Preparation method of heavy metal ion adsorbent based on modified bacterial cellulose

A technology of bacterial cellulose and heavy metal ions, which is applied in microorganism-based methods, biochemical equipment and methods, chemical instruments and methods, etc., can solve the problems of weak adsorption capacity of plant cellulose and achieve good biocompatibility. , The process is simple, the adsorption effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

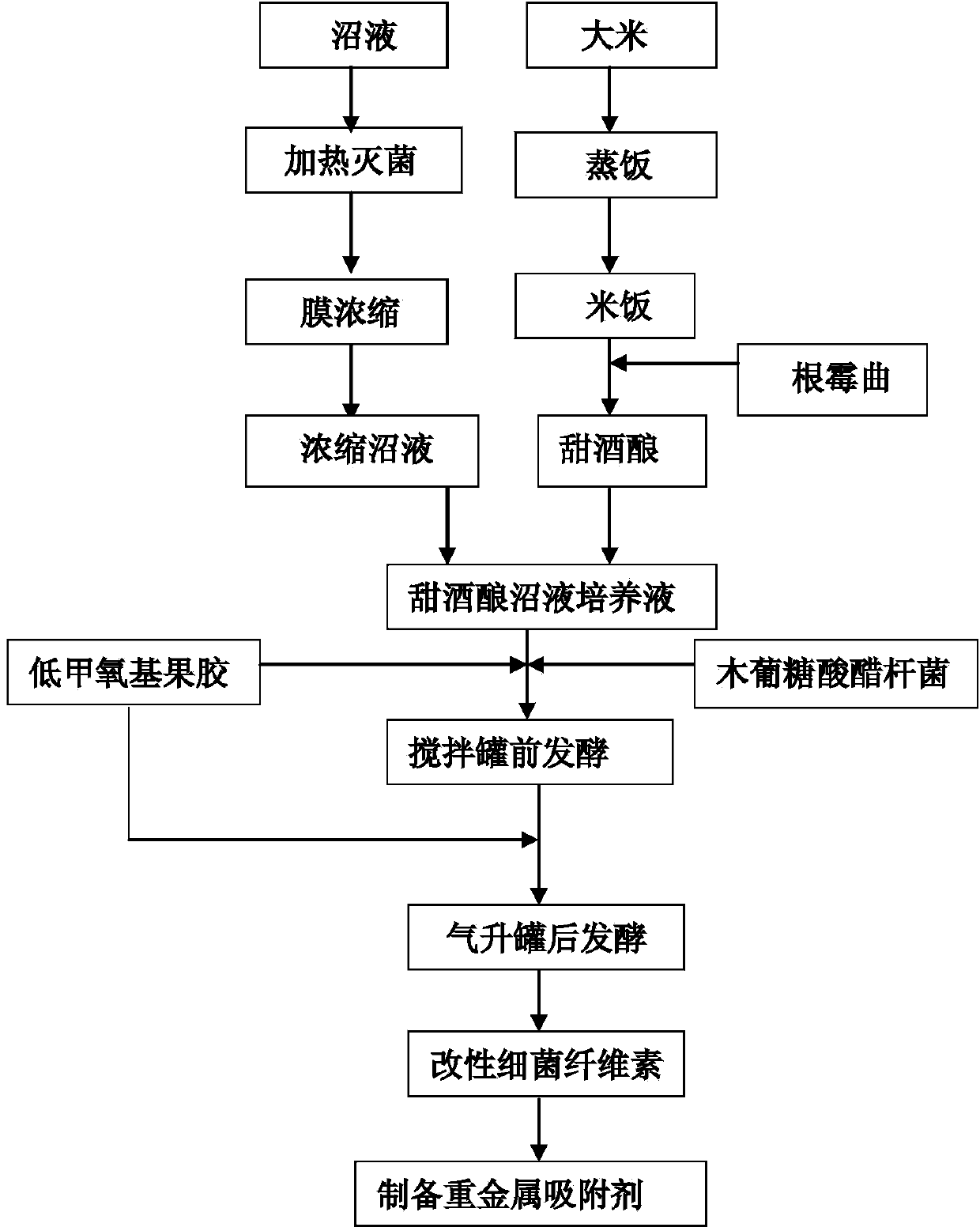

[0030] (1) Preparation of modified bacterial cellulose by two-tank fermentation culture

[0031] 1. Pre-fermentation culture in mechanically stirred and ventilated fermenter

[0032] In a 15 L mechanically agitated and ventilated fermenter, put 8 L of sterilized fermented glutinous rice liquid and 0.64 L of gluconacetobacter xylosus seed solution, and then add 0.40 L of low-methoxy fruit glue solution. Control the stirring speed at 200 r / min, culture temperature at 30°C, tank pressure at 0.04MPa, ventilation rate at 0.5L / L·min, and obtain 8.9L of pre-mature fermented mash after pre-fermentation for 6 days. There will be a small amount of flocculent cellulose in the fermented mash before maturity.

[0033] 2. Post-fermentation culture in airlift tank

[0034]Transfer 8.9L of pre-ripening fermented mash into a sterilized airlift tank, and then add 1.78L of low-methoxyl pectin solution. Under the condition of 30°C, the oxygen-enriched air with an oxygen content of 50-80% prep...

Embodiment 2

[0040] (1) Preparation of modified bacterial cellulose by two-tank fermentation culture

[0041] 1、 Pre-fermentation in mechanically stirred ventilated fermenter nourish

[0042] In a 15 L mechanically agitated and ventilated fermenter, 10 L of sterilized fermented glutinous rice liquid culture liquid and Gluconacetobacter xylosus seed liquid were loaded, and the inoculation amount of Gluconacetobacter xylosus seed liquid was 0.8L, then add 0.5L of low-methoxyl pectin solution, adjust the stirring speed to 200 r / min, pre-fermentation culture temperature 30 ℃, tank pressure 0.04MPa, ventilation rate 0.5L / L min, after pre-fermentation 8 days Obtain 11.0L of fermented mash before maturation, and a small amount of flocculent cellulose will appear in the fermented mash before maturation in the mechanically stirred ventilated fermenter.

[0043] 2. Post-fermentation culture in airlift tank

[0044] Transfer 11.0L of pre-ripening fermented mash into a sterilized airlift tank, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com