Anti-crease finishing agent for acrylamido cotton fabric, and preparation method and application thereof

An anti-wrinkle finishing agent and acrylamide-based technology are applied in the field of acrylamide-based anti-wrinkle finishing agents for cotton fabrics and their preparation, which can solve the problems of only being suitable for pad dyeing and printing, difficult cross-linking effect, poor directness of fibers, and the like. Effects of temperature reduction, improved water solubility, high anti-wrinkle properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

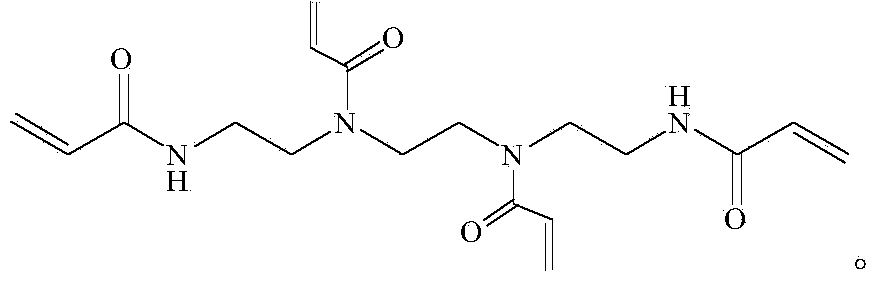

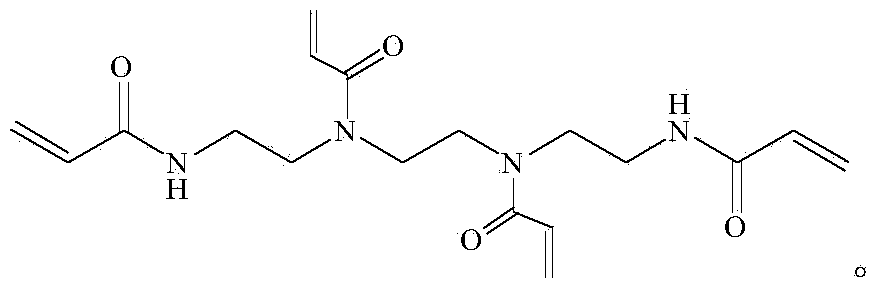

[0026] In a 1L three-necked flask, add 40g of ethylenediamine, 90g of sodium hydroxide, 200g of water, and 600mL of acetonitrile, and mechanically stir in an ice bath. After the temperature dropped below 5°C, 132.6 g of acryloyl chloride was added dropwise within 1 hour. After the dropwise addition, the ice bath was removed, and the solution was reacted at room temperature for 5 h. Then, acetonitrile was removed by distillation under reduced pressure, and the product was extracted from the aqueous solution with 400 mL of chloroform, and dried by adding magnesium sulfate overnight. After filtering magnesium sulfate, chloroform was distilled off again under reduced pressure to obtain the final product.

[0027] The structural formula is n=2.

[0028] The above product is formulated into 100g of anti-wrinkle finishing solution, the finishing agent is 7% of the quality of the finishing solution, sodium hydroxide is 5% of the quality of the finishing solution, Pingping plus O i...

Embodiment 2

[0030] In a 1L three-necked flask, add 222g of 1,8-diamino-3,6-dioxahexane, 90g of sodium hydroxide, 200g of water, and 500mL of isopropanol, and mechanically stir in an ice bath. After the temperature dropped below 5°C, 132.6 g of acryloyl chloride was added dropwise within 1 hour. After the dropwise addition, the ice bath was removed, and the solution was reacted at room temperature for 5 h. Then, the isopropanol was removed by distillation under reduced pressure, and the product was extracted from the aqueous solution with 400 mL of ethyl acetate, and dried by adding magnesium sulfate overnight. After filtering the magnesium sulfate, the ethyl acetate was distilled off again under reduced pressure to obtain the final product.

[0031] The structural formula is

[0032] Above-mentioned product is formulated into 100g of anti-wrinkle finishing liquid, and finishing agent is 9% of the quality of finishing liquid, and sodium bicarbonate is 10% of the quality of finishing li...

Embodiment 3

[0034]In a 1L three-neck flask, add 125g of 1,4-diaminobenzenesulfonic acid, 90g of sodium hydroxide, 200g of water, and 800mL of acetonitrile, and mechanically stir in an ice bath. After the temperature dropped below 5°C, 132.6 g of acryloyl chloride was added dropwise within 1 hour. After the dropwise addition, the ice bath was removed, and the solution was reacted at room temperature for 5 h. Then, acetonitrile was removed by distillation under reduced pressure, and the product was extracted from the aqueous solution with 400 mL of ethyl acetate, and dried by adding magnesium sulfate overnight. After filtering the magnesium sulfate, the ethyl acetate was distilled off again under reduced pressure to obtain the final product.

[0035] The structural formula is

[0036] Above-mentioned product is formulated into anti-wrinkle finishing solution 100g, and finishing agent is 10% of the quality of finishing solution, and sodium carbonate is 10% of the quality of finishing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com