Anode material for lithium ion battery and preparation method of anode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as environmental pollution, increase in production costs, low electronic conductivity and ion conductivity, and achieve high initial discharge specific capacity , good rate performance, and the effect of increasing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

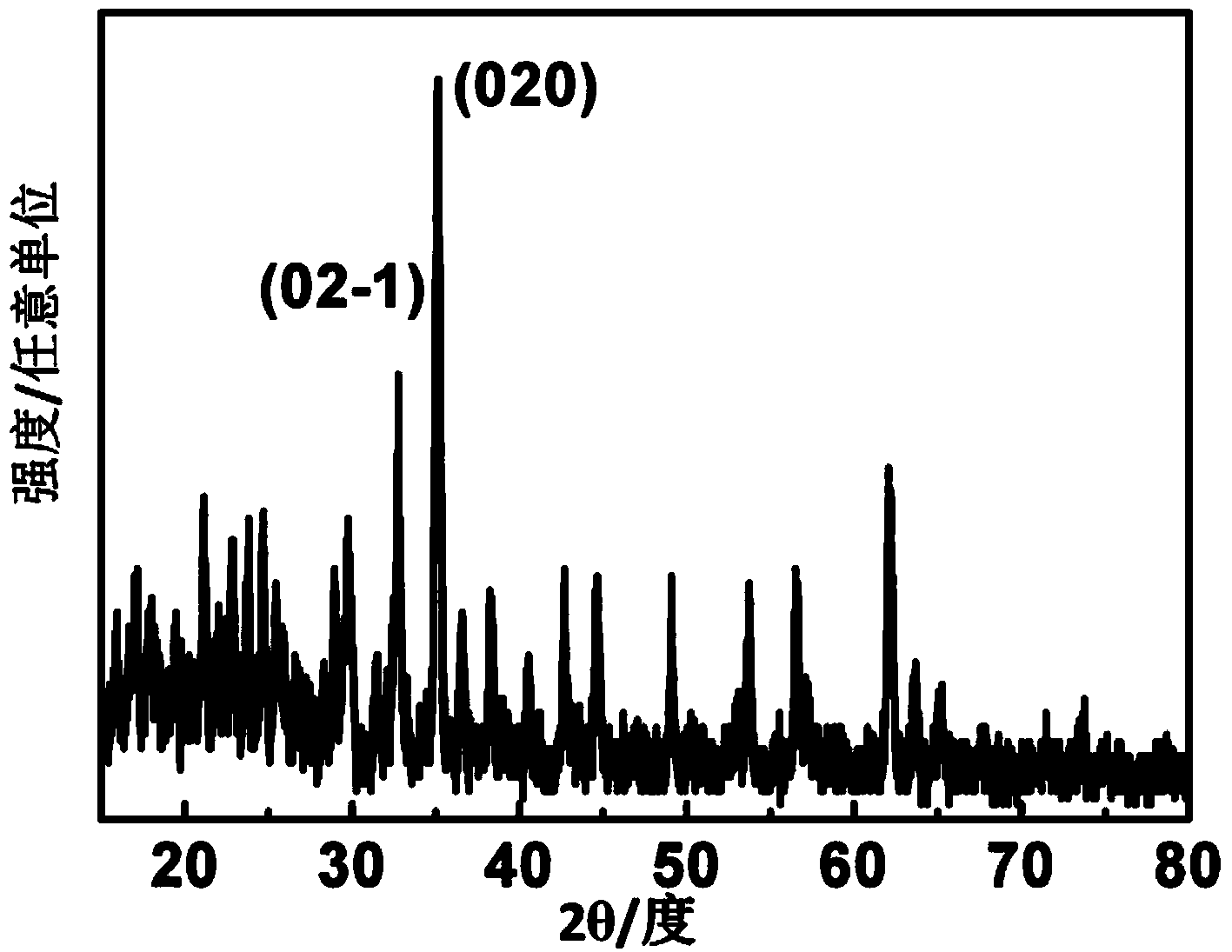

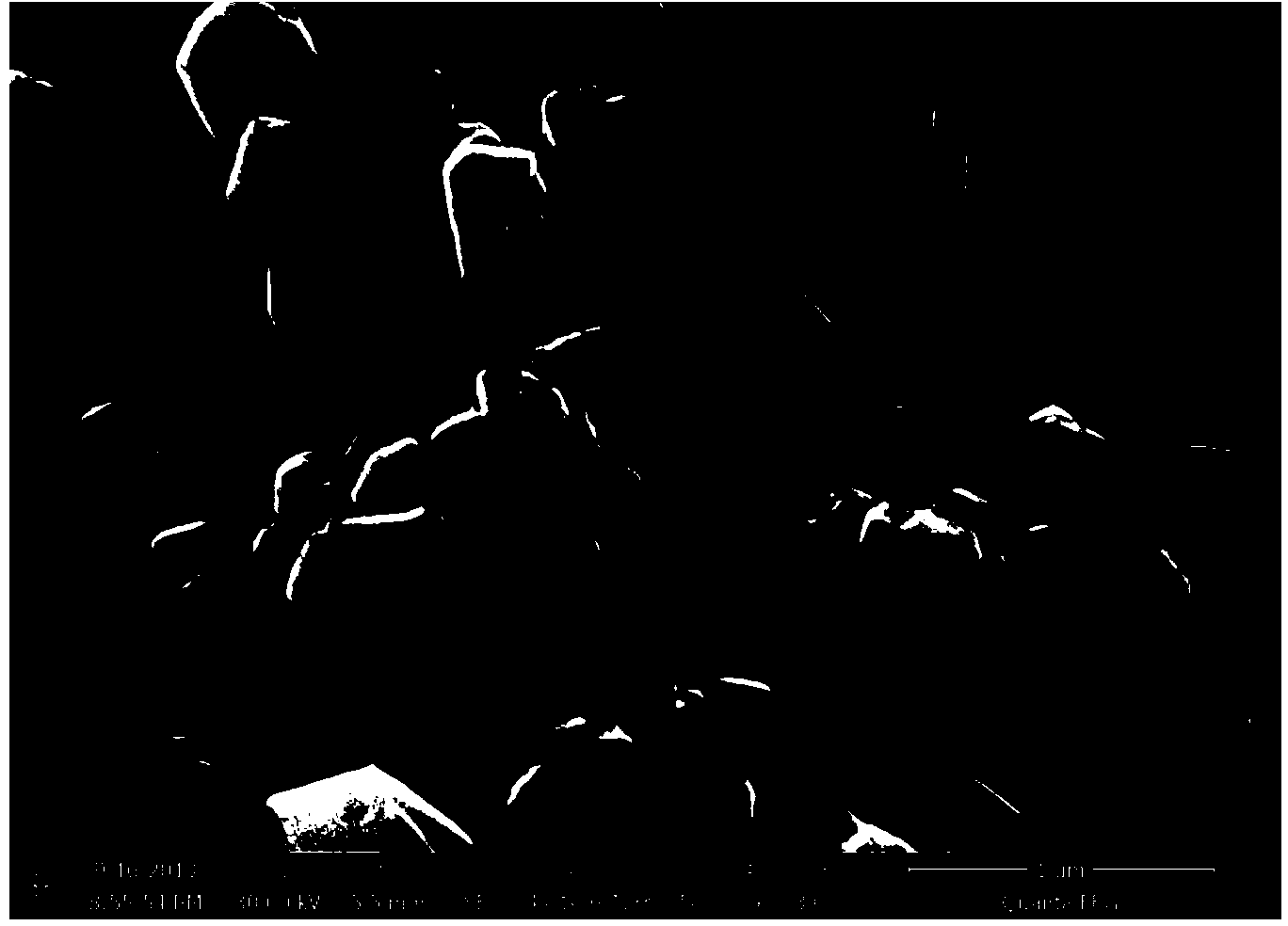

[0018] Embodiment 1, the precursor FeSO 4 7H 2 O (99.9%) and LiF (99.9%) were put into a zirconia ball mill jar at a molar ratio of 1:1.2 together with absolute ethanol (amount to submerge the ball milling beads and abrasives) for high-energy ball milling. After 24 h of ball milling, the mixture was placed Dry in a vacuum oven at 60°C for 24 h. After the alcohol is completely volatilized, grind the mixture into a fine powder by hand in an agate mortar, then compact it into a disc, and put it in a ceramic boat at 380°C under the protection of inert gas nitrogen. Lithium fluoroferric sulfate (LiFeSO 4 F) Cathode material, such as figure 1 is the X-ray diffraction pattern of the prepared cathode material, figure 2 is the SEM image of the as-prepared cathode material.

