Preparation method of microcarrier-cell compound with induction activity and application of compound

A technology for inducing activity and complexes, applied in the field of biomedical materials, it can solve the problem of limited bone defect repair effect, low specific surface area, low effective adhesion area cell culture-related parameters, and lack of combined use of osteoblasts and fibroblasts. It can improve the content of matrix components and the degree of calcification, improve the utilization efficiency of seed cells, and improve the effect of bone defect repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

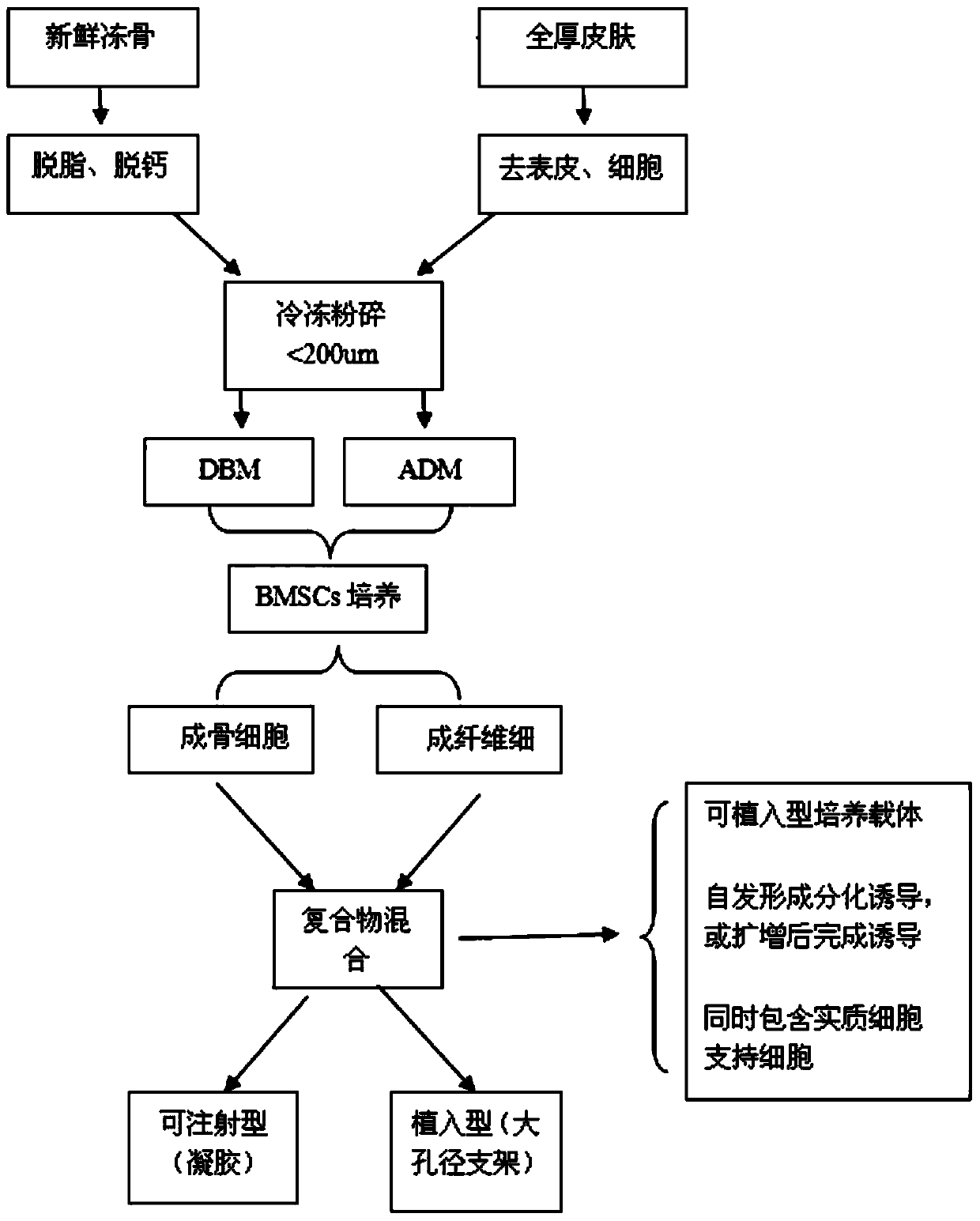

[0025] see figure 1 , the present invention has the preparation method of inducing active microcarrier-cell complex comprising the following steps:

[0026] 1) Preparation of decalcified bone matrix microparticles: Store frozen bovine cortical bone at -80°C for 24-36 hours, then freeze and pulverize; screen out particles with a particle size of less than 200um; degrease and decalcify the particles to obtain decalcified Calcium bone matrix microparticles; the specific conditions for degreasing and decalcifying treatment are that the particles are put into the degreasing mixed solution and stirred for 2-6 hours to obtain the degreased particles; wherein the mixed solution is methanol and chloroform by volume ratio (1- 3): obtained by mixing 1, and adding 1g of granules to every 3mL of the mixed solution; adding the degreased granules to 0.5mol / L hydrochloric acid solution, stirring for 48-72h, to obtain decalcified bone matrix microparticles, wherein, Add 1 g of defatted partic...

Embodiment 1

[0033]1) Preparation of decalcified bone matrix microparticles: Store frozen bovine cortical bone at -80°C for 24 hours, then freeze and pulverize; screen out particles with a particle size of less than 200um; degrease and decalcify the particles to obtain decalcified bone Substrate microparticles; the specific conditions for degreasing and decalcifying treatment are as follows: put the particles into the degreasing mixture and stir for 6 hours to obtain degreased particles; wherein the mixture is obtained by mixing methanol and chloroform at a volume ratio of 1:1, And every 3mL of the mixed solution was added with 1g of particles; the degreased particles were added to 0.5mol / L hydrochloric acid solution, and stirred for 60 hours to obtain decalcified bone matrix microparticles. Add 1 g of defatted granules to hydrochloric acid.

[0034] 2) Preparation of acellular dermal matrix microparticles: take the full-thickness skin, first carry out sterilization treatment, soak in 1mol...

Embodiment 2

[0039] 1) Preparation of decalcified bone matrix microparticles: Store frozen bovine cortical bone at -80°C for 36 hours, then freeze and pulverize; screen out particles with a particle size of less than 200um; degrease and decalcify the particles to obtain decalcified bone Substrate microparticles; the specific conditions for degreasing and decalcifying treatment are as follows: put the particles into the degreasing mixture and stir for 2 hours to obtain degreased particles; wherein the mixture is obtained by mixing methanol and chloroform at a volume ratio of 2:1, And every 3mL of the mixed solution was added with 1g of granules; the degreased granules were added to 0.5mol / L hydrochloric acid solution, stirred for 72h to obtain decalcified bone matrix microparticles. Add 1 g of defatted granules to hydrochloric acid.

[0040] 2) Preparation of acellular dermal matrix microparticles: take the full-thickness skin, first sterilize it, soak it in 1mol / L NaCl solution for 12 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com