Hydrogel for sewage treatment as well as preparation method thereof

A sewage treatment and hydrogel technology, applied in the direction of adsorption water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor selectivity, low efficiency, low adsorption capacity, etc., and achieve high performance The effect of stability, simple preparation process, and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

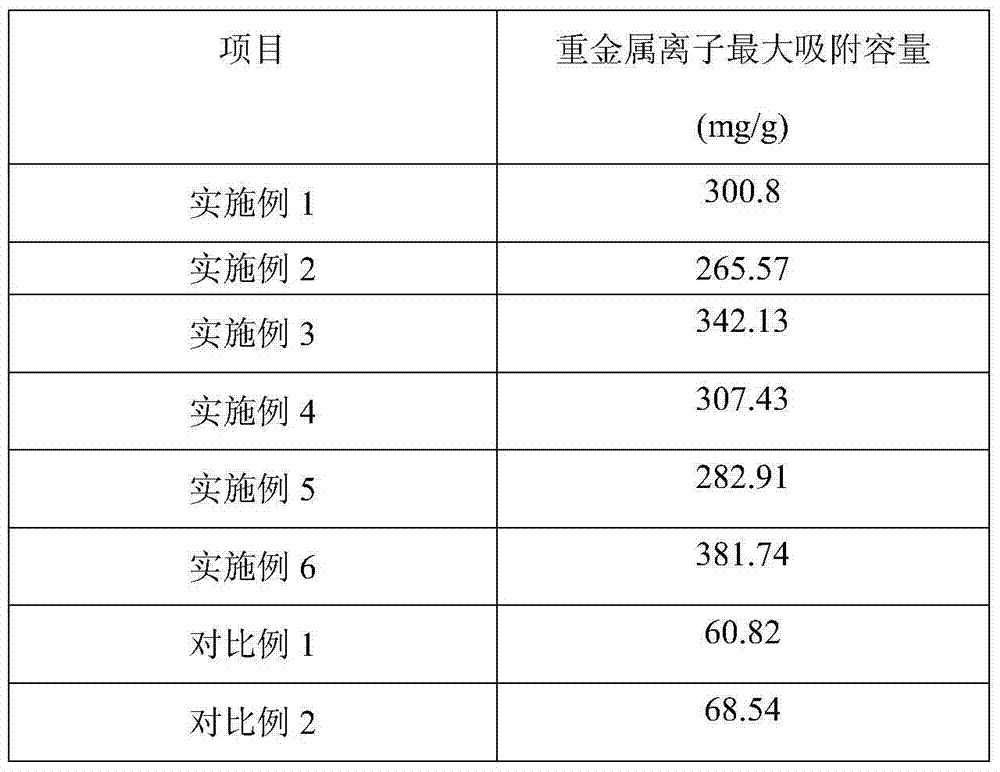

Embodiment 1

[0025] Weigh 5g of polyvinyl alcohol, 3g of sodium alginate, 5g of sodium carboxymethyl cellulose and 95mL of deionized water into a three-neck flask, heat in a boiling water bath, stir mechanically for 2 hours to make it completely mixed, and put the mixture at 80°C Heated in a water bath, then added 5g of chitosan, and mechanically stirred for 6h. Cool the above mixed solution to room temperature, add 50 mL of a graphene oxide aqueous solution with a concentration of 1 g / L to the mixed solution and sonicate for 0.5 h, then mechanically stir for 0.5 h to uniformly disperse the graphene oxide. Drop the above-prepared mixed solution into 3% calcium chloride-boric acid saturated solution with a syringe to prepare composite hydrogel beads with a particle size of 2 to 3 mm, soak for 24 hours, and finally rinse with deionized water for 5 times and soak in water .

[0026] Weigh the above-mentioned hydrogel pellets with a dry weight of 0.025g and place them in 100mL Erlenmeyer flas...

Embodiment 2

[0031] Weigh 5g of polyvinyl alcohol, 3g of sodium alginate and 95mL of deionized water into a three-neck flask, heat in a boiling water bath, stir mechanically for 2 hours to make it completely mixed, heat the mixture in a water bath at 80°C, and then add 10g Chitosan, and mechanically stirred for 6h. Cool the above mixed solution to room temperature, add 50 mL of a graphene oxide aqueous solution with a concentration of 1 g / L to the mixed solution and sonicate for 0.5 h, then mechanically stir for 0.5 h to uniformly disperse the graphene oxide. Drop the above-prepared mixed solution into 3% calcium chloride-boric acid saturated solution with a syringe to prepare composite hydrogel beads with a particle size of 2 to 3 mm, soak for 24 hours, and finally rinse with deionized water for 5 times and soak in water .

[0032] Weigh the above-mentioned hydrogel pellets with a dry weight of 0.025g and place them in 100mL Erlenmeyer flasks, and then add 25mL of them in sequence with c...

Embodiment 3

[0034] Weigh 5g of polyvinyl alcohol, 3g of sodium alginate, 0.1g of sodium sulfite, 5g of sodium carboxymethyl cellulose and 95mL of deionized water into a three-necked flask, heat in a boiling water bath, stir mechanically for 2 hours to make it completely mixed, and mix The solution was heated in a water bath at 80°C, then 5g of chitosan was added, and mechanically stirred for 6h. Cool the above mixed solution to room temperature, add 50 mL of a graphene oxide aqueous solution with a concentration of 1 g / L to the mixed solution and sonicate for 0.5 h, then mechanically stir for 0.5 h to uniformly disperse the graphene oxide. Drop the above-prepared mixed solution into 3% calcium chloride-boric acid saturated solution with a syringe to prepare composite hydrogel beads with a particle size of 2 to 3 mm, soak for 24 hours, and finally rinse with deionized water for 5 times and soak in water .

[0035] Weigh the above-mentioned hydrogel pellets with a dry weight of 0.025g and pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com