Combined method for measuring content of impurity elements and matrix element niobium in niobium-iron alloy

An impurity element and ferroniobium alloy technology, applied in material excitation analysis, thermal excitation analysis, etc., can solve the problems of long inspection process, complicated operation, secondary pollution, etc., and achieve good accuracy and reliability, convenient operation and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] In the example of the present invention, the ICP-OES is an iCAP6300 Inductively Coupled Plasma Atomic Emission Spectrometer from Thermo Fisher Corporation of the United States.

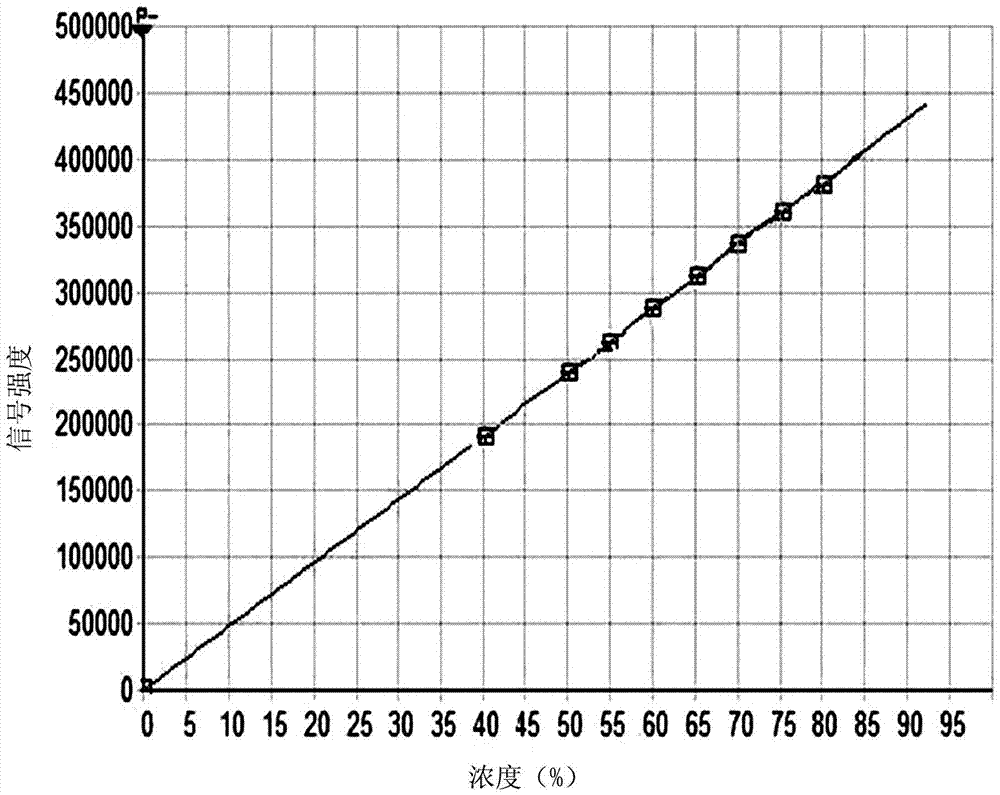

[0045] 1. Digestion and preparation of ferroniobium test samples and standard samples

[0046] Weigh 0.1g of ferroniobium sample or standard sample into a polytetrafluoroethylene beaker, rinse the cup wall and disperse the sample without adding water, directly add 2mL hydrofluoric acid drop by drop to rinse the cup wall and ensure that the sample is completely soaked in hydrofluoric acid, at room temperature React under ambient conditions until the solution has no bubbles, add 3mL of concentrated nitric acid, immediately add 2mL of hydrogen peroxide when a large amount of nitrogen oxide brown smoke such as nitrogen dioxide is produced in the reaction, continue to react at room temperature until the sample is completely digested, dilute with water to volume In a 100mL plastic volumetric flask, m...