Embodiment 2

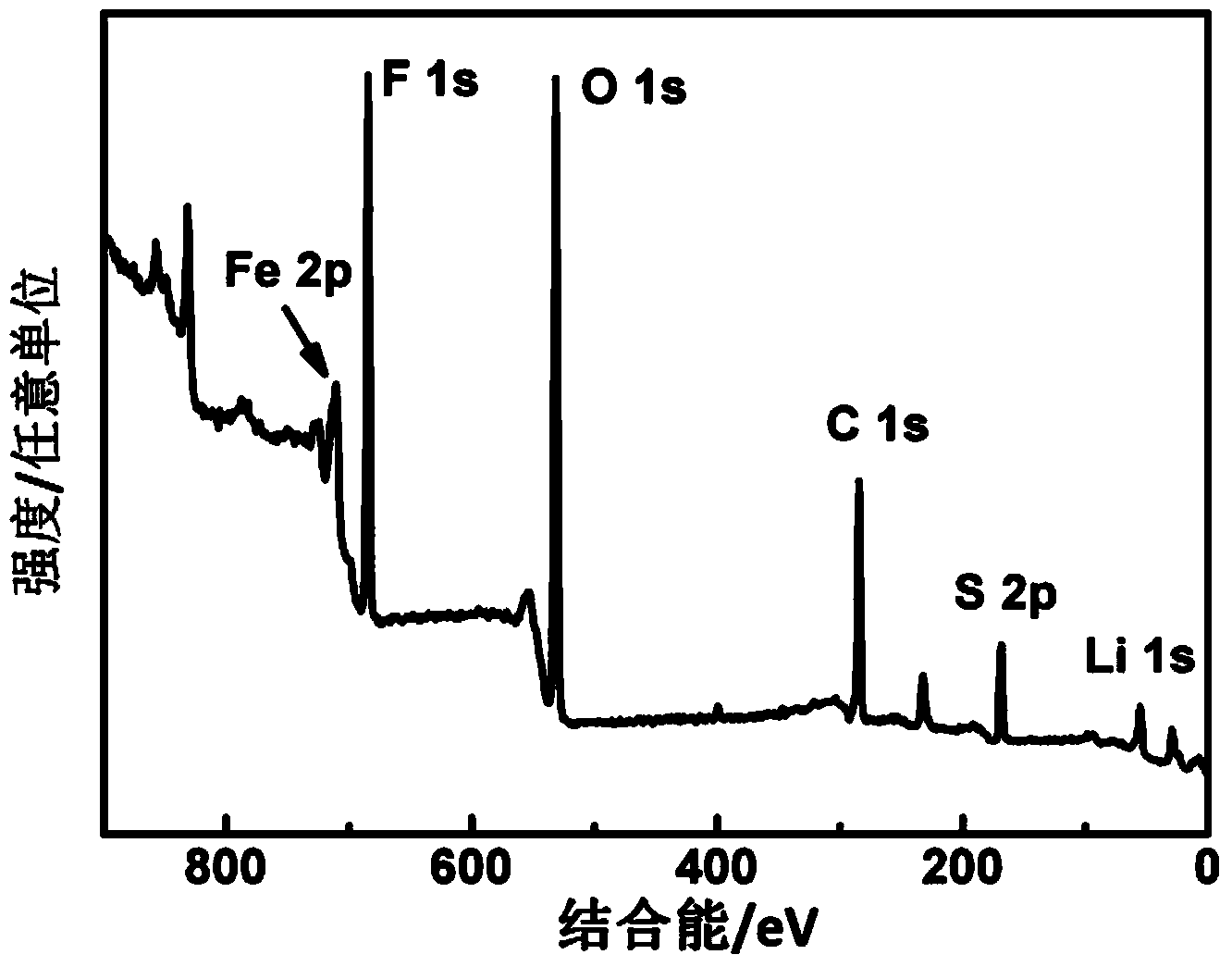

[0019] Embodiment 2, the precursor FeSO 4 7H 2 O (99.9%) and LiF (99.9%) were put into a zirconia ball mill jar at a molar ratio of 1:1 together with absolute ethanol (amount to submerge the ball milling beads and abrasives) for high-energy ball milling. After 24 h of ball milling, the mixture was placed Dry in a vacuum drying oven at 60°C for 24 h. After the alcohol is completely volatilized, the mixture is manually ground into a fine powder in an agate mortar, then compacted into a disc, and placed in a ceramic boat at 380°C under the protection of an inert gas argon. Lithium fluoroiron sulfate (LiFeSO 4 F) Cathode material, such as image 3 is the X-ray photoelectron energy spectrum of the prepared lithium iron sulfate fluoride.

Embodiment 3

[0020] Embodiment 3, the precursor FeSO 4 7H 2 O (99.9%) and LiF (99.9%) were put into a zirconia ball mill pot for high-energy ball milling at a molar ratio of 1:1.2 together with absolute ethanol (amount to submerge ball milling beads and abrasives). After 24 hours of ball milling, the The mixture was dried in a vacuum drying oven at 60°C for 24 hours. After the alcohol was completely volatilized, the mixture was manually ground into a fine powder in an agate mortar, then compacted into discs, and placed in a ceramic boat at 380°C under the protection of inert gas nitrogen. Lithium fluoroiron sulfate (LiFeSO 4 F) Cathode material; The LiFeSO that will make 4 Grind the positive electrode active material until the particle size is less than 7 μm, sieve, weigh the active material, acetylene black, and binder PVDF according to the ratio of mass 8:1:1, add NMP, stir at 80°C for 4 h, and prepare Electrode paste, coated on clean aluminum foil and cut into 0.8×0.8 cm 2 The elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com