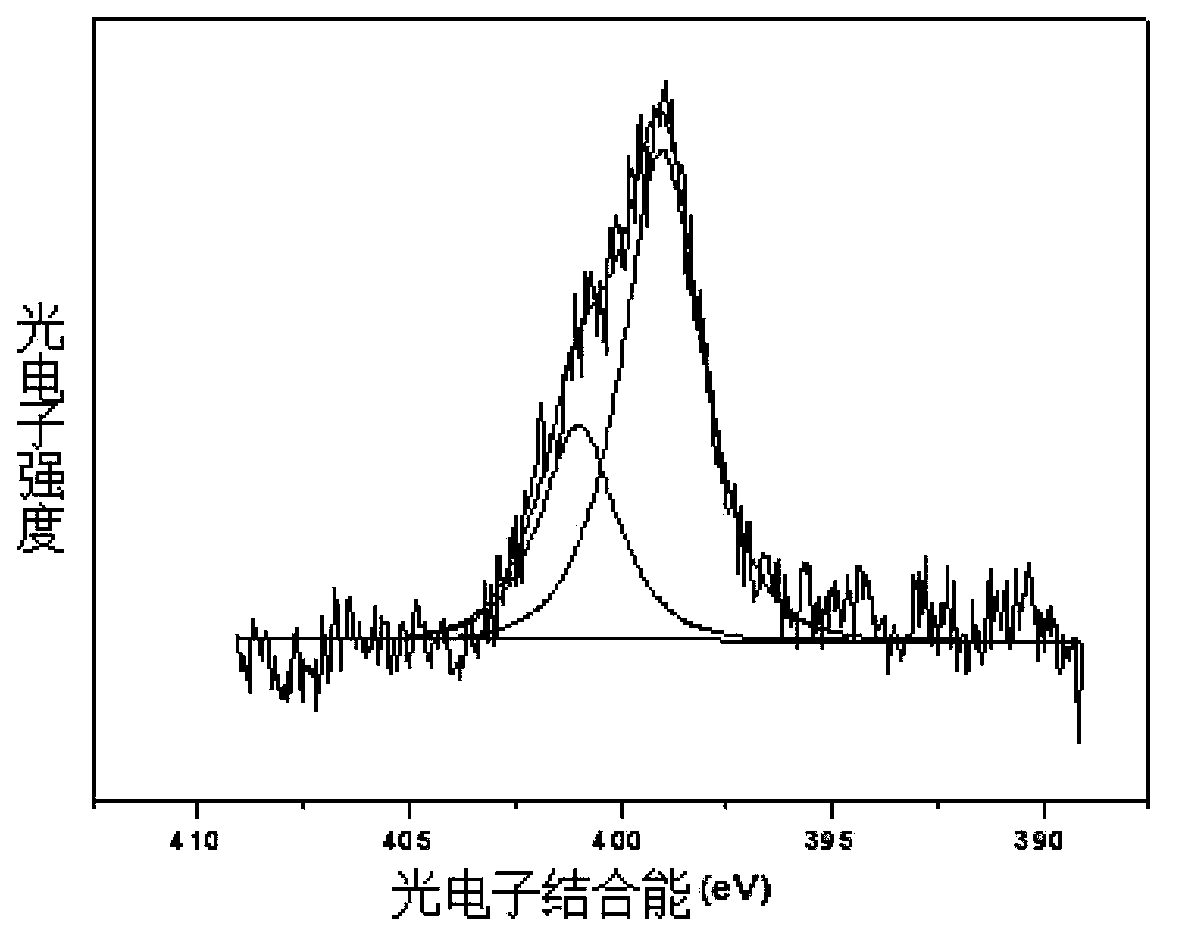

[0041] Aminosilane coupling agent chemical grafting treatment of nano-silica particles: Weigh 10 grams of nano-silica particles (A-200) and disperse them in about 150 ml of toluene and stir to form a stable suspension of silica particles; Then add 5 grams of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, heat, stir and react under toluene reflux for 24 hours and then filter, and the filter is washed three times with toluene and ethanol respectively. To remove the unreacted residue of N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane, the amount of solvent used for each washing is 150 ml. The washed nano-silica particles grafted with N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane were placed in a vacuum oven and dried at 100° C. for 6 hours. Depend on figure 1 B in figure 2 B in and Figure 3A It can be seen that N-(β-aminoethyl)-γ-aminopropyltrimethoxysilane has been chemically grafted onto the nano-silica particles.

[0042] Preparation of o-hydroxybenzoyl chloride: Weigh ...

Embodiment 2

[0046] The specific technical scheme is basically the same as in Example 1, except that the nano-silica particles (A-200) used are 10 grams, and the N-(β-aminoethyl)-γ-aminopropyltriethoxysilane used is 10 grams, the preparation of o-hydroxybenzoyl chloride is enlarged by 4 times, and the tertiary amine catalyst adopts 0.2 milliliters of triethylamine, and the time for the normal temperature stirring reaction of the functionalized nano-silicon dioxide whose surface is grafted with ultraviolet-absorbing functional groups is 12 Hours, the prepared functionalized nano-silica grafted with UV-absorbing functional groups on the surface is grafted by N-(β-aminoethyl)-γ-aminopropyltriethoxysilane as a bridge to act as a UV The absorber group is o-hydroxybenzoyl, wherein the N-(β-aminoethyl)-γ-aminopropyltriethoxysilane accounts for the function of the surface grafted with ultraviolet absorbing functional groups 11.2% of the total weight of nano silicon dioxide, and the described o-hyd...

Embodiment 3

[0048] The specific technical scheme is basically the same as in Example 1, except that 10 grams of nano-silica particles (A-200) are used, 0.6 grams of gamma-aminopropyl triethoxysilane is used, and 0.35 grams of o-hydroxybenzoyl chloride is used. The reaction of salicylic acid with 8 milliliters of thionyl chloride is prepared, and the organic solvent of functionalized nano silicon dioxide grafted with ultraviolet absorbing functional groups on the surface adopts N, N-dimethylformamide, and the prepared The functionalized nano-silica grafted with ultraviolet absorbing functional groups on the surface is o-hydroxybenzoyl grafted as ultraviolet absorber groups through gamma-aminopropyltriethoxysilane as a bridge, wherein the γ-aminopropyltriethoxysilane accounts for 3.11% of the total weight of the functionalized nano-silica with ultraviolet absorbing functional groups grafted on the surface, and the 2.14% of the total weight of the o-hydroxybenzoyl .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com