A kind of preparation method of lithium nitrogen co-doped diamond film

A diamond film and co-doping technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems that there is no preparation method of lithium-nitrogen co-doped diamond film, and achieve high electron migration ability , shallow donor energy level, simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

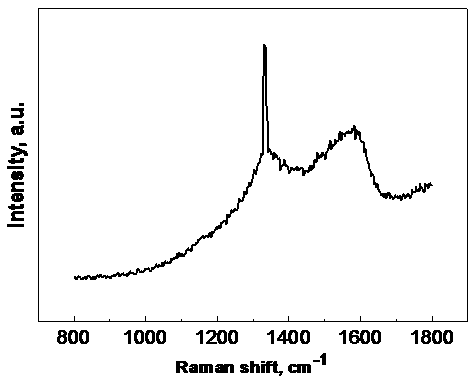

[0015] The invention provides a method for preparing a lithium-nitrogen co-doped diamond film. A layer of suspension containing a Li source is coated on the surface of a substrate on which a diamond film is pre-deposited, and it is put into a hot wire chemical vapor deposition system after being dried. In the reaction chamber, the powder containing the Li source is melted by heating and the Li diffuses into the diamond; the hot wire chemical vapor deposition method is further used to deposit the lithium-nitrogen co-doped diamond film in a nitrogen-containing atmosphere, which specifically includes the following steps:

[0016] Step 1. Dissolving the lithium source solid powder in an organic solvent, and forming a stable suspension by ultrasonic treatment. The specific operation is: dissolving the solid lithium source powder in an organic solvent, and then ultrasonically treating it to prepare a suspension with good stability. The lithium source solid powder is lithium nitride,...

Embodiment 1

[0023] Coat a layer of suspension containing Li source on the substrate surface deposited with nitrogen-doped diamond film, put it into the reaction chamber of the hot wire chemical vapor deposition system after drying, and melt the powder containing Li source by heating And make Li diffuse into the diamond; further adopt the hot wire chemical vapor deposition method to deposit lithium nitrogen co-doped diamond film in nitrogen-containing atmosphere, specifically comprising the following steps:

[0024] Step 1. Dissolving the lithium source solid powder in an organic solvent, and forming a stable suspension by ultrasonic treatment. The specific operation is: dissolving lithium nitride solid powder in chloroform organic solvent, and then ultrasonically treating it to prepare a suspension with good stability.

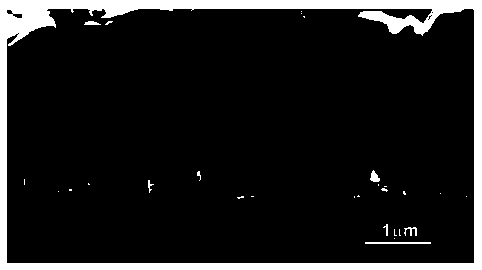

[0025] Step 2. Coat the prepared suspension on the substrate deposited with a 0.5 μm nitrogen-doped diamond film. After natural drying, place it on the sample stage of th...

Embodiment 2

[0031] Coat a layer of suspension containing Li source on the surface of the substrate deposited with intrinsic diamond film, put it into the reaction chamber of the hot wire chemical vapor deposition system after drying, and melt the powder containing Li source by heating Diffusion of Li into the diamond; further adopting a hot wire chemical vapor deposition method to deposit a lithium-nitrogen co-doped diamond film in a nitrogen-containing atmosphere, specifically comprising the following steps:

[0032] Step 1. Dissolving the lithium source solid powder in an organic solvent, and forming a stable suspension by ultrasonic treatment. The specific operation is: dissolving lithium carbide solid powder in toluene organic solvent, and then ultrasonically treating it to prepare a suspension with good stability.

[0033] Step 2. Coat the prepared suspension on the substrate deposited with a 5 μm intrinsic diamond film. After natural drying, place it on the sample stage of the vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com