Polymer for purifying air and preparation method and use thereof

A technology for purifying air and polymers, which is applied in the field of air purification, and can solve problems such as large influence of light conditions and insufficient speed of decomposing harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

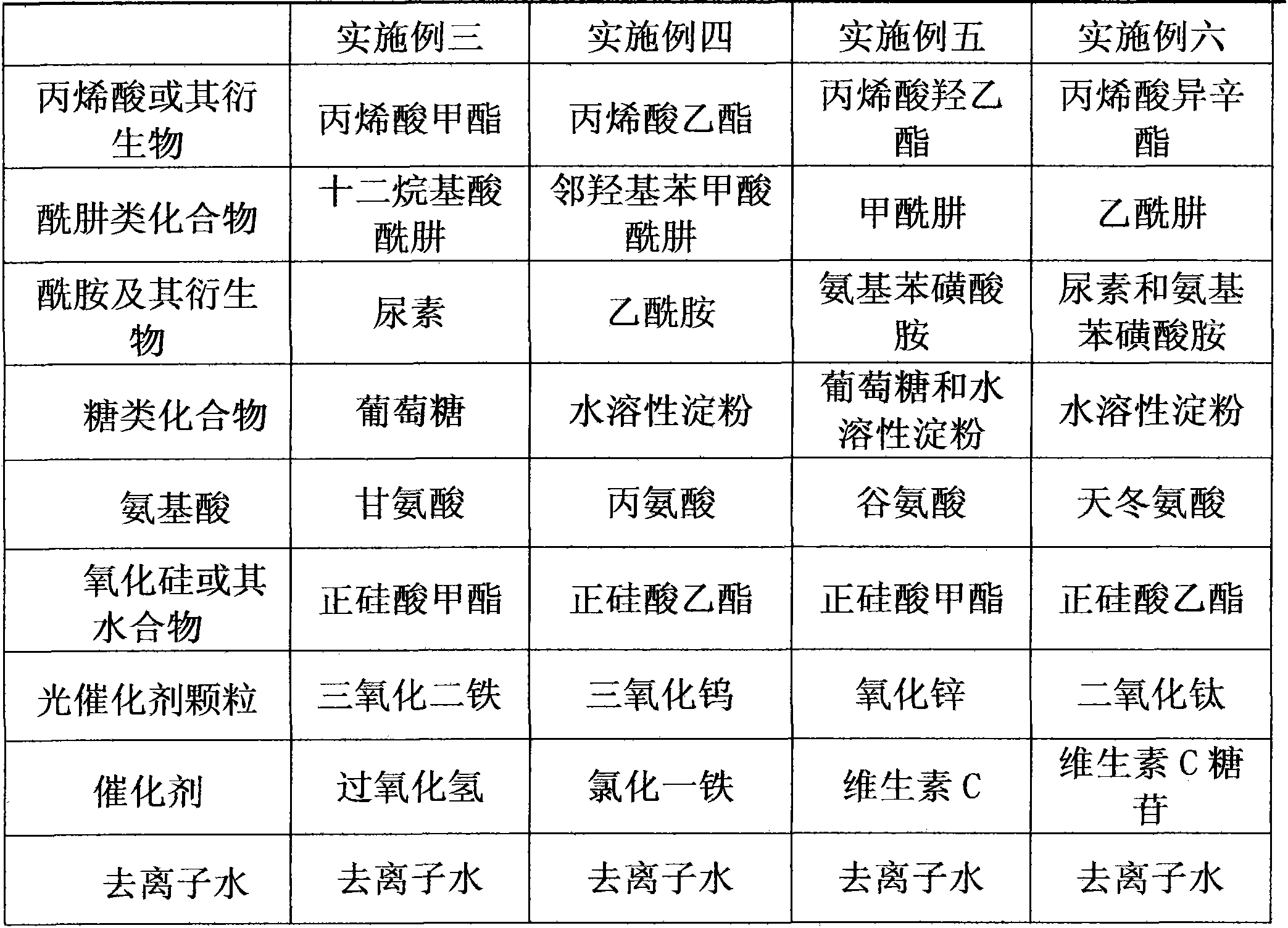

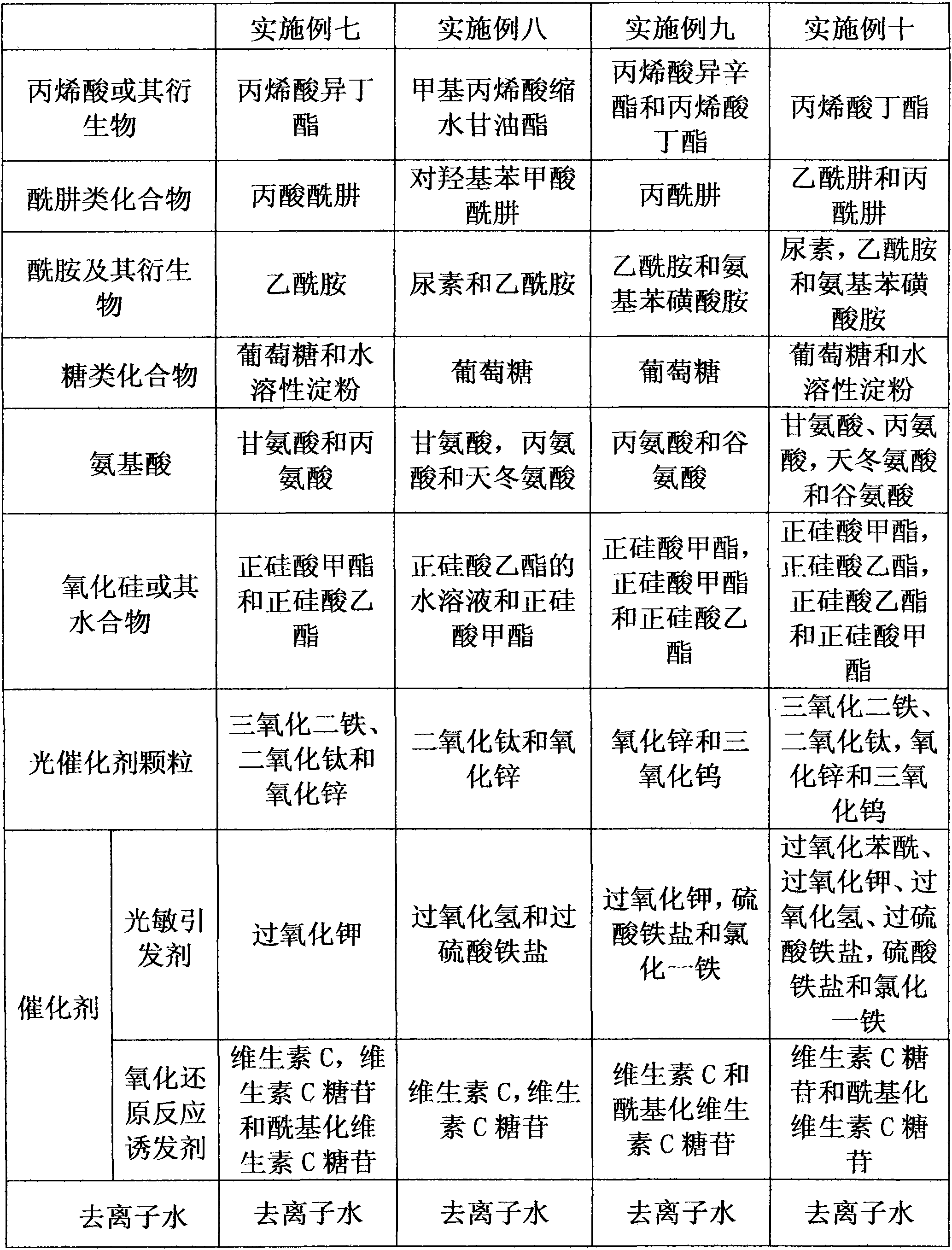

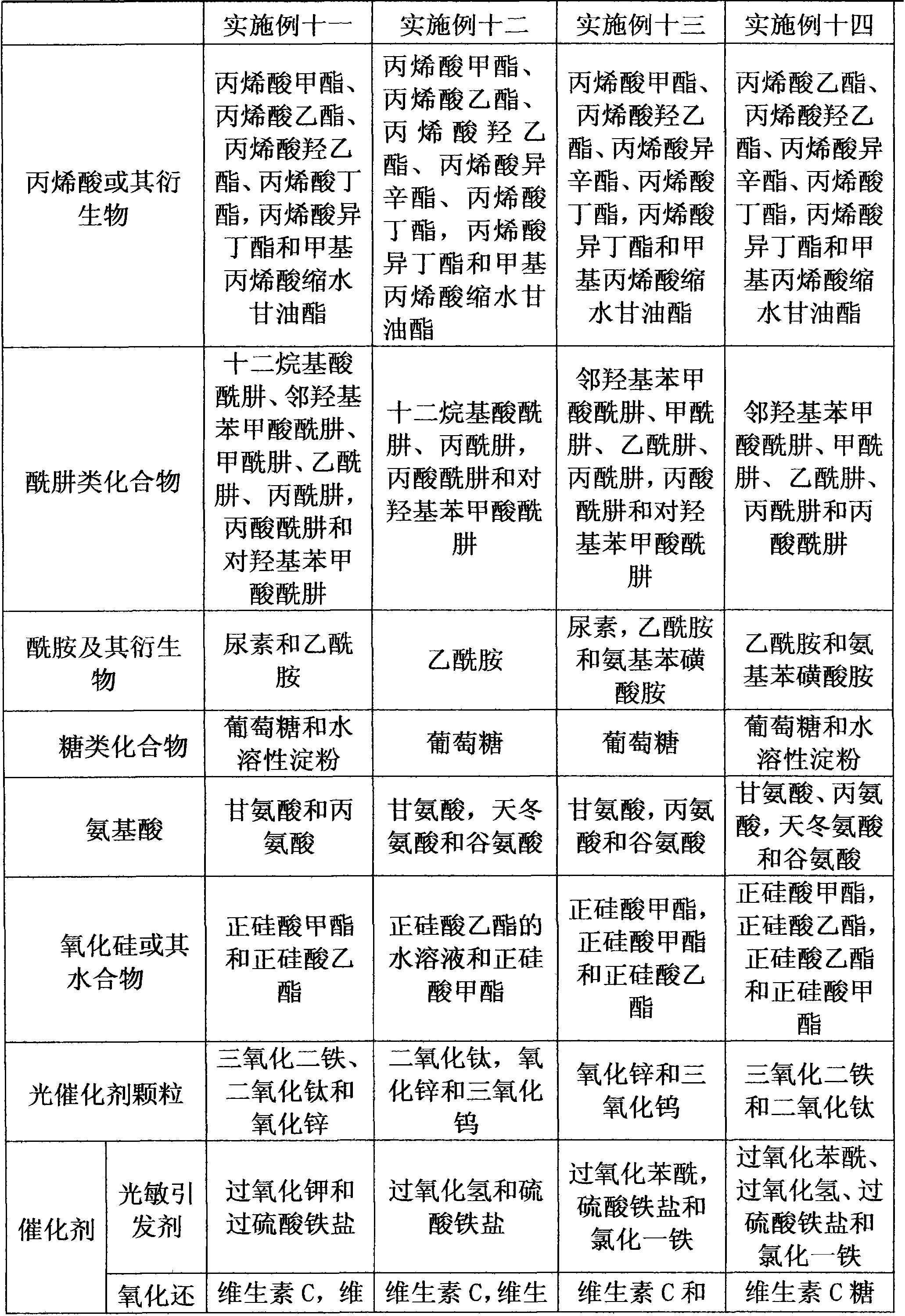

Examples

Embodiment 1

[0043] A polymer for air purification, which is prepared from the following raw materials: acrylic acid or its derivatives, hydrazide compounds, amides and their derivatives, sugar compounds, amino acids, silicon oxide or its hydrates, photocatalysts particles, catalyst and deionized water; acrylic acid or its derivatives is isooctyl acrylate; the hydrazide compound is propionic acid hydrazide and o-hydroxybenzoic acid hydrazide; amide and its derivatives are p-aminobenzenesulfonate The carbohydrate