example 2

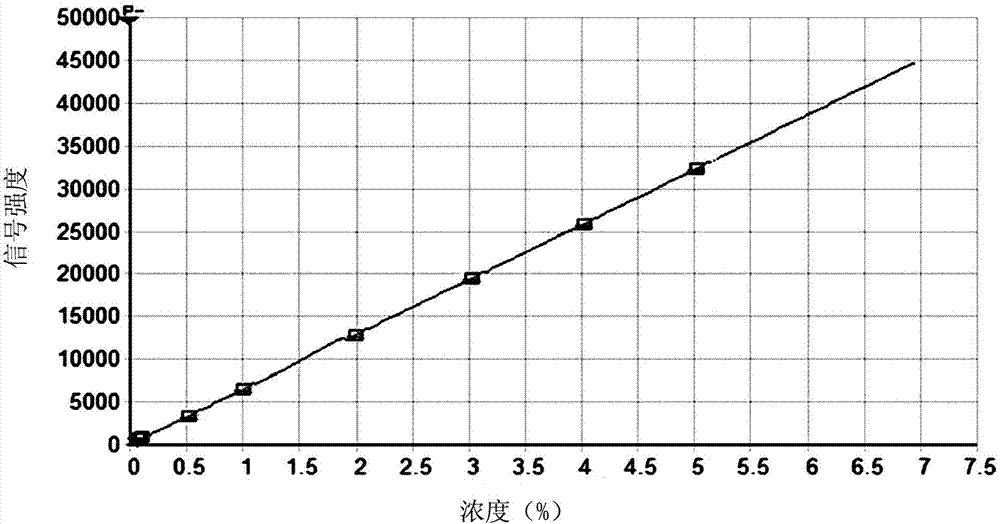

[0054] Except for the following differences, all the others adopt the same method as Example 1 to measure the ferroniobium sample of Example 2: 0.3g of ferroniobium sample is weighed, 3mL of hydrofluoric acid consumption, 8mL of concentrated nitric acid consumption, 3mL of hydrogen peroxide consumption . The working parameters of the ICP spectrometer are RF power 1700W, peristaltic pump speed 80r / min, and atomizing gas pressure 0.40MPa. When measuring niobium for the second time, dilute the sample solution to be tested and 8 mixed standard solutions at a ratio of 20 times, that is, take 5.0mL of the sample solution to be tested and the mixed standard solution in a 100mL plastic volumetric flask and dilute with water to determine Allow. The carbon content in sample 2 is about 3.5%.

example 3

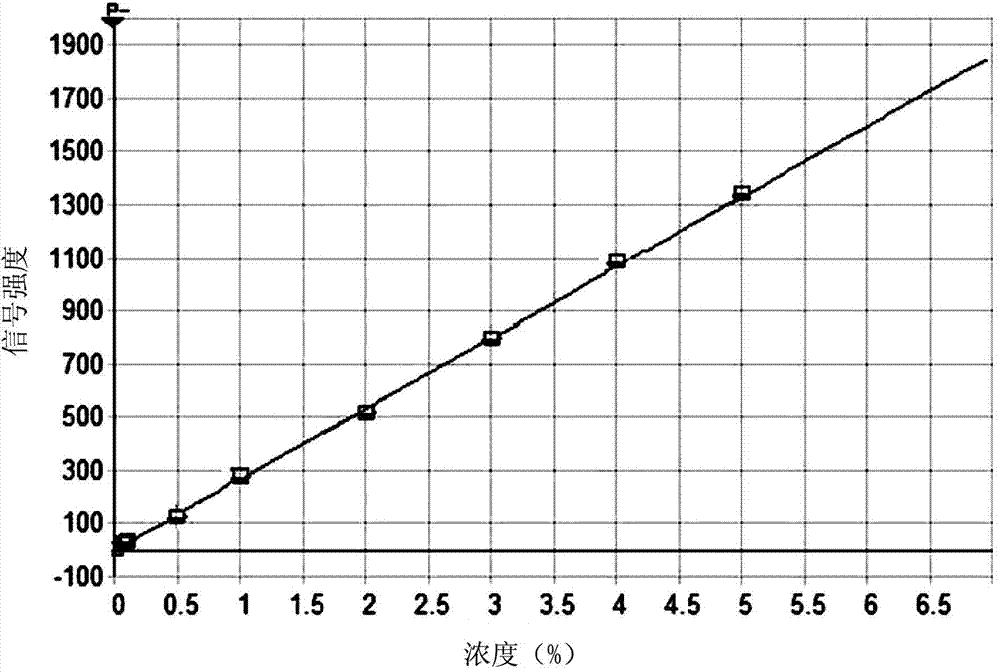

[0056] Except for the following differences, all the others adopt the same method as Example 1 to measure the ferroniobium sample of Example 3: the ferroniobium sample is weighed 0.15g, the amount of hydrofluoric acid is 2.5mL, the amount of concentrated nitric acid is 6mL, and the amount of hydrogen peroxide is 2.5mL. The working parameters of the ICP spectrometer are RF power 1600W, peristaltic pump speed 75r / min, atomizing gas pressure 0.38MPa. For the second determination of niobium, divide 8.0mL of the sample solution to be tested and the mixed standard solution into a 100mL plastic volumetric flask and dilute with water to volume. The carbon content in sample 3 is 0.07%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com