Bacteria cellulose producing strain and method for fermenting bacteria cellulose by utilizing same

A bacterial cellulose and bacteria-producing technology, which is applied in the field of bacterial cellulose producing bacteria and bacterial cellulose fermentation, can solve the problems of increased production efficiency, long production cycle, long time, etc., and achieve improved moisturizing, increased strength, and improved sound quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

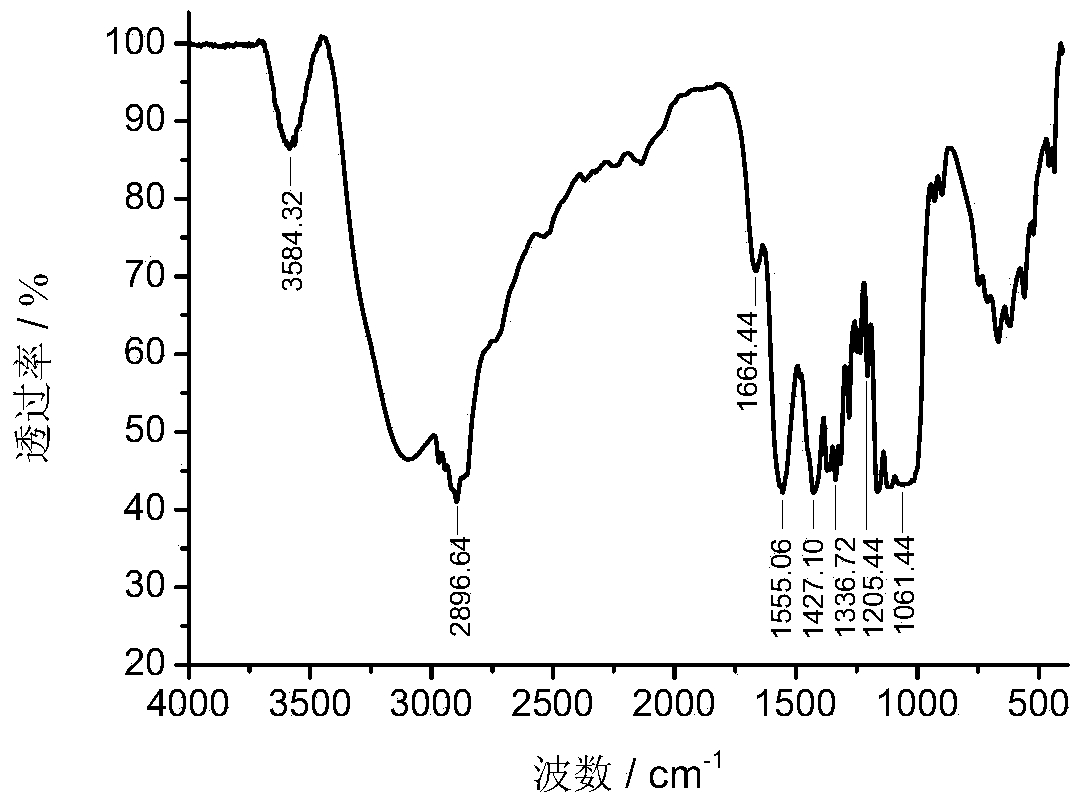

Image

Examples

Embodiment 1

[0050] Example 1 Screening, domestication and isolation of bacteria cellulose producing bacterium Gluconacetobacter xylinus (Gluconacetobacter xylinus) BC13

[0051] The bacterial cellulose producing bacterium Gluconacetobacter xylinus (Gluconacetobacter xylinus) BC13 described in the present invention is isolated and screened from coconut water (sampled in Hainan Province) that is fermented and produced naturally. The specific screening, domestication, isolation and product identification methods are as follows:

[0052] (1) Plate separation

[0053] Solid medium: glucose 20g / L, yeast extract 10g / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O0.2g / L, agar 20g / L, fresh coconut water 50% (v / v), adjust pH5.5, 121 ℃ of sterilization 20min. Prepare a plate according to the solid medium formula and set aside. Under aseptic conditions, remove the bacterial film on the surface from the naturally fermented coconut water, cut 2 g into a sterile test tube, add 10 mL of sterile water, place it o...

Embodiment 2

[0071] The bacterial cellulose strain is Gluconacetobacter xylinus (Gluconacetobacter xylinus) BC13, which was preserved in China Center for Type Culture Collection (CCTCC) on April 10, 2014, address: Wuhan University, Wuhan, China, and the preservation number is CCTCC NO: M2014124;

[0072] (1) Expanded cultivation of seeds

[0073] Seed expansion medium preparation: glucose 2g, yeast extract 0.8g, MgSO 4 ·7H 2 0.02g, 50mL of coconut water (fresh coconut, broken shell to get water), 50mL of purified water, adjust pH5.5, put into a 500mL triangular bottle, wrap the mouth of the bottle with 8 layers of gauze, sterilize at 121°C for 20min, cool to 30°C, Insert 1 ring of slant strains (inoculated with a conventional inoculation loop), place in a shaking incubator at a constant temperature of 30°C and shake at 150r / min for 16 hours to obtain a seed solution;

[0074] (2) deep dynamic fermentation

[0075] Fermentation medium preparation: glucose 75g, yeast extract 12g, NH 4 C...

Embodiment 3

[0086] The bacterial cellulose strain is Gluconacetobacter xylinus (Gluconacetobacter xylinus) BC13, which was preserved in China Center for Type Culture Collection (CCTCC) on April 10, 2014, address: Wuhan University, Wuhan, China, and the preservation number is CCTCC NO: M2014124;

[0087] (1) Expanded cultivation of seeds

[0088] Seed expansion medium preparation: glucose 4g, yeast extract 1.6g, MgSO 4 ·7H 2 0.04g, 100mL of coconut water (fresh coconut, broken shell to get water), 100mL of purified water, adjust pH5.5, put into a 500mL triangular bottle, wrap the mouth of the bottle with 8 layers of gauze, sterilize at 121°C for 20min, cool to 30°C, Insert 1 ring of slant strains (inoculated with a conventional inoculation loop), place in a shaking incubator at a constant temperature of 30°C and shake at 150r / min for 16 hours to obtain a seed solution;

[0089] (2) deep dynamic fermentation

[0090] Fermentation medium preparation: glucose 100g, yeast extract 14.4g, NH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com