compound is glucose; the amino acid is aspartic acid; silicon oxide or its hydrate is an aqueous solution of methyl orthosilicate; the photocatalyst particle is ferric oxide; the catalyst is a photoinitiator, and the photoinitiator is Benzoyl peroxide;

[0044] The preparation method comprises the steps of:

[0045] 1. Put deionized water into the beaker;

[0046] 2. Add acrylic acid or its derivatives, hydrazide compounds, amides and their derivatives, sugar compounds, amino aci...

Embodiment 2

[0052] A polymer for air purification, which is prepared from the following raw materials: acrylic acid or its derivatives, hydrazide compounds, amides and their derivatives, sugar compounds, amino acids, silicon oxide or its hydrates, photocatalysts Granules, catalysts and deionized water; acrylic acid or its derivatives are hydroxyethyl acrylate; the hydrazide compound is lauryl acid hydrazide; amide and its derivatives are urea; the sugar compound is water-soluble starch; The amino acid is glycine and alanine; the silicon oxide or its hydrate is methyl orthosilicate and ethyl orthosilicate; the photocatalyst particles are zinc oxide; the catalyst includes a photoinitiator and adding a redox reaction inducer; The agent is ferric persulfate and ferric sulfate; the redox reaction inducer is acylated vitamin C glycoside;

[0053] The preparation method comprises the steps of:

[0054] 1. Put deionized water into the beaker;

[0055] 2. Add acrylic acid or its derivatives, hyd...

Embodiment 3

[0065] In embodiment three, the ultraviolet lamp in the step three irradiates the mixed solution in the step two, and the irradiation intensity is 2mW / cm 2 ; The mixed solution where the polymerization reaction occurs in the step five does not appear to be stratified or precipitated, and the rotational viscosity is 2000mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

| Rotational viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com